Brrrrr...

Managed to get a few hours outside today, but with the wind howling it was so cold my nose was running!

Still, I got some work done, and it all helps me to continue to inch my way toward the finish line.

I bought a new battery clamp, as my original donor didn't have one.

As I now have a Spitfire bulkhead to play with, I won't use my previous plan of "handles & velcro strap" set up.

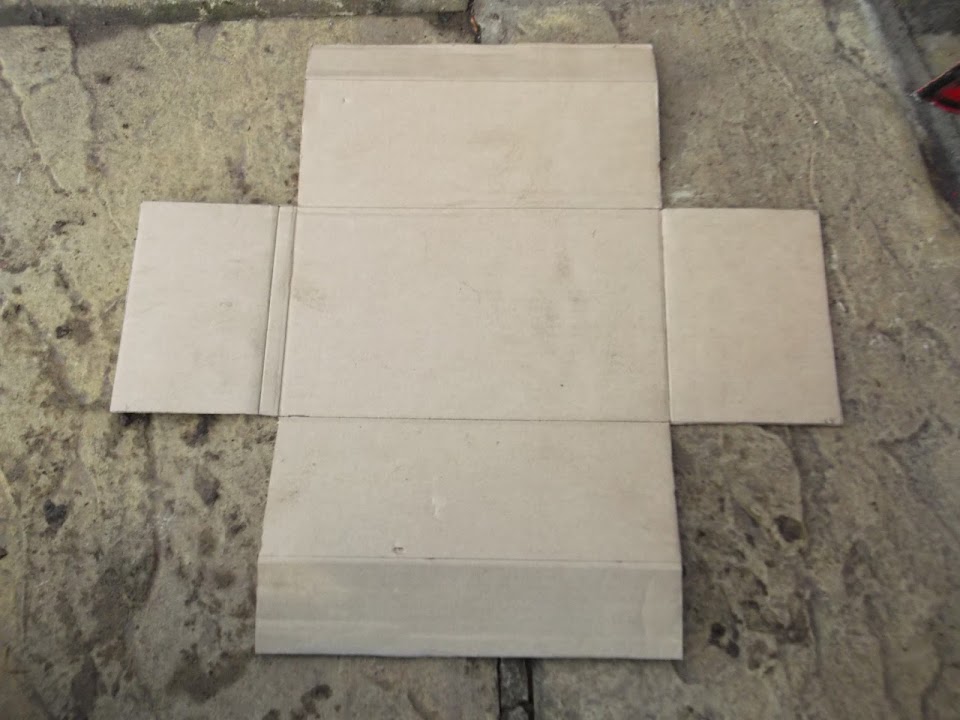

I trimmed the battery box template as I realised I had originally made it a bit deeper than required.

Then it was time to tidy up the section of floor I was going to use for the base.

( There is just no escaping rust on this project! )

After an initial clean up it was looking a bit better.

I then proceeded to attack the panel with my lump hammers & angle grinder to straighten & bend it.

I trimmed a small section off my wooden block so it sat inside the battery box.

In the end I was left with a floor and the rear panel of the battery box.

There is plenty of room for the old battery, or a slightly larger replacement.

I cut off a small section of metal tubing that will be form part of the drain.

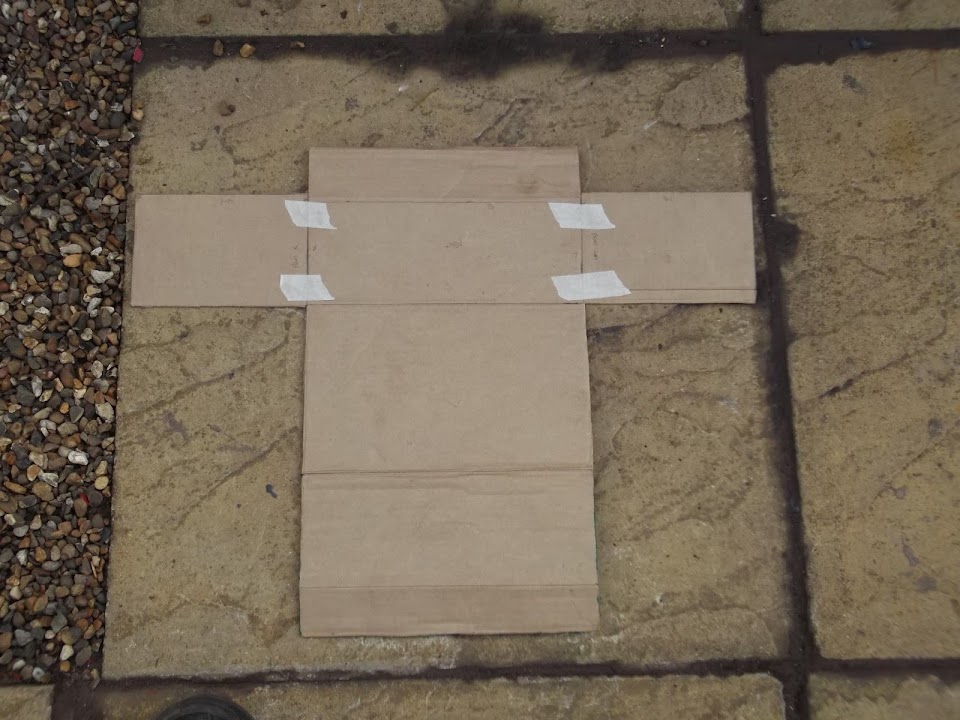

I then re-arranged the remaining sides of the cardboard template.

Which allowed me to mark up the metal & add a bit extra (in red) for tabs on the edges.

I took the time to clean up the edges for welding while the panel was still flat.

However, I then proceeded to hammer the first bend in the wrong direction.

Thankfully I spotted it at this point and cleaned up the other side before finishing the other bends.

This is the two halves of my battery box resting together.

My initial plan was to have these tabs on the inside.

Which would let me weld the "folds" in the floor on the outside.

But it was going to be much easier to weld if I put the tabs on the back of the rear panel.

So a couple of quick cuts later and the tabs could fit like so.

After cleaning the metal some more, I welded the outside edges of the box together before I had to call it a day.

There is still a little bit of work to do on this box, but it is nearly there.

Although I need to do some more preparation work on the bulkhead before I can finally fit it.

Until next time, take care, Paul.