With the Christmas celebrations over and the decorations packed away for another year, it was time to get back down my garage.

Picking up where I left off before the holiday season, I refilled the clutch reservoir and first confirmed I had successfully fixed the leak I had.

It's recommended in the BMW Bentley workshop manual to remove the clutch slave cylinder and mount it vertically whilst bleeding the air from the system.

Clutch bleeding

Clutch bleeding by

Sabrebuilder, on Flickr

Following re-installation of the slave cylinder I confirmed I had a fully operational clutch and to check I had no further leaks I left it for a couple of hours with a piece of wood jammed against the depressed clutch pedal. All good

To prevent damage to the clutch master cylinder I made up this pedal stop from a 10mm bolt and a scrap of steel tube.

Clutch Pedal stop

Clutch Pedal stop by

Sabrebuilder, on Flickr

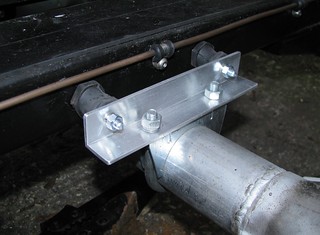

Back in October last year I made up an additional exhaust hanger but every time I saw it in the garage the less happy I got with it and the last thing I wanted was to turn up at the IVA test centre with a detached mounting.

Exhaust bracket

Exhaust bracket by

Sabrebuilder, on Flickr

So, I had to do something better and I then spent a good few hours remaking a new exhaust bracket.......

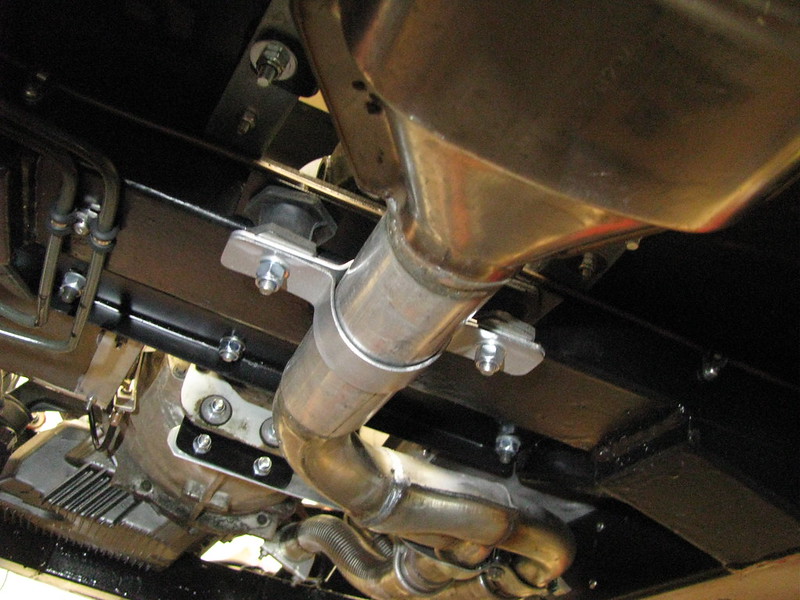

I started by making a two part strap from 2mm thick steel strip which was quite a challenge with only a vice and a lump hammer :-). I used an off-cut of exhaust pipe as a former.

This was then fixed to a piece of angle bolted to the chassis with some substantial exhaust bobbins.

Exhaust mount

Exhaust mount by

Sabrebuilder, on Flickr

Exhaust mount

Exhaust mount by

Sabrebuilder, on Flickr

In all, with painting and fitting, it took me a couple of days but I am glad it is now done.

Moving on, before fitting the gearbox tunnel I thought I would check the clearance of the gear knob to the dashboard. I retrieved the dashboard surround from my loft and temporarily fitted in position.

Shown here in first gear which is clearly not ideal!

Gear shifter

Gear shifter by

Sabrebuilder, on Flickr

Luckily, I have collected a variety of gear shifters so I tried a shorter lower rod.

Gear stick in 1st gear position. Now plenty of clearance for my knuckles.

Gear shifter - shorter lower rod

Gear shifter - shorter lower rod by

Sabrebuilder, on Flickr

Gear stick in neutral position.

Gear shifter - shorter lower rod

Gear shifter - shorter lower rod by

Sabrebuilder, on Flickr

Gear stick in 4th gear.

Gear shifter - shorter lower rod

Gear shifter - shorter lower rod by

Sabrebuilder, on Flickr

Perhaps now a little too short but I think this will be OK, but feedback welcome.

Next week I hope to get the gearbox tunnel fitted and start to install the engine loom. I've also been cleaning up the original windscreen wiper gear in preparation for re-fitting, so more on that next time.

peter.......