10th October 2017, 04:55

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Almost there. Maybe.

Almost there. Maybe.

Before Sunday's sortie to the Cheltenham Literary Festival (two of my moto-travel friends were giving a talk promoting their latest books), I managed a couple of hours or so on the project. The fruits of my labours were more P clips made and riveted in position along the engine bay and over the nose cone for the driver's side gubbins.

Yesterday I started by drilling the holes for the wires which will run into the headlamp pods and fed the wires though. I'm leaving them un-grommeted until the loom's completely wrapped. This left the indicator wires looking rather lonely so I decided to fabricate mounting brackets for the L488s. I decided to have them mounted on the sticky-out bits of the frame where I'd trimmed off (following DVLA guidelines) the redundant parts .

Using the trusted CAD method I soon had their profiles transferred to aluminium sheet. The grommet-sized bit was still in the drill so I made starter-holes and used my 'left hand cut' tin snips to enlarge them to the marked size, just. The holes were about the limit in smallness for this method. A couple of minutes with the bench grinder and a rat-tail file, plus a quick bend in the vice and they were ready for mounting. I used regular 4mm rivets to attach them.

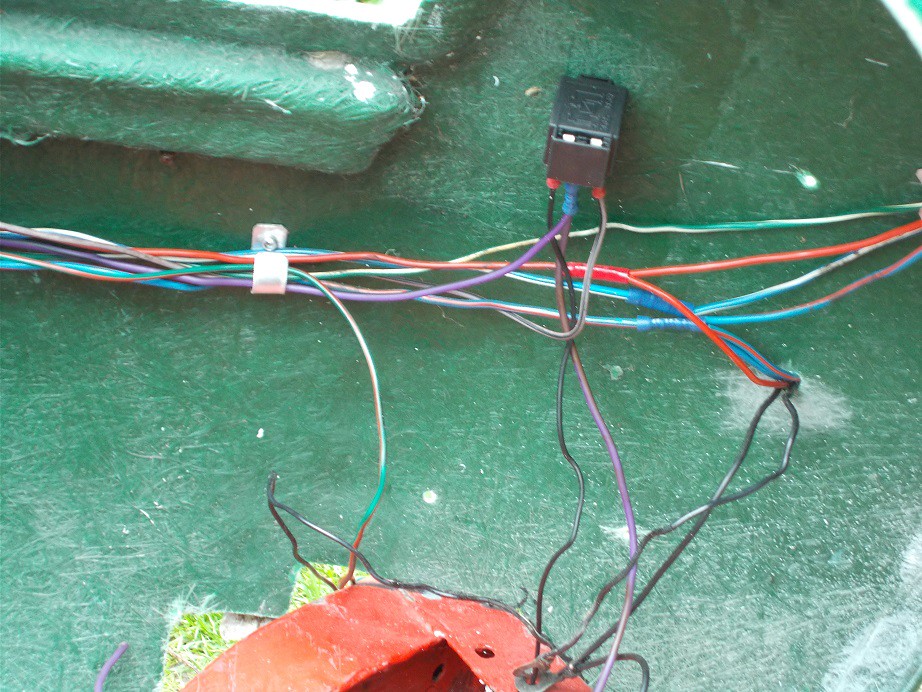

The other day I had ordered my yet-to-be-delivered Stebel Nautilus horn on Ebay. This is the ear-splitting 116db item I fitted to the A352. Scottie's eardrums remember it well from when he tried it in the confines of the man cave  . As the horn button is on the dash, rather than column mounted, I've wired it back to front, as on the A352, with a fused relay. All those decibels need a good few watts! I mounted the relay (it came with a natty little bracket) up inside the nose cone, high enough to be out of the weather. It doesn't look like it in my rather crummy picture, but the purple wires (solenoid to relay, and relay to horn) are 17amp, as the horn's earth wire will be. . As the horn button is on the dash, rather than column mounted, I've wired it back to front, as on the A352, with a fused relay. All those decibels need a good few watts! I mounted the relay (it came with a natty little bracket) up inside the nose cone, high enough to be out of the weather. It doesn't look like it in my rather crummy picture, but the purple wires (solenoid to relay, and relay to horn) are 17amp, as the horn's earth wire will be.

Last job was to tightly cable-tie off the junctions between the various legs of the loom so that, once it's removed, I can bind it accurately. This last photo' shows how the end section runs inside the top of the nose. The tails of the P clips won't be bent right up until final loom installation.

That was it for the day.

Regards, Mick

|