Andy - Thanks for the kind words.

With no car building background I really need to think about things a lot more than most.

But I have decided to try and be very decisive when I start the epic bodywork challenge.

Scottie - Thanks for the women beating tip, but forgive me for not following it.

As for a race to the finish, my money is still on your build.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Only had the chance to do a bit of minor tinkering today...

Bonnet

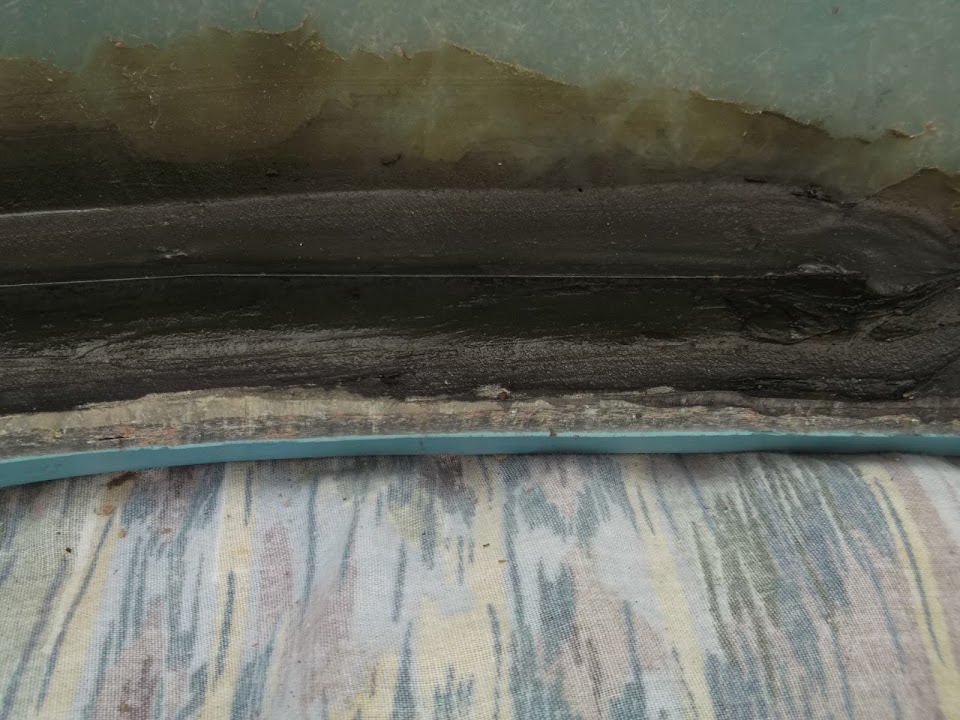

It was an easy job to sand down the bonnet hinges & get some Kurust over the whole "bonded" area.

Hopefully I will get the chance to get some etch primer on this tomorrow.

I was thinking about smoothing out some of the rougher spots with my grinder before spraying.

Although as I was looking at this area in more detail I noticed another potential issue.

This hoop was bonded in at the Sammio factory as an optional extra and there isn't much room for the grille at the bottom.

On the top loop the bonding paste is level with the top of the metal ring at the back, but not the front, leaving a "lip".

But at the bottom, the ring is very close to the "mouth" opening in the bonnet, leaving very little room to locate the grille.

I don't need to solve this today, but I will have to give it some thought at some point.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Bulkhead:

On closer inspection, sorting out this mounting point is going to be a lot of work.

I think the problem is that the holes were drilled to fit a different chassis, not mine.

So I undid all the other bolts that I had previously test fitted & lifted the bulkhead off the chassis.

( After removing the bodywork first & then getting a helping hand from my wife. )

Then I could make a template for the "floating" retaining nuts.

I also reminded myself that the bolts go in perpendicular to the angle of the chassis arm.

A quick check at the bottom of the bulkhead showed that the holes here were not perfect when I got the bulkhead either.

So there will be a round of cutting, fabrication and welding required to fix this once & for all.

But I had no time left to start that today, so the bulkhead was moved next to the rear wheel arches.

That's all for now, cheers, Paul.