First of all, thanks for the feedback gentlemen, anything not covered below, I'll pick up in another post.

( As I have too many domestic chores to sort out today.

)

This is what remained of my thoughts on doors and other news from yesterday...

Door Hinges:

Mike's advice was to provide access to the hinges so they could be tightened up periodically if required.

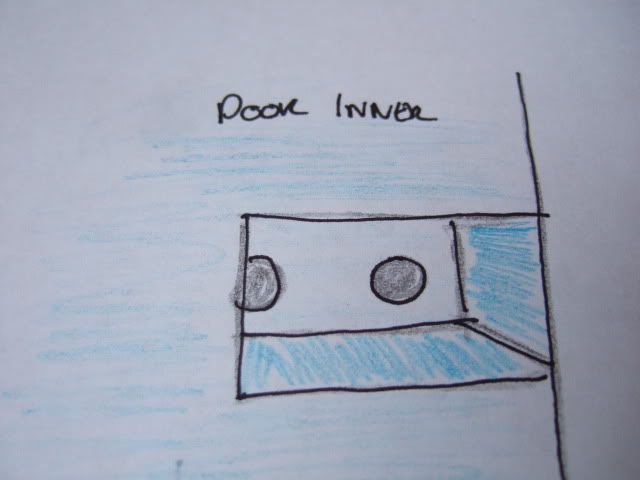

Initially, I intended to cut out sections of the inner door to expose the hinges bolted through the door.

( Please remember that these sketches are from the impressionist era, not tech drawings.

)

This was fine for the doors, but the bolts through the bodywork had the issue of the frame to deal with.

So I figured I would need quite a big access panel to get a spanner behind this framework.

However, I removed all the fixings for the hinges yesterday and noticed a few differences.

Not sure how they fit to a Mini, but there are 3 x 10mm nuts & 1 x slotted head bolt per hinge.

( I was planning to replace the original nuts with Nyloc ones. )

So the question is whether I could use 4 x slotted head bolts (with thread lock) per hinge?

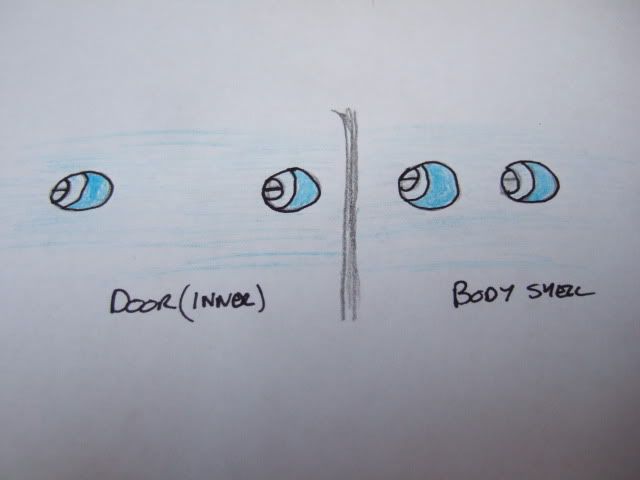

This would mean I would only need simple access "tubes" through both the body & doors.

I would simply need to drill holes straight through the frame if any part of it is in the way.

If these bolts are not suitable, then I would need slightly bigger tubes to accommodate a 10mm bolt tool.

I would look for a very thin T-Bar type tool as I only have a large socket set at the moment.

Door Cut Out & Door Profile:

There are two issues at play here, the first is connected to the doors (obviously).

But the second, is wanting to more the body forward to fix the rear cockpit's "hump" pressure point.

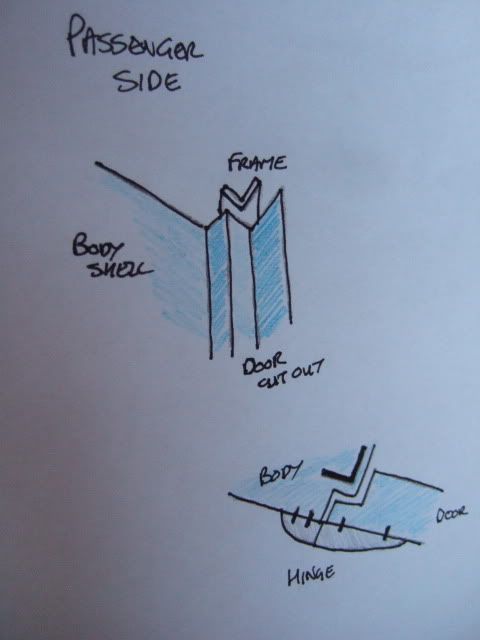

The bad news is the door cut out hits the frame, but the good news is the space "behind" the frame.

I couldn't get a decent photo, so here is my hand in between the back of the frame & side of the body.

This means that I could retain the original line in the body shell that turns into the opening.

But then cut out the rest & build a new step in the opening to go around the frame.

This should allow the body shell to move forward & provide a better door closing "lip".

Hopefully these basic drawings might make more sense that the words above...

Clearly there is a lot to do to create matching "ying & yang" profiles between the door & opening.

I will need to think about the trailing edge of the door some more to take account of the latch required.

Cutting Fibreglass:

It looks like I need to either improve my jigsaw technique or get some heavy duty blades.

Removing the two door opening "lips" yesterday broke 4 blades designed to cut metal.

Spitfire Rear Section:

Spitfire Rear Section:

I am now on a quest to follow

DonnySoutherner's solution for the back of my car.

This also raises the possibility of a small "cubby hole" for storage linked to my rear cockpit access panel.

Spitfire Graveyard:

Spitfire Graveyard:

They supplied the above section & I sent them some photos before I rang.

I figured the phone conversation would be easier if I knew we were both talking about the same thing.

Unfortunately, they had just been forced to clear their yard and didn't have anything I could use.

SpitBitz:

SpitBitz:

I've not used this company before, but gave them a try after missing out at the Spitfire Graveyard.

Again, I sent a photo ahead before giving them a ring and this worked out well as they can supply a section.

However, I need to visit them to check the condition & agree the final cutting points.

So that will be a job for next Saturday morning.

Sorry for the flying visit, I'll be back either late tonight, or tomorrow evening, Paul.