|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

17th July 2014, 19:23

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - Cheers mate, I do learn a lot from your build thread.

( Plus Mr T, Mac, Oxford, etc. )

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

What have I done now? - Part 1

It was the afternoon before I got the chance to do anything on the car.

It started off simply enough, with the first coat of paint going on the chassis repairs.

Then for some reason I decided it was time for my body shell to have some drastic surgery.

Those of you who don't want to see even more fibreglass butchery should look away now.

My number one problem is the (MOT failing) issue of the rear passenger arch not covering the wheel.

I know Mac resolved this as part of his repositioning of the wheel arch itself, a very neat bit of skill.

I needed to keep things simple and I will sort out the wheel arch openings as a separate job.

So my solution was to literally cut the back of the car into two along this line!

I have also decided to fit the second hump as this will help disguise the mess I am making.

( I hope.  )

I clamped the body shell to the framework.

Then make the cut...

I'd already prepared a set of brackets to hold the two halves together.

But it quickly became apparent that these were not really up to the job.

So I dug out the original Cordite fibreglass dash section that looked like this.

Then I chopped it up to make bigger support brackets like so.

I must say that my new "chuckless" drill really came into its own today.

I was constantly switching between these three bits.

- Holes in brackets

- Slightly smaller hole in body shell

- Tech screw fitting

In order to keep the shape, it was literally one hole / screw at a time.

End of Part 1...

|

17th July 2014, 19:25

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

What have I done now? - Part 2

Eventually I had really created Frankenstein's monster.

The gap stretches from 1.5" at the cockpit end, to 3" at the tail pipe end.

However, the body shell actually looked a lot better when viewed from the side.

The wheel is now safely tucked in under the arch too.

Although I still need to come back and mark up the wheel arch opening for some adjustment.

Plus the hump will not hide all of my sins.

Project Hillbilly

Project Hillbilly

Today was a major step in the right direction in terms of actually finishing this project one way, or the other.

Is the body shell now in perfect alignment? - No.

Is it in a better shape now, than it was before? - Yes

I can not win ever symmetry battle with this kit, but I intend to win the war!

With a bit of luck I will get the chance to add some fibreglass repairs to this gaping wound tomorrow.

So until next time, take care, Paul.

PS

I will come back and reply to other build threads later on, as I really need to rest now.

|

17th July 2014, 19:29

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Phew major surgery mate! Make sure you tape up the gaps as you would be amazed how easy all your fibreglass will sag through the gaps. Looks like I may be doing something similar to the bonnet on Saturday myself :-)

Keep at it

Mac

|

17th July 2014, 19:57

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Paul, I salute you!

Mega hacking about going on in your garden!!

Looking good, you'll get what you want now!

The added bonus also is, that it gives you the confidence to do other "un-do-able" tasks.

It did with me anyway.

|

17th July 2014, 20:12

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

Well done, Paul! I'd put in an order for a roll of CSM and 5l of resin if I were you!

|

17th July 2014, 20:33

|

|

Senior Member

|

|

Join Date: Jun 2011

Location: birchington, kent

Posts: 1,769

|

|

Great fun, i can't wait to have a go... i hope my bodyshell is f****d too.

|

17th July 2014, 21:38

|

|

Senior Member

|

|

Join Date: Dec 2013

Posts: 839

|

|

Just logged on to check out what you are up to Paul and WOW major bit of body work in progress there matey, this will be interesting as i have no doubt that something similar may have to be done to my body/bonnet kit when it arrives.

Keep up the interesting reads and good luck.

|

18th July 2014, 09:13

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Thanks for all the replies gentlemen.  Mac

Mac - Thanks for the "sagging" tip & I look forward to seeing what you do with the bonnet.

Scottie - Your "un-do-able" tasks comment really struck a cord with me.

Never in a million years did I think I would be doing something like this when I first started out.

Oxford - Well I am certainly working my way through the first big roll of CSM I bought!

Gary - That is the whole irony of my Cordite project, as your Spyder is in better shape.

Apart from taking a slither out of the bulkhead and maybe re-profiling the arches your car should be fine.

Swifty - The good news is that Mac's re-working of the Navigator buck means your body shell is OK.

The bad news is that the bonnet will need at least some work to fix the driver's side wheel arch.

I must confess I will also be picking my battles with the bonnet and some "quirks" will probably remain.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Well the thunder clouds seem to have moved on, so I'd better get outside...

|

18th July 2014, 18:42

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Ice Cold In Wembley - Part 1

This image came to mind when my work area became a sun trap for the hottest part of the day (90+).

So I will be putting a can into the freezer later as a small reward for a productive day...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

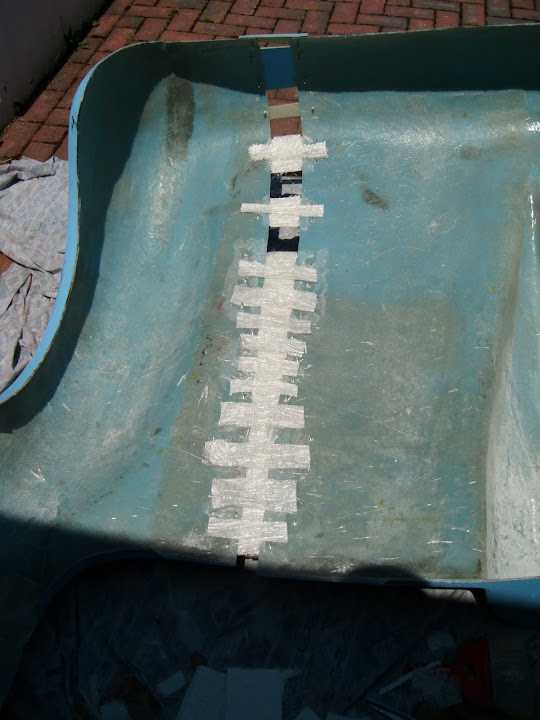

Healing the body shell:

Thankfully my wife was around to help me carefully remove the body shell and turn it upside down.

I wanted to avoid the fibreglass "sagging" that Mac mentioned.

So I decided to start repairs on the underside of the support brackets.

Note:

I had already roughed up the edges using my grinder before this photo was taken.

The plan was to put some brown parcel tape on the inside surface.

Then two layers of CSM inside the gap.

Followed by some strips of matting going across the gaps, in between the screws.

And a bridging layer across the whole lot, whilst still avoiding the screws.

However, as I was cutting out the matting another plan came to mind.

In addition to putting tape on the brackets, on the flatter surfaces I could also tape over the gaps too.

I will need to come back to sort out the curves at the rear end of the car another time.

So just the two layers of matting in the gaps + the "cross stitches" looked like this.

I then laid everything out ready to start the fibre glassing production line.

As it turned out, I changed my approach slightly as I was going along and it ended up as:

- 3 layers of matting in the gap

- 1 thin layers along both edges covering the body shell and the matting in the gap

- 1 layer across the body shell and gap in between the fixing screws

- 1 layer over the top of everything else, working around the screws

So this was what it ended up looking like by the time I had finally finished.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Second Hump:

When I first thought about fitting the spare hump that AndyP57 kindly sent me I expected to cut the body shell like this.

I figured that I would be fibre glassing inside the hump to hold it into position.

Then Mac showed how he fixed his humps to the surface of the body shell without cutting it.

I will try follow this approach myself as it will allow me to add extra layers of matting on the sunny side of the body shell "gap".

( Well on the bits that will be covered by the hump anyway. )

So I took my hump...

And removed the moulding edges.

I still need to convert it from a driver to a passenger hump.

( By extending one side and trimming the other. )

But will be a job for another day.

End of Part 1...

|

18th July 2014, 18:43

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Ice Cold In Wembley - Part 2

Silencer Exits:

I still need to cut the body shell to make room for the twin tail pipes.

But before I did that, I wanted to start work on the replacement body shell panel.

So I started with these.

Note:

Other beer and squash brands are available.

Added some parcel tape.

Then three layers of matting.

When that was set, I could remove my moulds and was left with this.

Before a quick trim gave me these.

The beer can is actually quite a good match for the tail pipe.

Whereas, the Vimto bottle has produced a slightly wider curve.

Sorry that the photos do not make it very easy to see the difference.

Which ever one I choose will need to be 'glassed into the body shell here (ish),

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

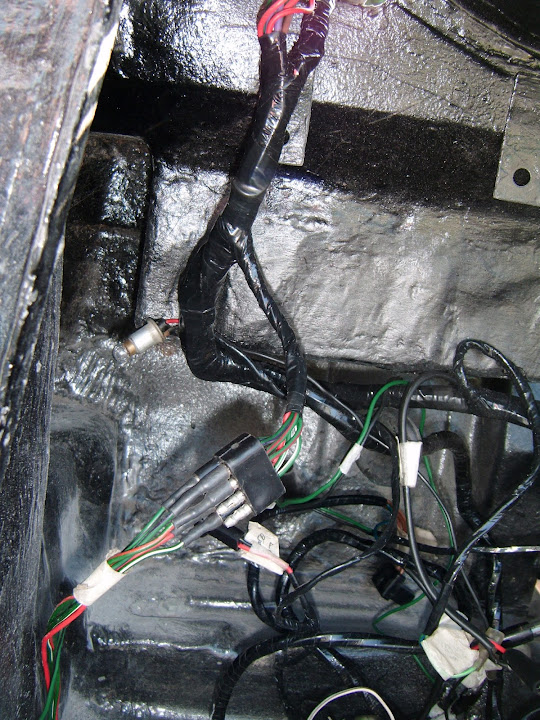

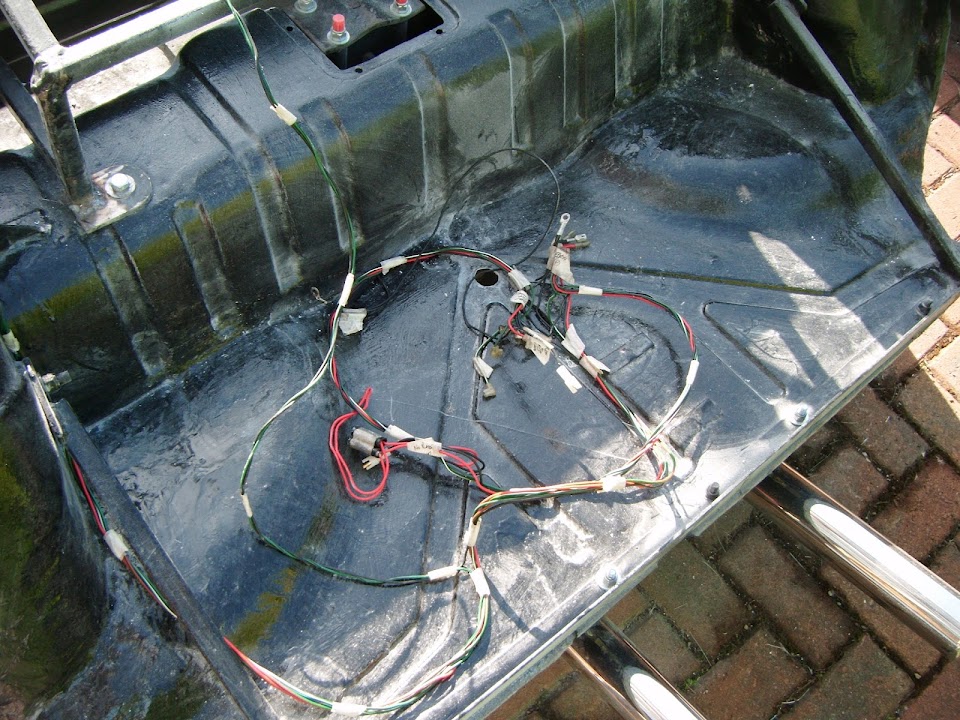

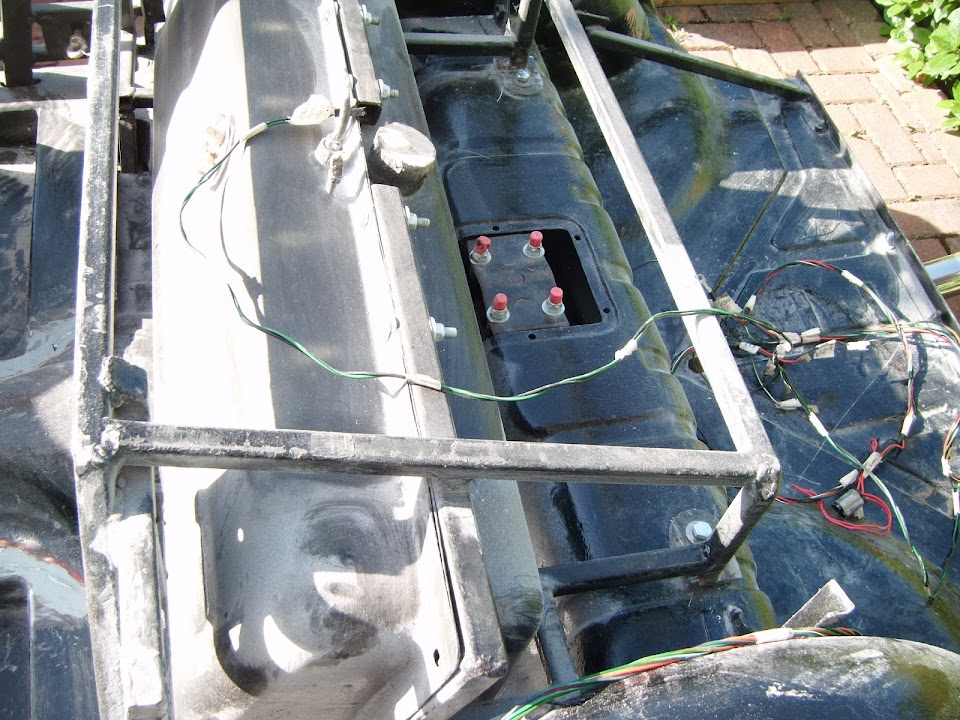

Rear Wiring Loom Routing:

One of the jobs on my bulkhead "To Do" list is to provide an exit point for the rear wiring.

So I dug out the loom and poked this section through the bulkhead.

This let me see where the rear wiring is in relation to this point.

( It is the unwrapped set of wires, bottom left of the photo. )

So I think this may be my best bet, as it is a single panel deep at this point.

There is a lot of "boxed" sections around here, e.g. the "A" pillar.

This would give me quite an easy route for the wiring to take.

I might need to extend one of the earth leads, as this is the standard wiring loom for the fuel tank gauge.

So it should be quite straight forward to shorted the route this takes.

Note:

I did plan to run the wires along the higher frame rail, but will be using this frame rail to provide extra support to the sides of the cockpit.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

One advantage of the excessive heat was the fibre glass reached the initial setting point very quickly.

So by the time I had packed everything else away, my wife & I could safely put the body shell back into position.

Hopefully it will continue to set under the covers, which will also protect it from the next rounds of storms.

Until next time, take care, Paul.

|

18th July 2014, 20:04

|

|

Senior Member

|

|

Join Date: Jun 2011

Location: birchington, kent

Posts: 1,769

|

|

your fibreglassing getting rather slick, it must be where you work on it everyday. i will be making a few more cuts than you think...

|

19th July 2014, 07:22

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

How many other groups of kit car builders would quite so happily take a cutting disk to their prized kits?

I know there were some.... Niggles..  with these kits, and yes, it would have been nice for them to have been 'perfect'. but for what we paid I think there are quite a few of us like you Paul, who started these as novices and have got _so_ much more out of our builds "because" of what we've gone through

I know that personally there is no way I would have quite so happily hacked about my Countach if I hadn't dome my Spyder first. As it made me realise, if its metal you can cut and re-weld it. If its fibreglass you can cut and re-glass it. And there's nothing to be afraid abput , as you are now showing in quite dramatic style

Keep going matey, you're nearly there!

Dave |

19th July 2014, 16:19

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Gary - I must confess that I was very happy with how the tail pipe moulds turned out.

I look forward to seeing how you get on with your own "cutting and shutting" work.  Dave

Dave - Thanks for the encouragement and I have certainly learnt a lot building this car.

Obviously I wasn't expecting to need any of these new skills building a simple "re-body" kit.

However, I feel much happier since I decided that any standard of finished car will be better than an unfinished one.

Whilst I avoid setting deadlines, talk of a group drive on the anniversary of Mr T's MOT really appeals to me.

12 months from now sounds like a long time, until you realise it has taken me 2 years & 3 months to get this far.

So I will keep chipping away and see what stage I can reach before my 3rd winter sets in.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Some Basic Prep. Work:

The weather man seemed to be struggling to pin down when the thunder & lightening would return today.

As I just couldn't risk getting caught out by a heavy downpour with stuff laid out every where I didn't expect to do any car work.

Instead I was planning to make an early start on Sunday morning, but thankfully remembered I can't use any "noisy toys" at that time.

So given it was still sunny, I took a chance and nipped outside.

Although the first job of the day was to prune my "garage wall".

Then I simply peeled off the covers from the rear of the car & threw a dust sheet over them.

I removed the screws from a number of the supporting brackets & carefully removed them.

Then I ground down the gel coat either side of the repair and keyed the top surface of the repair too.

By the time I'd finished sweeping the dust off the car, the drive was a mess.

But before I cleaned up, I drilled some holes and put back two of the brackets I'd removed earlier over some of the remaining gaps.

Then it was time to tidy up the drive and put the covers back on.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

With the sunshine still on my side, I then went and set up shop in the back garden.

This isn't a great photo, but I was trying to show the different depths on each side of the spare hump.

I cut a length of hard board & applied some parcel tape to the bottom edge.

Then I drilled some hole in the board & hump before tech screwing it all together.

One thing I am now currently toying with is putting the passenger hump in the centre of the passenger seat, not offset like the driver's side.

I figure if anyone is brave enough to get into a car I have build, they should at least have a decent head rest.

This idea may make blending in the hump with the body shell easier, or more difficult, so I will have a proper look at it another day.

Until next time, take care, Paul.

Last edited by Paul L; 20th July 2014 at 14:23..

Reason: Typo

|

20th July 2014, 12:11

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Flying Visit...

Went for a short run around the block this morning while the rest of the family were still in bed.

These days I always have one eye on the skips that I pass, in case I could recycle something for my build.

Well today was a complete result when I passed a skip with 3 car wheels left out to be taken, one of which looked "just right".

So later on I went back and collected this 13 inch wheel, with a 185/70 tyre fitted (my wheels have 175/70 tyres).

I will be using this to make a mould and build a new "standard" wheel arch opening.

Then I can cross check all four corners of the car against this and "cut & shut" to match.

Well, that is today's theory anyway.

Which leads me nicely to the next bit of surgery on the rear of my body shell.

I am actually really happy with how the rear passenger arch now covers the wheel.

Whilst the driver's side arch covers the top of the wheel, it "tucks in" towards the back.

This is something I will sort out when I am tackling all the other body shell jobs in the back garden.

These is one small benefit from this work, which is a bigger area to set up my rear number plate & rear lights.

For now, I needed to add some fibreglass filler to the gaping wound I had in the body shell.

My idea to use just parcel tape to bridge the gaps between the undersides of the fixing brackets wasn't a good one.

As it didn't support the edges as well as the fixed brackets did, so I dug out any flaky fibre glass.

Then made sure that the filler was pushed into all the gaps (like someone tapping down a concrete "slab").

While that was drying / setting on the front drive, I did some fibreglass work in the back garden.

I build up the edges of the spare hump, covered the new & old edges + added strips in between the screws.

With the last bit of resin I also started to re-enforce the rest of the hump from the inside.

You can just about see the two rectangles of matting I've added in this photo.

I will eventually beef up the whole hump from the inside before it gets fitted.

I also made a second "beer can" tail pipe mould.

Anyway, that's all for now as I'm taking my family out for a pub lunch, cheers, Paul.

Last edited by Paul L; 20th July 2014 at 19:22..

Reason: Correcting tyre profile numbers

|

20th July 2014, 18:53

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

The Penny Drops...

Whilst doing a bit of forum research some aspects of what I am up against have finally fallen into place for me.

( I may have mentioned I can be a bit slow when it comes to working out this car building lark.  )

Something was bothering me about the rear wheel arches after I posted these photos earlier.

Passenger Side:

Driver's Side:

So obviously I went back to check in Mister Towed's threads and this photo explains part of my problem.

It appears that the original Spyder design included the "swept back" profile that exposes the tyre as per my driver's side above.

Which then brings me back to Mac's photo of the two halves of the old Cordite buck.

Previously I'd tried to illustrate the difference using my set square.

Driver's Side:

Passenger Side:

But what this meant in practical terms didn't really hit until now:

- The driver's side has a bigger sweep than the passenger side.

- So when I moved the passenger side out to cover the top of the tyre, the rear of the tyre was covered by the shallower body shell profile.

Which obviously explains why the two sides still don't match after my radical surgery.

This is turn reassures me that I am not going mad and these days at least I know I can fix this.

The other photo from Mr T I want to use is this one from when his body shell was bonded into position.

You can see the rear arch sweep, but the real bonus for me was see the fact the wheel arch has no "lip".

Both my rear arches still look like this.

As I was never sure if I was meant to cut this lip off, or not.

Cutting it off will make changing the profile of the rear arch opening much easier for me.

As I can extend the fibreglass from behind and re-enforce the whole area with extra matting.

Whereas, changing the profile and building a matching lip would be a bit tricky given my skills.

Sorry for yet another "thinking out loud" post, but this does help me plan the work I need to do.

Cheers, Paul.

|

20th July 2014, 20:18

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, just my opinion but I personally wouldn't remove the lip totally, having the lip at 90 degrees to the arch increases its rigidity massively, removing it totally will make the whole arch area a fair bit less stable. Keep at it mate.

Mac

PS also just looked closely at your body cut. Bit late now but if you do any more major mods I would advise putting at least one layer of chopped strand body side before using filler.

|

21st July 2014, 07:38

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Your feedback is always welcome.

Sorry I should have explained the filler over the "wound" a bit better...

I will be sanding back that initial round of filler pretty hard.

Its main purpose was to "fill in" the small voids created by me relying on just parcel tape for support.

However, I will also leave a thin layer of filler across the area I have covered in an attempt to "seal" it.

Then I will mark up the position of the spare hump on top of the body shell / wound.

This will give me a "footprint" for some extra layers of matting on the "sunny" side.

This should cover:

- The cut area

- The filler

- The body shell on either side of it.

So at least the area under the hump should be pretty solid by the time I'm finished.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Can I ask for some more advice regarding the lip on the inside of the wheel arch?

I've seen Mr Bond keep, but reposition / re-shape the lip like so.

I was also planning to do something like Scottie and join my metal inner Spitfire wheel arches to the body shell.

( Not 100% sure how I will be doing this at the moment, but I worry about that another day. )

So would joining the arches to the body shell provide the same rigidity as keeping the lip?

Or would a "belt and braces" approach of keeping the lip and joining the arches be best?

Thanks, Paul.

|

21st July 2014, 08:54

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

This may help your ponderings.

On my Spyder i went for a really low stance, in retrospect possibly too low! and I had mildly trimmed down the lip on my wheelarch when i initially fitted the shell in order to give the tyre clearance and here's how it was originally:

But i did get a bit of fouling on the lip as, as you've found, it wasn't as wide as ideal (especially with my 15" wheels fitted) and i ended up trimming it down even more after a few months driving as i was getting some wheel rub on the lip. Here's the best pic i can find to explain, the 'grey' on the lip is where it'd rubbed. Not much to look at, but sounded dreadful when i hit a bump in the road until i did a bit more trimming!!

|

21st July 2014, 12:12

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Wheel and tyre size makes a difference where rear arch fouling is concerned. I had no issues with 175/70/14 tyres fitted, but did initially suffer some fouling to the n/s rear arch when I carried a passenger once I'd switched to 175/80/14's.

Removing the lowering block has cured the problem 99% but it still scuffs slightly over major bumps with a passenger. If I hadn't removed another leaf from the rear spring I doubt it would do that, but then the ride quality would be a bit firm. I just try to drive more carefully on bumpy roads when it's two up.

|

21st July 2014, 16:39

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, if I have to do the front arches in the bonnet I will do something similar to Bonds build. Don't forget like all areas of life there is always more than one way to skin a cat.

Mac

|

|

Currently Active Users Viewing This Thread: 2 (0 members and 2 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 17:05.

|