Mac - I'll hang on to those brackets a bit longer, in the vain hope of getting a reply from the DVLA.

Thanks for the heat gun tip, as I saw

tlrtone use a thin fibreglass sheet as a basis for his bonnet scoop.

So I might give that a go and see how I get on for now, rather than get professional help.

Scottie - If I chopped the bulkhead down to match the bonnet shape I'd cause other problems.

I would quickly run out of space for the dials, steering, heater hoses, etc. even the fuse box would be in the way.

So I am stuck fixing one problem while causing another problem somewhere else for a bit longer.

Ed - This build has been hurting my brain for a long time now, but this is something else.

I think that uPVC strips may be an ideal way for me to build up some of the shapes I need.

Mr T -

Are you sitting comfortably? Then I'll begin...

Well my plan for building this kit certainly didn't survive first contact with the Spitfire rolling chassis!

Bizarrely, my decision to use the Spitfire bulkhead actually slowed the build down and made it harder to do.

However, given all the problems I had, I really felt this was the only way I could make the kit work at all.

If you remember

AndyP57 effectively shut the Cordite production line down and started again.

The new Navigator model has a different body shell and different internal framework to go with it.

What I should have done is return the whole lot as "not fit for purpose" and got a refund.

But Andy had only just taken over the company this mess wasn't really his fault.

So I decided to support him, keep the kit, and try to build it to the best of my ability.

I would use the faults as an excuse to learn how to weld and work with fibreglass.

Clearly I had no idea just how much work I would be required to sort out all the issues.

I know that the "revised" lines of my car will not look as good as a "standard" Sammio / Ribble.

But if I can ever reach the point when this car is on the road, I'll live with being the "inbred, hillbilly cousin" of the family.

I certainly hope I am not coming across as someone simply ignoring good advice.

I really do appreciate all the time and effort people have taken to reply to this build thread.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

A Start...

I dug out my brake pedal.

Then bolted the master cylinder to it just so I knew where the top of it would be.

Then I marked up the hardboard template I made the other day using the bulkhead as my reference.

I then realised I could use the "off cut" from that template on this part of the bulkhead.

So I marked that up too, then the two panels were ready to be jigsawed.

After cutting they looked like this.

Then after applying some parcel tape & weighing the ends down I was ready.

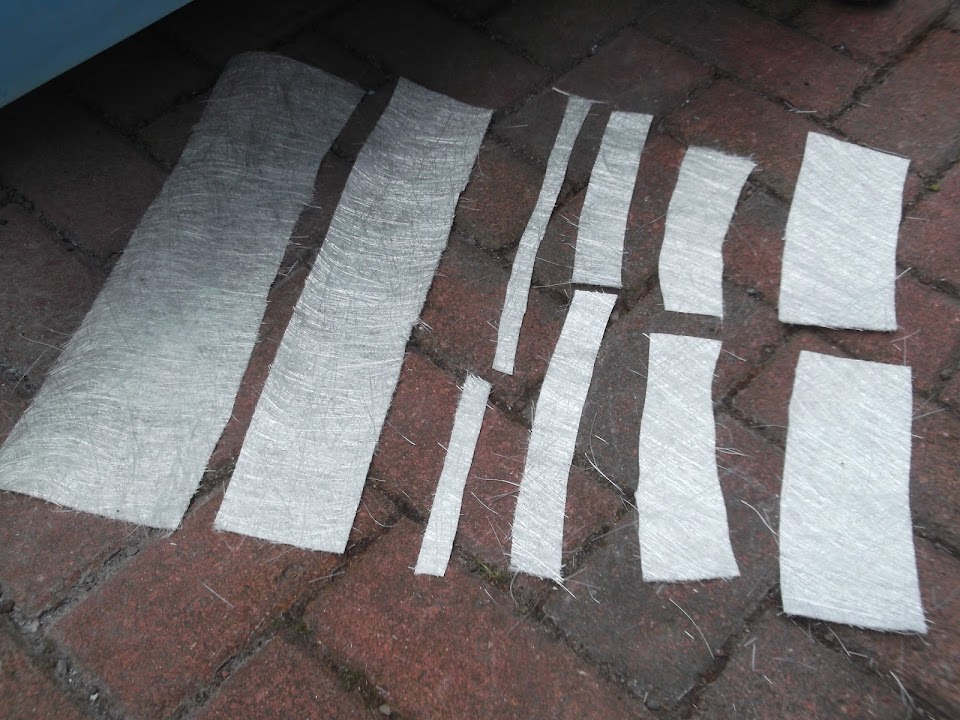

I cut out a selection of matting for the start of the centre section.

After the second round of fibreglass I had this to show for my efforts.

Once that was set I added an off cut of hard board to the top of the master cylinder.

This should ensure that the body shell clears this with ease.

Then I was able to weigh down the ends of the body shell like so.

So that the hardboard was pinned down by the top edges.

Note: I needed to do a bit more trimming of the body shell "lip" so the hardboard could pass through.

After a couple of layers of matting had been added I was left with this.

Now it has taken me a long time to get my head around how this will work.

But the piece you see above is both the bonnet lip and a body shell locating edge.

When the hardboard is removed I will be left with something that fits on top of the Spitfire bulkhead.

This will be the "unseen" bottom surface of the scuttle, regardless of the final shape on the top surface.

Note:

I can't join the two sides of the body shell to this new piece until the hardboard is removed.

But I will be adding some more matting over the top before I worry about doing that bit.

Finally I clamped a thin strip of hardboard to the bonnet to get a better idea of different profiles.

The gap is around 4 cms at its biggest point (centre of bonnet on left of photo, edge of bonnet on right).

After today's effort I am reasonably confident I can re-join the two sides of the body shell back together which is at least something.

Until next time, take care, Paul.