|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

2nd June 2013, 18:43

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

OK, going back a bit to start with the previous replies (which I really appreciate).

AndyP85 - I am really looking forward to seeing the Navigator MkII.  AndyP57

AndyP57 - I am sure if these brackets are built into the frame design they would be neater / simpler.

I guess one issue would be that some customers might prefer normal seat belts compared to harnesses.

So maybe the bolt in option would allow you to cater for both, as the side mounts would be common?

Nike 55 - Cheers Nigel, we should meet up one of these days for a Sammio group therapy session.  Mister Towed

Mister Towed - Thanks, I will go with a higher position, see new photos below.

- - - - - - - - - - - - - - - - - - - - - -

Sunday - Part 1:

This has turned out to be quite a packed day, so here goes...

Started the morning with some domestic chores before heading out into the back garden.

I didn't trust the clouds forming last night, so I had thrown a cover over the frame...

But the first job was to get the first coat of paint on the petrol tank.

The Kurust had left its usual coat of dark blue / black everywhere...

I started on the bottom of the tank...

Using a not so high tech prop to keep it at the right angle...

Then it was off to Sainsbury's, except that my car was as dead as a dodo.

No time to worry about that now (I take the train to work) so I used my wife's.

Then it was back into the garden to have another look at the position of the rear seat belt bracket.

This was the highest I could get the existing bracket to fit without a complete redesign...

( Note the cardboard template is in the original position )

I put the seat & harness into place for a quick check and this was a no go.

Even though the bracket will be further back when fitted, the eye bolt will foul the seat back...

So I tried this as Option 2, which is a bit lower, but still higher than before...

This gives better clearance to the back of the seat...

And the straps are lower too, so that should leave the strap, not the adjuster, over my shoulder...

Question

Question Is that going to be high enough?

( Looking back at these photos again, it does look like I could edge it up a bit more. )

Then it was time to start constructing the side seat belt mounting brackets.

So it was back to clamping things together...

But no sooner had I started and the rest of the family wanted to go out for lunch.

They have first call on my time, so after a quick change we went down the pub.

I was on my best behaviour and didn't drink as I knew power tools were waiting for me.

I'll be back with Part 2 in a minute...

Last edited by Paul L; 9th September 2019 at 09:00..

|

2nd June 2013, 18:48

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Sunday - Part 2:

The first job after lunch was to flip the petrol tank over and paint the top side...

Thankfully this paint becomes touch dry quite quickly.

But it still needs 24 hours before you can put a second coat on.

So while I had the paint brush out, I gave the rear section of the rear frame a coat too.

This was mainly to cover the parts where the tank will bolt in.

Then it was back to welding...

I am building these is a slightly different order to allow me to make sure they fit.

So the plate itself when in next...

To avoid over heating the welder, I am leaving sections to finish off another day.

As long as everything is held in place for now, I will keep going.

Next it was time to set up another workshop picnic area around the frame...

Then I clamped the first part of the bracket to the frame...

This is the rear view where the bracket crosses the original frame...

Which is why I had cut out a notch to let it sit better / get welded in...

Once that the first welds were done, the clamps could go...

And the top section could be added...

At this point I could take the measurement I needed to cut this out...

And clamp it in place...

Once that was welded in, I could move everything over and go through the whole process again on the driver's side.

Eventually I was left with my two over engineered brackets in place...

This was around 6pm, so to avoid disturbing my neighbours anymore I called it a night.

Only took 20 minutes to pack away this time.

Mind you I need to go back out later on to cover the frame for the night.

Plus I will move the petrol tank into the Summerhouse, as I've left that in the evening sun...

It is hard to believe just how much work had gone into those brackets.

( And I still got to finish welding all the sides / edges! )

Plus I am sure someone who knew what they were doing could find an easier solution.

But this option does allows me a lot of tolerance for my "beginner" welding.

As always, I still expect to get more done than is possible.

But this is definitely a step in the right direction for me.

Until next time, take care, Paul.

Last edited by Paul L; 9th September 2019 at 09:03..

|

2nd June 2013, 20:18

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Nice work Paul, personally fabrication is what i get the best satisfaction from. Just one point i noticed, second picture down, the rear uprights of the frame have open ends, you may want to consider either welding a cap on to seal them or alternatively drill a hole in the bottom otherwise they will fill with water over time (presuming you will ever drive it in the rain :-)) and rust away from the inside out.

I have a few slack days this week so am hoping to make some progress on mine and if the gods are with me might even get the engine fired.

|

9th June 2013, 17:54

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Viatron - Cheers Mac.

Although ironically I picked the Cordite over the Spyder as it was supposed to require less fabrication.

Still, this way I have learnt to weld (to a fashion) and there is certainly a sense of satisfaction in making stuff.

The only downside is the time it takes, as this is all new stuff to me and I am very slow at the moment.

I have made caps for the ends of the frame (see part of the following updates).

Is there anything else I need to consider in terms of preventing rain / water ingress / damage?

For example, did the "rubber rings" between chassis & body shell also help keep water out?

- - - - - - - - - - - - - - - - - - - - - -

Making Hay While the Sun Shines - Part 1

It was been an odd sort of a week for me as I had a few days off work ill in the middle of it.

But I was able to take advantage of the nice weather before & after this short forced break.

So although I haven't been updating my build thread, there has been some progress to report.

I've grouped the work done over the last week, or so, into a few simple headings.

But due to the forum limit on photos per post, this will take a few posts to cover everything.

Petrol Tank:

With the first coat of paint dry, I gave the bottom of the tank its second coat...

When that was dry, I flipped it over and gave the top half of the tank its 2nd coat...

In addition, I gave the rear frame work where it was going to be bolted in a 2nd coat...

Eventually, it was time to bolt the petrol tank back into its final resting place...

I used extra washers on the driver's side to stop the petrol tank fouling against the frame.

( As obviously the frame work supporting the petrol tank isn't square.  )

I even remembered to stick a bit of protective foam into the narrow gap between the two...

- - - - - - - - - - - - - - - - - - - - - -

Lowered Floor Pans:

The first signs of light surface rusting were beginning to appear on my bare metal floors.

As I had finished welding up the pin holes in the passenger side, that was first to be treated.

I rubbed down the underside surface & tidied up the edges were I had cut the floor to fit the frame.

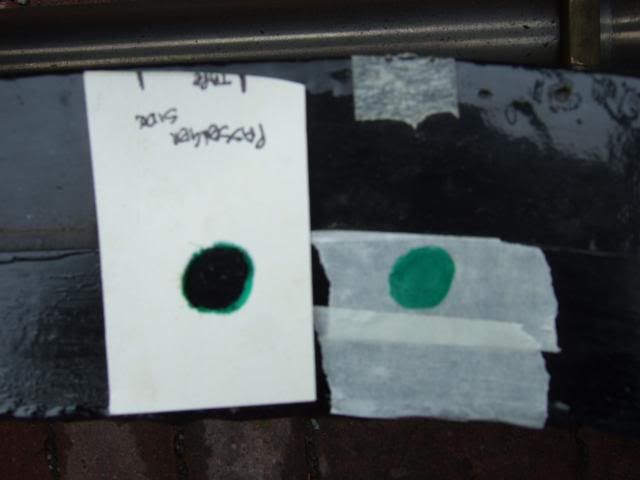

Then the underside got a light coating of etch primer...

As this primer is "weldable" I used it to highlight the pin holes in the driver's side floor.

This made the repair work a lot quick as I didn't have to keep holding the floor up to the light.

I then welded over all the holes & cleaned up the welds a bit.

I was careful to leave the welds "proud" of the surface as most of the holes were from "over enthusiastic" grinding.

Then the underside of the driver's floor was primed too...

Before I primed the "top" sides I wanted to mark up & trim the sides nearest the hand brake panel.

I'd already started this at one end of the driver's floor to match the curved frame...

But the passenger side was untouched (note primer marking some more pin holes to fix)...

Thankfully my jigsaw behaved itself this time & trimming the edges was much easier...

Given the fact I had a few "off cut" from the floors, I decided to add some metal to the driver's side.

I'd already welded in an extra bit of box section to the frame support the floor, as it didn't reach the frame at the back.

But I figured a couple of "extension" pieces would make the bonding / fibre glassing of the floor / body / etc. easier.

So after a bit of cutting and welding, I had this...

After I had finished welding the final pin holes in the passenger floor the "top" sides could be done.

I will use body filler over the welds on the inside edges to tidy them up before fitting the seats, but I've left this for now.

My eldest daughter offered to help, so she was roped into sanding one floor while I did the other...

She then sprayed the primer on, until it started running out & I had to squeeze the last bit out of the can...

Once I have done a final test fit of the frame, floors, seats & body shell, I will weld part of the floors to the frame.

- - - - - - - - - - - - - - - - - - - - - -

To be continued...

Last edited by Paul L; 9th September 2019 at 09:06..

|

9th June 2013, 17:55

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Making Hay While the Sun Shines - Part 2

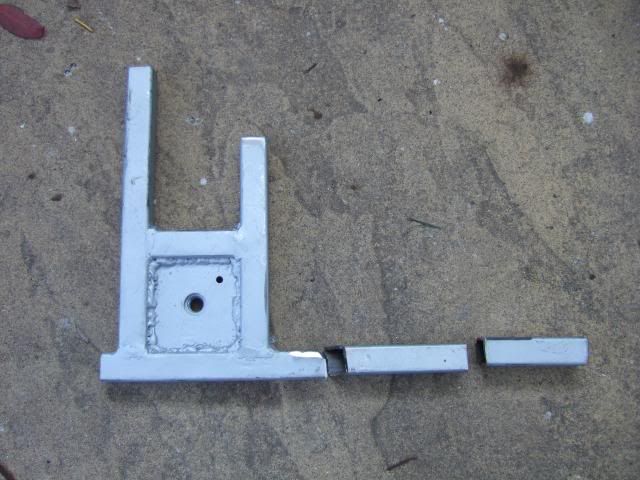

Side Seat Belt Mounting Point Brackets:

In order to finish the welding of these brackets I had to turn the frame over into different positions.

Starting with the frame "upside down", which allowed me to weld the right way up...

I also worked away with the frame on it side like this (obviously I did both sides)...

The welder started cutting out, so I had to add a bit of external air cooling from a fan to help...

But eventually it was all welded up & I could give the bare metal a coat of primer.

The driver's side bracket (note frame is still upside down while petrol tank brackets were being painted black)...

And passenger side...

When this was all dry I was able to give them a first coat of black paint.

I temporarily fitted the eye bolts & masked them off to keep paint out of the threads.

With a second coat of paint these brackets are now done.

I know these brackets are OTT & some of my welding could be neater / better.

However, the overall effect is something very solid, that will do the job & not fail under load.

When I was test fitting the seat belts for the rear cockpit brackets I could use the side one...

- - - - - - - - - - - - - - - - - - - - - -

Frame End Caps:

Another little job was following Viatron's suggestion to cap the open vertical frame rails...

Before:

I used an off cut from the floor pans to cut out two small metal sections...

By chance I had noticed something in one of the "holes" which dropped when I tried to take it out.

So I turned the whole frame upside down & poked around with a wooden skewer to remove 3 stones...

( The black everywhere is the waxoil I squirted inside the box section ages ago. )

Once I was happy there was nothing left inside, I welding the little sections into place...

After it had cooled now, it just needed a lick of black paint and it was job done...

- - - - - - - - - - - - - - - - - - - - - -

To be continued...

|

9th June 2013, 17:56

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Making Hay While the Sun Shines - Part 3

Rear Seat Belt Mounting Point Brackets:

Just before I bolted the petrol tank in place I had another think about the rear cockpit brackets.

I had found a couple of diagrams which provided some guidance for fitting racing harnesses...

Which ties in with previous replies on here to get the brackets as high as possible.

So I had another go at finding a good home for the bracket I had already built...

In order to test this properly, I put the floors in & got a seat & belts out.

This time I remembered to remove the seat bolts so the seat would be at the right height.

I used some masking take to hold the seat bolt spacers & a washer in place...

But this layout didn't really work as I had the same problem as before with the seat getting in the way.

However, I did spot that I could use the frame rail behind the main cockpit one like this...

This inset the eye bolt & seat belt attachments just enough to clear...

The racing harness sits nicely on the seat...

The belt sits nicely on my shoulder & there is room behind too...

But I couldn't start welding until the petrol tank was bolted it.

After that, I covered the tank with a dust sheet to protect it from any stray welding / grinding sparks.

I also cut the bracket & I will reuse the box section on the right as extra support...

I then cleaned up all the areas of the frame I was planning to weld to...

Then I could get on with clamping the bracket to the frame & starting to weld...

As before, this involved rotating the frame through 360 degrees to get at each edge...

Eventually the passenger side bracket was done, with the off cut box section now in place...

And this is the view from the rear & you will see I have capped the box section as before...

Then it was "simply" a case of doing the whole thing again for the drivers side.

And this is what that the driver's side looked like after I had got around to painting it...

Overall the two brackets now sit like this...

Again, I know this is a seriously OTT solution, but they will do the job for me.

- - - - - - - - - - - - - - - - - - - - - -

To be continued...

|

9th June 2013, 17:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Making Hay While the Sun Shines - Part 4

Spitfire Rear Arches & Floors:

I needed to move this section into my garden workshop, but first I wanted to lighten it a bit.

So after a sustained assault with a number of cutting discs, I went from this...

To this...

Which meant I could carry it through the house unaided (just as well as my wife was out).

So the garden picked up another strange ornament...

But I could then shift the Cordite bulkhead frame work over to the side of the body shell...

I then had an an epic sweeping up session to ensure there were no sharp metal fragments left.

The end result being I can give my wife back her parking space after almost 3 months...

There is still a bit of cutting to do before the rear arches can be fitted around the frame.

But that will be a series of jobs for next week.

- - - - - - - - - - - - - - - - - - - - - -

Confession - No.1:

After test fitting the seat, I went to put the seat bolts back in place & found one spacer missing.

It is bad enough when you drop something and can't find it on the garage floor.

But this was in the middle of the lawn and it was absolutely nowhere to be seen.

So at the end of the day I had to rake the whole area in a desperate bid to find it...

Despite all this work, there was still no sign of it, so I checked the path at the side of the grass.

In amongst my rubbish pile was a bit of "old" masking tape with the spacer stuck in the middle.

At least it is one less gardening chore to do.

- - - - - - - - - - - - - - - - - - - - - -

Confession - No.2:

Tracksuit bottoms are never going to offer much protection against molten welding splatter.

These are the holes burnt straight through the inside lining...

I'll spare you the photo of the corresponding burns in my skin to the side of my left knee.

- - - - - - - - - - - - - - - - - - - - - -

Right that is it, fair play if you have made it all the way to the end of this series of posts.

I will try to stick to my usual approach of little and often which is easier all round.

So until next time, take care, Paul.

|

9th June 2013, 18:40

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Great work, your seat belt upper mounts are in a much more suitable place now.

Don't lose heart, just keep plugging away and you'll get there in the end Paul. I checked my donor's V5 today and found that I collected it on 25th March 2011. That's twenty six months ago and I'm still not quite finished. My original timescale was to complete it in nine months...

|

15th June 2013, 08:43

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mister Towed - Seeing your car in silver is a true inspiration for the keep chipping away at it approach.

In terms of time lines, I am going to start running two separate ones from now on...

- My Cordite deposit & Spitfire donor date back to April 2012, so 14 months, or so, ago.

- But the final kit parts didn't arrive until March 2013, which is really just 3 months ago.

Jokes aside, the floor were such a key part of the building jigsaw, lots of work couldn't start without them.

I can honestly say I have absolutely no idea how long I will need to finish this project.

I made great strides when time & weather lined up for me last week.

But this week had been poor weather & lots of other things going on.

With a bit of luck I will get a few small jobs done this weekend.

Cheers, Paul.

|

15th June 2013, 09:38

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Glad you find my progress inspiring Paul.

With mine it's been the endless tinkering and learning new skills that swallowed up the time - I'm now 26 months into my project - but the result is the car I'd always promised myself.

Keep plugging away and the finishing post will accelerate towards you before you realise what you've achieved. Once finished, you'll have a car you can be truly proud of. One that, when someone says 'Wow! What's that?' you can reply 'Oh, just something I built.'  |

15th June 2013, 15:01

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Flaming June?

I guess it was just too much to ask for the weather to string a couple of dry weeks together.

This is what my framework development workshop looks like at the moment...

And the photo doesn't really do justice to the noise that the rain lashing down is making.

So I'm guessing no work outside for me today.  Father's Day:

Father's Day:

I might push my luck a little tomorrow to arrange a family Cordite frame lifting session in the morning.

I've found the cardboard templates I made to locate the seat belt holes either side of the hand brake.

But I need to carry the frame through the house onto the front drive to mark it up when on the chassis.

If I just stick masking tape on the frame, I can mark it up & carry it straight back into the garden.

That way if the sun every returns I can drill the holes in the frame one evening after work.

As I realised that these holes are the key to me aligning the Spitfire rear wheel aches section.

( Holes in the hand brake panel line up with the holes in the Cordite frame / Spitfire chassis. )

Until then, take care, Paul.  Replies

Mr T

Replies

Mr T - The more build threads I read, the more reasonable your build timeline seems.

As you often say, this is our hobby, not a full time job & we have other things going on in our lives too.

|

16th June 2013, 11:53

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Father's Day:

As explained yesterday, I knew I'd only get a chance to do one simple job today.

With my wife's help I did get the frame through the house to the front drive.

I then removed the Cordite body which is sitting over the Spitfire chassis & fitted the frame.

Using my cardboard template I was able to mark the position of the seat belt mounts...

( Not easy to see a black frame sitting on a black chassis.  )

While I was at it, I also marked up roughly where I will bolt the frame to the chassis...

( The holes for the seat belts will not really be used to keep the frame in place. )

I want to keep the rear frame mounting bolts inside the cockpit area.

Also the extreme ends of the frame do not sit on the chassis (& never have)...

I will just make sure there is a big bonding blob underneath this area when I am fitting it.

My poor wife then had to help me bring the frame back through the house into the garden.

I packed up everything at the front of the house & then had to mow the lawn.

This allowed me to put the frame back on the grass in a different place & re-cover it.

( As I am trying desperately hard not to kill the lawn while working on the frame. )

Right, I have got to go, cheers, Paul.

|

16th June 2013, 12:32

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, every job done is another step mate.

I was planning to use fathers day as a freebie to sit at the dining room table and strip my dcoe 45 ready for the major parts to go off for vapour blasting and ultrasonic cleaning as i solo babysat the grandaughter yesterday so couldnt get up the workshop.

No such luck! So far today, mown front lawn, mown rear lawns, cooked mushroom stroganof for dinner tonight, done laundry reay for london tomorrow, been shopping, removed bike and bike rack from the mondeo...and i still haven't finished......

|

16th June 2013, 14:04

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

A Ribble builder's work is never done.

|

16th June 2013, 16:27

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

But then i did get a good t-shirt for fathers day:

"Paddle faster, I hear banjos......"

|

23rd June 2013, 17:36

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Slow Progress:

Well another week slips by and life & the weather have conspired against me.

Still I have managed to get a few minutes to play and this is what I did...

I made my first attempt to join the Spitfire rear aches to the Cordite frame...

I was just planning to mark up where I needed to cut, but I ran into a problem straight away.

The the top of the arch above the prop. shaft hits the bottom of the petrol tank...

( Not a great photo I know)

But this was nothing a quick trim with the angle grinder couldn't fix...

I ended up using my trolley jack to help me to position the Spitfire section...

And eventually I was in a position to roughly mark out where the Cordite frame will be...

Then it was back to the angle grinder to do some more cutting...

I needed the cut out to be approx. 2 inches deep...

That way the holes in the hand brake panel will line up with the holes in the frame.

( See previous post where I marked up the position of the chassis holes on the frame. )

This was repeated on the driver's side and I was left with 2 cut outs...

But at this point I had to call it a day and I will try another test fitting during the week.

( Weather permitting.  )

Once I know everything fits, I may weld some metal back in to "box" this section.

Different Battery Charging:

In an effort to get my "normal" car back on the road I have been charging my flat battery.

Given it is a 2L diesel, it does make the Spitfire battery look small by comparison...

So until next time, take care, Paul.  Replies:

Viatron & Oxford

Replies:

Viatron & Oxford - Cheers chaps.

I have a lot of chores at the moment as we have friends coming around next weekend for a BBQ.

So for a change I have been doing some gardening in the garden, instead of car building.

|

23rd June 2013, 18:31

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Gardening in the garden.....madness!

|

30th June 2013, 06:36

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

No Real Progress:

We have some old friends coming over for a BBQ this afternoon.

So most of this week has been spent get ready for that.

And I started by giving myself more storage space in the summer house.

With a fully charged battery back in my car, it was off to IKEA for more shelving...

This allowed me to extend an existing set of shelves & put another wider set at 90 degrees to it.

This lets me stack the storage boxes higher as there were falling in on top of each other...

The summer house now has all the parts, tools & other stuff that was in the utility room.

So a few brownie points for me for clearing some space there.

I also transferred the last of the "off cuts" from the Spitfire body to behind the summer house...

These were in various piles on the front drive, so that is now tidier too.

Finally, I shifted the frame off the grass & tucked that down the side of the summer house...

( This will be back on the grass & under a cover by the end of the day.)

It would have been nice to test fit the rear arch section to the frame after making the cut outs.

But it looks like that will have to wait until during the week at the earliest now.

Until then, take care, Paul.  Replies:

Viatron

Replies:

Viatron - Hopefully I will get back to "normal" car building in the garden next week.

|

30th June 2013, 07:51

|

|

Senior Member

|

|

Join Date: Dec 2011

Posts: 656

|

|

Off cuts! You could build a 'Se7en' Shell out of that  |

6th July 2013, 11:50

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Major Home News:

I have been a little bit distracted from my build over the last few weeks.

But I am leaving my job at the end of July after 18 years with the same company.

This might sound a little rash, given that I don't have a new job to go to (yet).

But the time is right to make this break and see where life takes me next.

However, I've built up a financial "cushion" over the years, so my family is protected.

So jumping is considerably easier to do when there is a safety net in place.

Impact On Build:

This may actually turn out to be a good thing for my Cordite project.

As I have my wife's support / blessing to take a short "sabbatical" between jobs.

So I should be able to spend some of August working "full time" on the build.  Next Steps:

Next Steps:

There is a lot of work "stuff" to sort out in the next few weeks which will take some time.

But I do want to make use of the sunshine to mate the rear arches to the frame.

Until then, take care, Paul.

Replies:

AndyP57 - Some of this metal is bound to find its way back into the car somewhere.

|

|

Currently Active Users Viewing This Thread: 13 (0 members and 13 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 04:01.

|