Yesterday was a major Spring (Winter?) clean before we put the Christmas tree up.

I was also forced to spend time up on on Santa's sleigh landing stop (see below).

Then most of today I have felt rubbish, but eventually I got outside just before sundown...

Engine Re-Start - Attempt #2:

Before I had another go, I re-read WCA's "First fire of the build" thread

here.

I also did a quick Google search & found another great thread with a helpful photo

here (last post).

And these highlighted the simple schoolboy error I made during my first starting attempt.

I thought the "earth" lead bolted to the engine was

providing the earthing point for the loom.

Where as, it actually needs to be connected to earth itself & this was previously where it joined the body.

So making sure the loom was fully connected to the engine was a complete waste of time.

I knew I needed new earth points on the frame for my lights, etc. but missed this completely, oops.

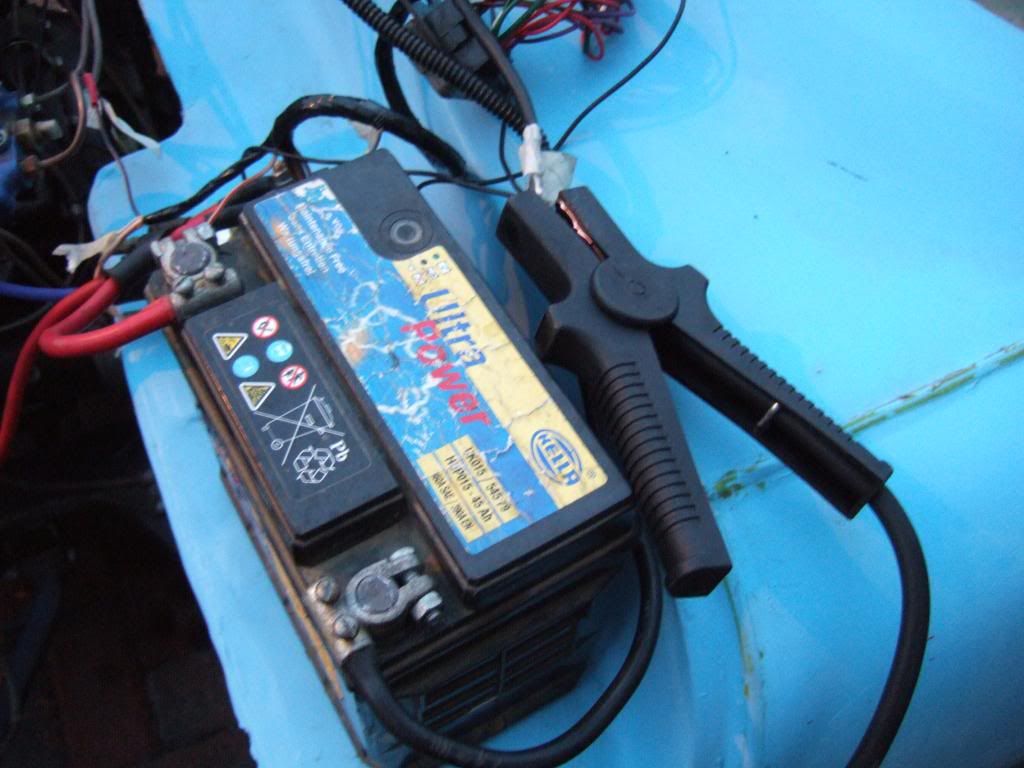

But before testing my earthing theory, I dug out some of the surplus wires I had removed from my loom.

I then wired both the starter solenoid & coil mounting points back to the main battery earth wires.

( This was just a temporary measure for the engine start & I will wire it all up properly later on. )

My final bit of simple trouble shooting before connecting everything back up was with the starter motor.

Using jump leads, I connected the "-ve" battery terminal to the frame & touched "+ve" lead to starter.

This got the starter motor turning over, so that was one possible problem removed from the equation.

So I plugged my wiring loom back in again to just the main connections needed (gearbox wires not required).

Along with the wiring diagram I also printed off a copy of the original solenoid & coil wiring to double check.

I then created a new earth point with a jump lead from the wiring loom at one end to the chassis at the other.

( Excuse the poor photos as it was starting to get dark. )

Turned the key the first turn, nothing happened at all and my heart sank.

Then I quickly spotted that I had forgotten to connect the loom plug back to the ignition switch.

So take #2 of the first turn of the key and this time the ignition light came on as before, so far, so good...

But unlike last time, there were definite signs of life coming from the engine at the next turn of the key.

I hadn't re-fitted the throttle or choke cables, so needed to operated their levers on the carb. by hand.

( Sorry couldn't operate choke & throttle and take the photo.

)

It took a few attempts to get the petrol in, but eventually...

[Dr Frankenstein]

"IT IS ALIVE! . . . . ALIVE!" [/Dr Frankenstein]

You have no idea how happy I was to hear the engine running again.

Obviously it was working before I dis-connected everything, so I'm just glad I hadn't messed it up.

I left it running for a while before switching it off, but thankfully it kept starting each time I tried it again.

So whilst it may not look like much, this is a functioning wiring arrangement.

Santa's Sleigh Landing Area (or Domestic Appliances #3)

Santa's Sleigh Landing Area (or Domestic Appliances #3)

It rained so hard & was so windy on Friday night that water managed to get into our en-suite in the loft.

It had come through the extractor fan, after travelling through over 8 feet of hose!

So I spent Saturday afternoon climbing out the skylight, up the front roof & onto the rear dormer.

Here is one of the views...

Turns out the builders decided to located the external vent next to the roof edge and gutter.

I had to remove the gutter, tape up the top half of the vent & refit everything.

Hopefully this will keep the rain out (fingers crossed).

The only good news is that was a few extra car building brownie points in the bag.

Until next time, take care, Paul.

Mister Towed

Mister Towed - I'll need to sort out my insurance with 'A Plan'

before I blow the car & street up!