|

|

| Vintage and Classic Roadster Kit Car Builds For Vintage and Classic era kit cars. Post your build reports, problems and progress here |

10th October 2018, 04:48

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Quote:

Originally Posted by Jaguartvr

I find a 1mm thick cutting disc in an angle grinder is the quickest and easiest way of cutting thicker steel. The 1mm discs cut very quickly but also wear out very quickly so buy in bulk and invest in a quick change angle grinder nut.

|

I generally use mine for straight cuts, but find the jigsaw's easier for curves.

Yesterday I marked out and cut the second mounting plate which will be on the engine bay side of the bulkhead, creating a metal sandwich.

I then cut the necessary slots in the rear deck and rivetted the two escutcheons in place. The edges of both the slot and the flange needed a little dressing, which I did after taking this.

No. 2 son works on Tuesdays, so I couldn't press on with the pedal box mounting as this will have to be done with the body off. Maybe today?

Regards, Mick |

11th October 2018, 04:53

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Radius Arm Mountings

Radius Arm Mountings

Yesterday's task was to mark the locations of the forward radius arm mountings on the underside of the body. Like the pedal box, they will have substantial 3mm steel sandwich plates to ensure a sturdy mounting. Ever cautious, I decided to check the wheelbase dimension as I've noticed, when pushing the beast in and out of the cave, that the back wheels move a little fore and aft. The book of words gave the dimension as 83" so I fabricated a demon measuring stick with 1¾" wire ovals protruding at the required spacing. The gap was approximately ¼" too great so I used a ratchet strap to pull things into line. I could then support the mounting plate and attached radius arm gently against the underside with the scissor jack and mark its outline. Repeat for other side.

My son wandered down the garden at this stage to ask if I wanted to take the body off but, once again, it was simply too hot to continue so I packed up.

Regards, Mick

|

18th October 2018, 07:00

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Progress of sorts.

Progress of sorts.

Tuesday and yesterday I applied myself to fitting the beefier M10 Range Rover wheel studs to the front hubs. I'd fitted the more straightforward rear ones some time ago and had been feebly putting off this task.

Starting with the offside one (nearer to the workbench), I clamped the disc in the vice and tried to get a socket over the head of the first of the four bolts securing it to the hub. The shape of the casting prevented a very secure location so I substituted a ring spanner tapped on with a hammer and bashed its end to start things off. After a few goes it was proud enough to get the socket on and gently undo it. This worked fine for another two of the bolts but the fourth stubbornly resisted, even after lots of dismantling fluid and heat. I decided to leave it in soak overnight and try again mañana.

Yesterday morning, no change, even after lots of heat. I bit the bullet and used a 4mm HSS bit and my smallest cold chisel to relieve the offending part of the casting. The last bolt then came away easily. Tapping the hub from the disc and drawing the new studs through their holes with a wheel over it, using the new nuts, was simple, as was re-assembly. The near side hub, although identical as far as I could see, proved simplicity itself, the socket being fine on all four bolts. Weird.

Next job was to run my MGF wheels down to the tyre place, agree on 175 65 15s and leave them there for collection today.

Body removal assistance was was once again unavailable  so I decided to paint my pedal box sandwich plates. My new litre of acetone had arrived earlier so a quick degrease and a few passes with a rattle can had this done.. The paint is matt black but the photo' has lied, showing it as grey. More weirdness. so I decided to paint my pedal box sandwich plates. My new litre of acetone had arrived earlier so a quick degrease and a few passes with a rattle can had this done.. The paint is matt black but the photo' has lied, showing it as grey. More weirdness.

That was it for the day.

Regards, Mick

|

19th October 2018, 05:44

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

I broke the habit of a lifetime

I broke the habit of a lifetime

and bought five new tyres for a project  . The anticipated 'phone call came late morning and I whizzed down to the tyre place in the Micra, armed with a picture of a Monaco. The guy on the desk had asked me what car my tyres were for, and I'd replied that he wouldn't know if I told him. Anyway, both he and his boss (top bloke, he'd left ProTyre to set up on his own, taking most of their staff with him) asked me to bring it along when it's done. . The anticipated 'phone call came late morning and I whizzed down to the tyre place in the Micra, armed with a picture of a Monaco. The guy on the desk had asked me what car my tyres were for, and I'd replied that he wouldn't know if I told him. Anyway, both he and his boss (top bloke, he'd left ProTyre to set up on his own, taking most of their staff with him) asked me to bring it along when it's done.

On return, as help was available, I pressed on with the pedal box after plonking the body on the grass. I'd made a cardboard template of the mounting plate showing where the pedals hung and offered it up in the engine bay to mark the first of the mounting holes, making sure that the steering column hole was between the pedal positions. Once the first hole was drilled, it was a simple matter to bolt the plate into position and drill though it for the other five. The two large holes were already cut when I got the project, as was the steering column one, which luckily turned out to be spot on. I'll fill the biggies before final assembly.

The day was marching on by now, and my son was going to work, so I enlisted his aid and replaced the body. All that was left was to fit my MGF wheels  . .

The back ones may need slim spacers, time will tell, and the fronts may necessitate limiting the lock with hose clips. Again, the proof of the pudding....

I have to say that I'm thrilled with the way she looks with her new boots, much more in keeping with the overall look than the 13" ones!

Regards, Mick

|

19th October 2018, 07:29

|

|

Senior Member

|

|

Join Date: Dec 2011

Location: Devon

Posts: 550

|

|

Those wheels have certainly changed the look of the car which is really taking shape now. Keep plugging away at it.

|

19th October 2018, 10:57

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Looking good, Mick. I always enjoy your early morning updates  |

19th October 2018, 15:05

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Very nice with the larger diameter tires & wheels.

|

21st October 2018, 06:23

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Friday's Progress

Friday's Progress

Help was available early, so off with the body which I rolled over to drill the radius arm bracket holes. The outlines I'd marked more or less blind proved to accurately match the mounting plate profile on both sides, so I was happy to proceed in the knowledge that rear wheel alignment would be within manufacturer's tolerances.

Once I'd drilled the eight 6mm holes I turned her right side up and made stiff card templates of the disposition of the cockpit side holes to use marking out the sandwich plates. Help was then leaving so we replaced the body.

I then turned my attention to the silencer, which I'd earlier offered up to the long under body pipe to find that the tail pipe stuck out a good foot. Its mounting bracket was also exactly under where the floor meets the back body, so I decided to cut the long pipe back as far as possible. The required cut's location was right under the rear frame crossmember: I briefly considered removing the long pipe but instead plumped for taking the side handle off my angle grinder, starting the cut with a worn down disc, and finishing it with a new one. After tidying the edges with files I replaced the silencer. Some six or seven inches will need to come off the tail pipe which I'll do on the bench to ensure a tidy cut. It's also a little too low so my centre hanger will need re-thinking.

That was it for the day.

Regards, Mick

|

27th October 2018, 07:44

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Bits and Pieces.

Bits and Pieces.

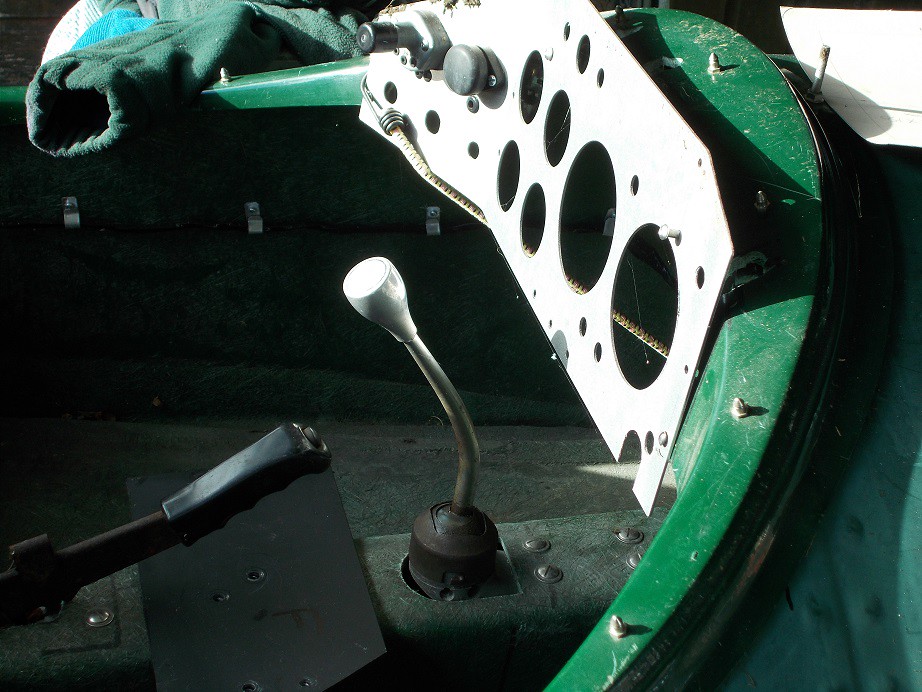

Finishing off my handbrake linkage was a task I'd been putting off, as even the original Spitfire installation when working perfectly was little more than marginal. I re-thought the mounting for the multiplier lever using ¾" box and ½" rod. Careful drilling, sawing, filing, bolting and cotter pinning resulted in this masterpiece, which will be bolted through the inside of the body tunnel.

My next job was to bend the top of the gear stick back a couple of inches as my knuckles hit the dash in reverse, 1st and 3rd. After removal, I clamped the base firmly in the vice, slipped a piece of narrow steel tube over the top to protect the thread, then an 18" length of ¾" box. I was surprised just how easily it bent. Reassembly confirmed my knuckles were now safe.

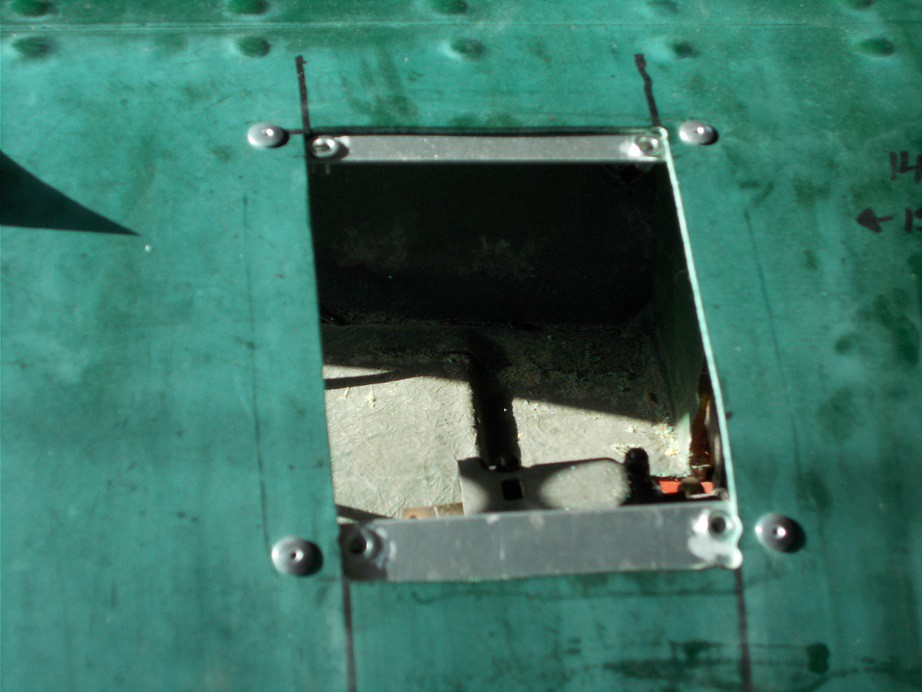

Next job was to make an easily removable panel for the master cylinder access hole. I looked at Dzus fasteners but was put off by the price. I hit on the idea of using Rivnuts, some of which I had left over from my A352 build. I cut a couple of lengths of 3mm x 25mm aluminium flat, fitted the Rivnuts, then drilled and rivetted them into position.

Careful measuring, cutting and drilling had the cover plate fabricated. I'll stick some rubber strip to the back of the edges sometime to ensure wind and waterproofing.

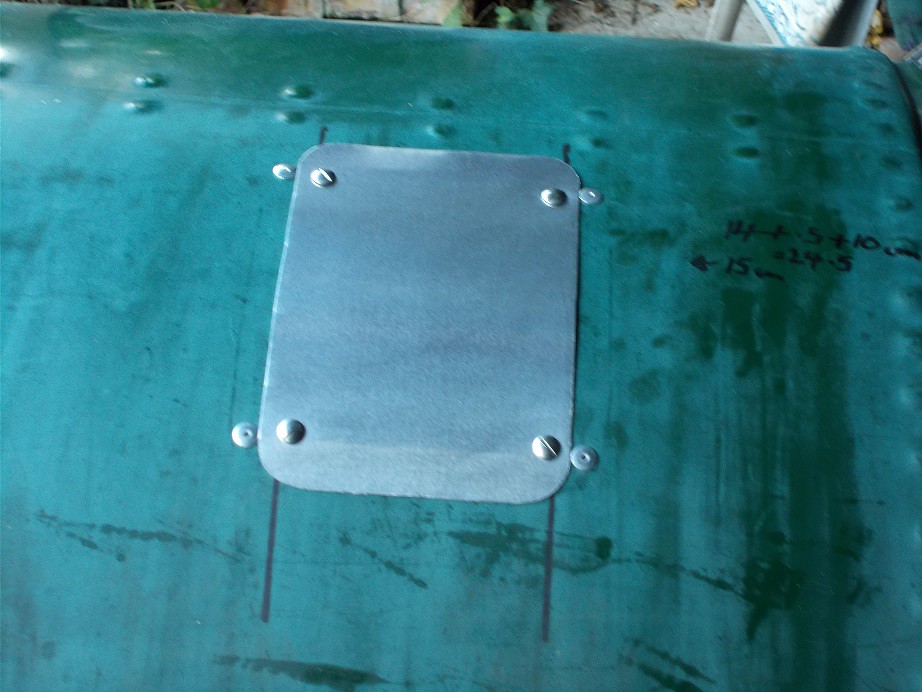

While the Machine Mart tin snips were out I decided to make one of the plates to tidy up the massive suspension holes cut in the body by a previous builder. Cardboard Assisted Design resulted in this which I'll rivet on with its unmade as yet siblings after painting.

Regards, Mick

|

27th October 2018, 09:23

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Coming along very nicely, Mick. Love both the term Cardboard Assisted Design and the low-tech nature of it.

|

27th October 2018, 19:30

|

|

Senior Member

|

|

Join Date: May 2009

Location: POOLE , DORSET

Posts: 2,200

|

|

slotted raised countersunk fixings look cool too ....I try to use slotted fixings in visual areas as opposed to posi screws etc . when I can ...just one of my things ...

|

2nd November 2018, 06:39

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Feeling Eclipsed!

Feeling Eclipsed!

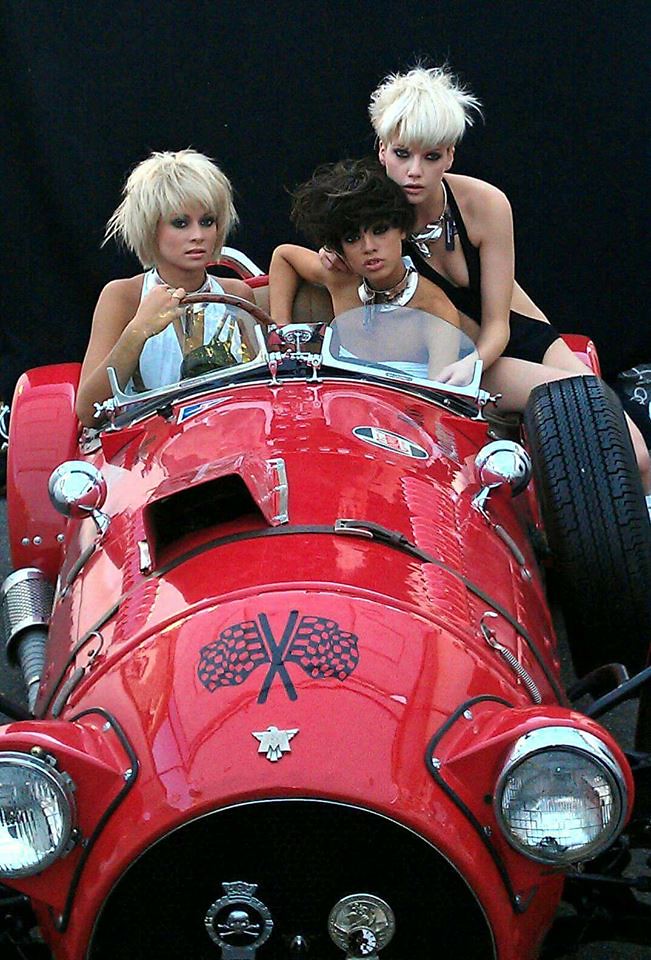

I belong to a Facebook group titled 'Homebuilt Cars, from scratch or kits', and am in awe of what some members are achieving across the pond, unhindered by SVA. Today I came across this video which features a Stateside Monaco of sorts.

Brilliant!

Regards, Mick

|

2nd November 2018, 06:55

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Utterly bonkers. I love it.

|

2nd November 2018, 06:57

|

|

Senior Member

|

|

Join Date: Jan 2014

Location: Egham, Surrey

Posts: 1,780

|

|

Quote:

Originally Posted by lancelot link

slotted raised countersunk fixings look cool too ....I try to use slotted fixings in visual areas as opposed to posi screws etc . when I can ...just one of my things ...

|

Just make sure all the slot heads are pointing in the same direction. Stepfather rebuilt an Austin A40 Devon pickup, the rear deck was wood and every slot head screw was in alignment, really was a finishing detail and it was amazing how many people noticed it. |

2nd November 2018, 10:51

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Fastidious fixings

|

6th November 2018, 07:15

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Some Progress

Some Progress

Progress has been slow over the last couple of weeks whilst I've concentrated on the back brakes. To make absolutely sure that my demon handbrake effort multiplier is mounted optimally, I realised that the rest of the linkage back to the shoes would need to be in place. I checked my mound of parts to find that I had no backplate levers, so these I ordered. I examined the four drums and decided they were too worn to use in that condition. When building the A352 I'd come to the same conclusion and had them skimmed and faced locally. I just was about to march down to the engineering workshop with them when I thought to check the price of new ones, which was considerably less than I'd paid for machining. These I ordered. Once they'd arrived I assembled my bits, jacked up the back end and removed the wheels, only to find no adjusters  . More ordering, more delay. . More ordering, more delay.

In the meantime, having noticed some de-lamination in the edges of my plywood 'floors', I purchased some superior marine ply (buy cheap, pay twice!), removed the existing which made handy templates, and cut and fitted the new ones. This time I corrected a previous omission and screwed on a vertical back for the luggage area behind the seats. Thinking that this might drum, I made a pair of angled brackets to prevent this. Excuse rubbish picture.

Yesterday, at long last, all the new brake bits were to hand, and were successfully fitted.

Another Spitfire based Monaco had come up for sale in the Moss FB group, so I gave the vendor a ring for a chat about a possible viewing for ideas, as it was dismantled after being on the road. In particular, I was interested in the windscreen from which to take a paper patten as my efforts were rubbish. He said he'd have a look for it and get back to me. However, in the interim, I'd scrolled back through this thread and decided to go down this route....

Moss (bizarrely) in Bristol only had one in stock, and this I received yesterday. I'm hoping that I can get the second at the Classic Car Show this Friday, especially if there's a 'show deal' available  . .

Regards, Mick

|

6th November 2018, 08:21

|

|

Senior Member

|

|

Join Date: Jan 2014

Location: Egham, Surrey

Posts: 1,780

|

|

If you give the edges of the plywood a coat of grp resin it will stop any water creeping in later on. In fact, it is probably worth giving all the plywood a coat.

|

8th November 2018, 07:18

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Small Steps

Small Steps

The weather hasn't been helping, but on Tuesday I trial-fitted the radiator by standing it on a wooden block, fitting the top and bottom hoses, and fabricating brackets to locate it to the U shaped support which bolts to the frame. The upright arms of this provide attachment points for the engine bay splash guards on a Spitfire, not needed on the open-wheeler Monaco, so I'll cut off the redundant portions. Not really worth a picture, I may post one once everything's in place.

Looking at the weather forecast I realised that plonking the body on the grass wasn't going to happen so I set to fitting the pedal box with the body on the chassis. The footwell side had good access through my master cylinder servicing hole, but the engine bay side was severely restricted by the rear SU which had worn holes in my forearm by the time I'd finished. This was a very fiddly job as the ¼" UNF bolts had to be the exact correct length so that they didn't interfere with the pedals. The solid part of their shanks also needed the die running down them to get them fully home in the captive nuts. After a couple of hours trial and success all was finally in place. Excuse yet another crap photo'.

Filling that lower hole will definitely have to wait until the body's off.

Regards, Mick

|

9th November 2018, 06:52

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

A Slow Day

A Slow Day

Yesterday I fettled the top radiator supports a little more, and trial fitted them: all good. The bottom supports will need to be more substantial, but a search of my metal heap failed to locate anything suitable - the 3mm steel falling into the 'overkill' bracket. Ebay will doubtless come to the rescue.

I turned my attention to the aeroscreen supports, which don't seem man enough for the job. The two holes through which each is mounted to the body were between 4 & 5mm diameter (see the 'Bananarama' picture above) and at right angles to the stresses they're supposed to resist. I ran my 5mm tap through them which removed only the chrome plating. More Ebaying will provide A2 countersunk screws which, when fitted, will perform as studs. Small pedestals, again as in the picture, will be needed for the outer mountings so I trial made one from 2" of ¾" box with 45° ends. The light was fading by then so I called it a day.

The one really bright spot was the nice man bringing this  . I hope its application will be soon! . I hope its application will be soon!

Regards, Mick

|

|

Currently Active Users Viewing This Thread: 10 (0 members and 10 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 08:04.

|