|

|

| Marlin Sportster, Cabrio, Berlinetta and Roadster builds Enthused or Confused about your vintage Marlin build? Ask away here or show off your build. |

21st June 2008, 21:56

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by MartinClan

I have the part number of the Marlin supplied ball joints. They were Quinten Hazel QSJ10605 or QSJ1060S (Can't read my own writing...)

Robin

|

Thanks, Robin.

QSJ1060S gets a few hits on Google and it looks like they are Metro/MGF ball joints!

I might try and make a 'tappered cylindrical shim' out of 0.5mm copper sheet as I am concerned the downward forces from the hub will loosen the joint?

Any thoughts?

Peter |

22nd June 2008, 18:03

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,892

|

|

Quote:

Originally Posted by peterux

I might try and make a 'tappered cylindrical shim' out of 0.5mm copper sheet as I am concerned the downward forces from the hub will loosen the joint?

Any thoughts?

Peter

|

Hmm. I suspect the problem is that the BMW taper is almost the same as the Metro one but the tolerances mean that sometimes there is a problem. What we really need is for someone to measure an original BMW one.

I shall be taking my suspension to bits again soon as I am hopefully going to get some replacement wishbones. I will measure the taper on the ball joints that I have while I am at it (assuming I can get them out of the wishbones!)

Robin |

22nd June 2008, 18:05

|

|

Senior Member

Enthusiast

|

|

Join Date: Feb 2005

Location: Hampshire

Posts: 2,497

|

|

It's a shame your not closer, my impact air tool makes light work of removing ball joints!

You can get a socket bit that fits over them in halfords (about £12) which you can combine with a breaker bar  |

24th June 2008, 20:32

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by MartinClan

Hmm. I suspect the problem is that the BMW taper is almost the same as the Metro one but the tolerances mean that sometimes there is a problem. What we really need is for someone to measure an original BMW one.

Robin

|

Well, I found a BMW e30 outer suspension ball joint on eBay so couldn't resist ordering it to measure it up.

A quick measure up with my trusty micrometer confirmed Robin's hunch.

The BMW replacement ball joint taper measures 16.50mm at the widest point and 14.50mm at the narrow end.

That means the metro taper shaft is too narrow and will only touch at one place allowing the shaft to pull through more than the BMW engineers planned for.

Taking another look at my build manual (LOL) I can now see a version of the wishbone with these press fit balljoints.

Apart from cost, I wonder what caused Marlin to change the design to the screw-in metro joints? |

25th June 2008, 07:16

|

|

Senior Member

Enthusiast

|

|

Join Date: Feb 2005

Location: Hampshire

Posts: 2,497

|

|

Quote:

Originally Posted by peterux

Taking another look at my build manual (LOL) I can now see a version of the wishbone with these press fit balljoints.

Apart from cost, I wonder what caused Marlin to change the design to the screw-in metro joints?

|

Makes servicing easier perhaps? You need press to get the push in ones out. |

25th June 2008, 22:00

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by peterux

I might try and make a 'tappered cylindrical shim' out of 0.5mm copper sheet as I am concerned the downward forces from the hub will loosen the joint?

Any thoughts?

Peter

|

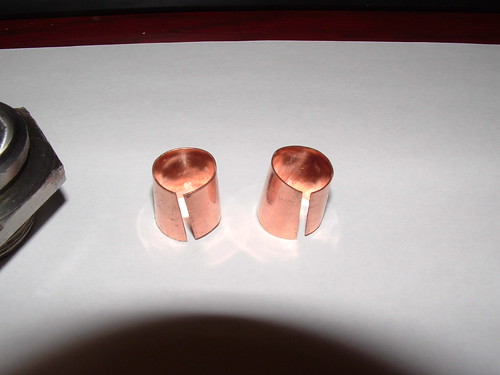

Here is my first attempt at making some shims....

The copper will compress slightly filling the slightly different tapper angles, but I am wondering if the copper will be too soft and the balljoints work loose after time?

I guess i'll give them a try..........

Peter

Last edited by peterux; 25th June 2008 at 22:01..

Reason: typo

|

26th June 2008, 09:04

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,892

|

|

Quote:

Originally Posted by peterux

Here is my first attempt at making some shims....

Peter

|

Hi Peter

Are you sure that the angle of the taper is different and not just the length of the taper? If the angle is different I think we should ask Marlin to comment.

I think your copper shim should work OK (after all they use it for head gaskets) but I think you will have to be careful that it doesn't show - I am sure the MOT man wouldn't be happy...

It will be interesting to see what it looks like when it has all been clamped up and then undone again. If the tapers are different presumably the copper will be more squashed at one end than the other. Should be possible to measure with a micrometer I guess.

Cheers

Robin |

26th June 2008, 18:37

|

|

Senior Member

Enthusiast

|

|

Join Date: Jan 2007

Posts: 932

|

|

Lower Ball Joint

Lower Ball Joint

Peter

I am sorry to say this, but how do you guys justify taking an experimental approach to a highly safety critical item such as a lower steering ball joint. If this fails you could injure or kill yourselves, or worse still, others.

This item should not be experimented with. If there is a problem, and you seem certain there is , then go back to Marlin and request they resolve the issue safely.

Regards

Mike

|

26th June 2008, 19:51

|

|

Senior Member

Enthusiast

|

|

Join Date: Dec 2005

Posts: 203

|

|

From what i see the Marlin supplied balljoints are the correct size. The issue seems to be with the metro balljoints some guys are buying because they are cheaper. I would be happier fitting the Marlin supplied joint all be it a lot more expensive rather than attempting to make the metro joints fit.

Stuart

|

26th June 2008, 19:58

|

|

Senior Member

Enthusiast

|

|

Join Date: Feb 2005

Location: Hampshire

Posts: 2,497

|

|

I've not had any problems with the metro replacement I got. I'll if I still have the one broken one and compare it to the new ones I got.

|

26th June 2008, 20:17

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,892

|

|

Quote:

Originally Posted by Stuart

From what i see the Marlin supplied balljoints are the correct size. The issue seems to be with the metro balljoints some guys are buying because they are cheaper. I would be happier fitting the Marlin supplied joint all be it a lot more expensive rather than attempting to make the metro joints fit.

Stuart

|

The Marlin supplied joints are Metro ones! Mine still had the Quinten Hazel packaging and we Googled the part number. They are also used on the MGF.

I can only guess that some of the cheaper pattern ones are made to dodgy tolerances and its probably best to stick to those from QH.

Robin |

27th June 2008, 21:29

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by Mike

Peter

I am sorry to say this, but how do you guys justify taking an experimental approach to a highly safety critical item such as a lower steering ball joint. If this fails you could injure or kill yourselves, or worse still, others.

This item should not be experimented with. If there is a problem, and you seem certain there is , then go back to Marlin and request they resolve the issue safely.

Regards

Mike

|

Hi Mike,

welcome to the world of building a Marlin car! The whole exercise is a bit of an experiment and the purpose of posting here is to share issues, ideas and solutions. I originally posted the issue of the metro ball joints to alert other builders to the problem that I ran into. Whatever the reason for the problem, other builders can easily run into the same issue.(I did!)

I'm still working on the true root cause (Did I overtighten the ball joints?, Did I buy the wrong ball joints?, Were the ball joints I bought undersize?,Are Metro balljoints just the wrong size?etc etc)

Again, sharing my findings and possible causes will hopefully hone into the correct solution. Like you, when I first started, I assumed Marlin would sort every issue but unfortunately experience shows that raising any issues like this with Mark is either met with disbelief or discalimers that nobody else has ever had a problem so it must be something you are doing wrong.

I posted my potential solution, again to get some feedback. I am not recomending it to any other builders, but currently do not feel the copper shims will make it any less safe than already. The shims will be firmly trapped between the ball joint taper and the upright hole. But like I say, I'm still interested in any feedback or suggestions on why this may not be a suitable solution.

Currently, I feel that my balljoints are unsafe because they can move up the tappered hole and damage the ball housing. The balljoints at my MOT were clearly knackered and I was very pleased the MOT guy found it or I would never have noticed it.

br

Peter

|

27th June 2008, 21:54

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by MartinClan

Hi Peter

Are you sure that the angle of the taper is different and not just the length of the taper? If the angle is different I think we should ask Marlin to comment.

I think your copper shim should work OK (after all they use it for head gaskets) but I think you will have to be careful that it doesn't show - I am sure the MOT man wouldn't be happy...

It will be interesting to see what it looks like when it has all been clamped up and then undone again. If the tapers are different presumably the copper will be more squashed at one end than the other. Should be possible to measure with a micrometer I guess.

Cheers

Robin

|

Thanks, Robin,

you've spotted something obvious that I missed.

The length of the taper on the BMW joint is 20mm whereas on the Metro ball joint it is only 15mm long. So the taper angles may be the same?

And guess what, the depth of the BMW tappered hole is 19mm deep!

So if we assume the taper stops at the top of the tappered hole, the BMW upright is already starting to crush the rubber gater surrounding the ball joint.

If it moves up another 3mm it hits the top of the balljoint ball casing.

I wonder if there are different versions of the Metro ball joints??

Peter

|

30th June 2008, 08:55

|

|

Senior Member

Enthusiast

|

|

Join Date: Jan 2007

Posts: 932

|

|

[Hi Mike,

welcome to the world of building a Marlin car! The whole exercise is a bit of an experiment and the purpose of posting here is to share issues, ideas and solutions. I originally posted the issue of the metro ball joints to alert other builders to the problem that I ran into. Whatever the reason for the problem, other builders can easily run into the same issue.(I did!)

I'm still working on the true root cause (Did I overtighten the ball joints?, Did I buy the wrong ball joints?, Were the ball joints I bought undersize?,Are Metro balljoints just the wrong size?etc etc)

Again, sharing my findings and possible causes will hopefully hone into the correct solution. Like you, when I first started, I assumed Marlin would sort every issue but unfortunately experience shows that raising any issues like this with Mark is either met with disbelief or discalimers that nobody else has ever had a problem so it must be something you are doing wrong.

I posted my potential solution, again to get some feedback. I am not recomending it to any other builders, but currently do not feel the copper shims will make it any less safe than already. The shims will be firmly trapped between the ball joint taper and the upright hole. But like I say, I'm still interested in any feedback or suggestions on why this may not be a suitable solution.

Currently, I feel that my balljoints are unsafe because they can move up the tappered hole and damage the ball housing. The balljoints at my MOT were clearly knackered and I was very pleased the MOT guy found it or I would never have noticed it.

br

Peter]

Peter

I think this is a sad indictment of Marlin. I know exactly what you mean though. Before I bought my Cabrio I asked Terry if the kit was now fully "sorted out". She got quite stroppy and indignant that I could suggest it might not be. So I gave her the benefit of the doubt.

Having worked on it now for sometime, it is clear there are many areas where better attention to detail, and feedback from guys like yourself would have benefitted the design/quality of the finished car.

Some things you can (and should?) resolve yourself: others though, which are safety critical, should be taken up by Marlin and resolved immediately. Look at what happened to Patrick's car - that could easily have been so much worse..........

I had a similar issue with the steering extension shaft- I could not understand how it would fit?

It turned out Mark had changed the design which required a different UJ without telling me, or even Terry! They did supply me with the new UJ after some persuassion.

God forbid anyone gets hurt as a result of these known issues, but Marlin leave themselves wide open to criticism (litigation?) by not dealing with them more sympathetically.

Regards

Mike

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 17:33.

|