|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

19th May 2014, 20:13

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Looking really good Paul, you must be really pleased with what you've done!

Looks the part now.

|

20th May 2014, 14:24

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Gary - Thanks. I was amazed at just how solid everything felt when I bolted the frame to the bulkhead.

I have bought a load of plastic end caps to go in the rest of the rear frame work when all the welding is complete.

( As I am still thinking about welding the rear arches to the rear framework in some way. )

Michiel - Cheers. It will be a key stage of the build when I bolt these big parts to the chassis for the final time.

Scottie - Thanks. I am really pleased that my Frankenstein build approach looks like it might actually work.

It has taken a long time to get this far & there is still lots of work to do, but the "back bone" of this build is slowly coming together.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Monday

Despite the great weather, both my daughters were off school ill, so looking after them was my priority.

I did managed to move the rear frame work out of the way so my wife could park on the drive.

Also my new heavy duty tarpaulin finally arrived, so I was able to wrap it up before the rain returns.

I was meeting a friend in the evening when I came across a Jeep Cherokee on fire (driver was already safely out).

Unfortunately, by the time I'd parked my car out of the way & returned with my small extinguisher it was too late.

My fire fighting effort was really just a token gesture, as I only had a few seconds of powder available.

By then the police had arrived, with the fire brigade close behind and they took care of it with ease / a ton of water.

Many years ago, my motorcycle was on fire (long story  ), a man got out of his car, calmly put the fire out and drove off.

I've carried a fire extinguisher ever since in the hope that one day I could "pass forward" the favour that stranger did for me.

As I didn't actually put the fire out, I guess my "debt" is still outstanding, so I've ordered a new extinguisher for my Mondeo.

When I finally sort out the cockpit interior of my Cordite, I will make sure there is somewhere to fit an extinguisher there too.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Tuesday

With everyone back to school and no fires to content with, it was back to the build (in between my other chores)...

Rear Arches:

I welded on a small patch to a section of the rear wheel arches that had been trimmed a while back.

I trimmed a a bit off the hand brake panel where thin strips of an adjoining panel remained.

( This should allow the panel to sit better on top of the floors / framework. )

Not that easy to see in the 'before' & 'after' photos.

But this was the double panel thickness of the "shavings".

I also gave the top of the wheel arches a light trim too just to ensure maximum clearance to the body shell.

Before:

After:

Note:

I'm really pleased how "factory" the washer for the exhaust support bracket looks tucked into the wheel arch.

Then I did some general "tidying up" with the grinder including around the new chassis bolt holes before applying some Kurust.

Given the forecast was for rain, I stuck a cover over the arches just to be on the safe side.

Thankfully the rain hadn't started by the time the Kurust was dry, so I took a chance and put some black paint on.

Rear Frame:

Rear Frame:

I did another round of welding the lowered floor pans to the framework.

Even though there are still a few small gaps between the welds, it is more than strong enough.

So I will now cover all the edges with some fibreglass filler to seal the joins.

I also took my angle grinder to the corners of the mounting plates to "soften" them a bit.

( As I managed to catch and tear a cover on one sharp edge.  )

Next Steps:

Next Steps:

I want to have my first go at working with fibreglass to seal up a few holes in the rear aches.

By now I know I could do most of this repair work in metal, but I really want to get the hang of fibre glassing at this stage.

Once the repair work is done I will try to fit / join the arches and rear framework together.

Until next time, take care, Paul.

|

20th May 2014, 19:15

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, just my experience but those cheap plastic bungs seem to have a habit of cracking or eventually working their way out, for any tube ends I don't weld shut I just pump the ends full of PU adhesive and smooth with a wet finger, it gives a much more water tight seal, just make sure you've finished any welding in the area first though.

On the floor pan edges are you sure you need to fibreglass? Maybe just seal the perimeter with seam sealer?

Was hoping to make it back up the workshop myself this weekends s my gentlemen's parts are no longer the size of melons and are now just the size of good sized lemons :-0 unfortunately the project I'm on has hit snags so I'm going to have to work the bank holiday weekend, mind you time and a half Saturday and double time Sunday and Monday at my contractor rate will ease my pain.

Keep at it I will need something to read in the evenings in Weston super mare!

Mac

|

21st May 2014, 10:55

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Thanks for the tips about the end caps & I keep forgetting I have a tub of seal sealer to play with.

I'll try my best to provide you with some reading material while you are away from your garage...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Rear Arches:

Today was my first attempt at working with fibre glass so see if I could use it for some "simple" repairs.

There were "gaps" on both sides where the back of the wheel arch met the floor.

Plus one rush hole and a couple of factory holes I wanted to seal.

I followed the steps Mister Towed put in his build thread here.

So I cut out some mesh to place over the holes.

Then I cut out some fibre glass matting to go over the top of the mesh.

Given how messy this whole process was, that was the last photo I took until the work was finished.

( I can now related to Mr T's penguin reference.  )

Steps:

- Key the painted surfaces using a wire brush on the end of my drill.

- Mix up some resin and catalyst

- Apply resin

- Add mesh

- Then add matting and more resin

- Use roller to remove any air

It did take me a while to get the hang of what I was suppose to do.

Half of the first batch of resin had set in the mixing container before I could apply it.

The simple edges around the factory holes were easier to do than the curves around the rust holes.

I guess I will just have to see how/if it all sets before I will be able to tell if I have got it right.

However, the whole point of doing the repairs this way was to get some practice using fibre glass.

Also I should mention the NCIS "look" that I was sporting while doing this work.

- Cheap white decorator's "jump suit"

- Decent breathing mask

- Disposal rubber gloves

Question:

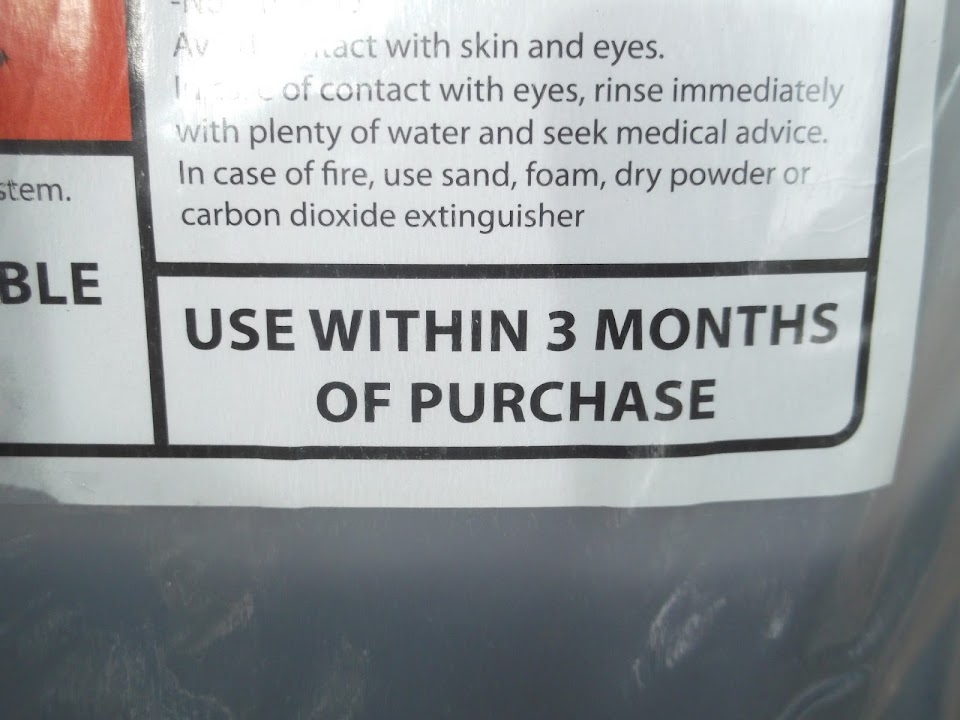

As I was packing up I noticed this label on the resin container...

This resin has actually been sitting in the garden shed for 18 months!

Does this mean that is is completely useless, or will it just set quicker than normal?

As always, your advice is most welcome.

Cheers, Paul.

|

21st May 2014, 12:50

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

you'll probably be fine, I used some recently that must have been more than 5 years old, it took a little longer to kick but other than that it was fine.

|

22nd May 2014, 18:11

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Thanks for the reply, I will keep using it for now and see how I get on.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I am stupid...

I only had a few minutes available for car work today, but unfortunately I discovered a stupid error I'd made.

With rain forecast after I'd used the fibreglass I'd moved the rear arches back under the tree and covered them up.

Now I remember adjusting the breeze block underneath the arches after I'd got most of the cover on.

But because I was just "kicking" it into position I didn't notice I'd hit the freshly fibre glassed repair panel.

So obviously this lifted the fibre glass away from the metal completely.

So forget kicking the breeze block, I could kick myself for messing up something so needlessly.

I will have a proper look at this another day and work out if anything can be saved, or if the whole lot has to come off.

Trying to stress the positive for a minute, the factory holes are sealed up nicely when looked at from below.

I will sand down the excess resin and run a layer of filler over this when I get the chance.

I also trimmed off the excess fibreglass from the other corner section.

Initially I did try to wrap this around the edge, but without success.

So I will do the other side as a separate exercise next time around.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Mac's Reading Material:

Obviously there isn't much to report on my own build, but below is a link to another build thread.

Sammio, Ribble, Miglia & Tribute kits all start with a donor car that you can then sell off unwanted parts.

Their current kits use Heralds, Spitfires, MX5s & Z3s as the starting point for the builds.

I don't think many of us would consider a build that started with a Bentley Continental as the donor car!

However, the end result is a 3,000hp street eliminator drag racer.

Read all about it here.

Read all about it here.

Until next time, take care, Paul.

|

23rd May 2014, 14:47

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Still chipping away...

First job of the day was to apply some Kurust to the bare metal where I welded the floors to the frame.

While that was drying I turned the frame over so I could seal the joins where the floors met the frame underneath.

Although I added some masking tape before slapping on the seam sealer.

Now this seam sealer stuff is still pretty new to me, but there did seem to be some sort of reaction with the paint??

I'd applied the stuff with an old cutlery knife and then went back to smooth it over with my finger (with a surgical glove on).

But the sealer stuck to the glove and came away from the metal.

So I "knifed" some more sealer on and left it to set to see it that makes any difference.

While I was waiting for the sealer to set I turned the frame back over again.

( Did I mention it was heavy?  )

This time I put some fibreglass filler over the welding on both sides of the "join" brackets.

( And on both sides of the frame. )

I know Mac recommended using the seam sealer here too, but I am not confident I'm using it properly.

There was then a bit of a break for some domestic chores and another short, but heavy, downpour.

When it was dry enough to return outside I started applying filler around the welded edges of the floor pans.

But no sooner had I started than the rain returned.

So it was back on with the cover and as I'm driving one of my daughters to a party soon, that is me done for the day.

The only good news is that this new heavy duty tarpaulin does seem to keep the water out ( touch wood).

More Recycling:

A house a few doors down from us is having a loft conversion done (we seem to have started a trend).

So with their permission I collected a selection of wood that was sitting in the skip ready to be dumped.

At some point I need to get the rolling chassis level horizontally to check the fit of the body shell.

So I will use this wood and my axle stands to prop everything up until I have a basis level to work with.

Until next time, take care, Paul.

PS

Some more light reading for Mac...

How about the world's fastest Postman Pat amusement ride?

( You know the sort of thing usually found outside supermarkets for small children to "drive". )

I guarantee that some of the video clips on the link below will bring a smile to your face.  Click Here.

Click Here.

Last edited by Paul L; 24th May 2014 at 06:40..

Reason: Typo

|

23rd May 2014, 15:16

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Well done Paul, your volume of work is putting me to shame!

I don't so much think I'm "working" on my build, more like "fannying around" at the moment!!

|

23rd May 2014, 16:14

|

|

Senior Member

|

|

Join Date: Jun 2011

Location: birchington, kent

Posts: 1,769

|

|

Paul, i assumed it should go on bare metal, the spray over the top?

|

24th May 2014, 11:38

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - Well there has been some biblical "fannying around" on my build at times.  Gary

Gary - You may be right, as the bulkhead was in primer when I first used this stuff.

But I have thought of a "Plan B", see below...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Small break in the rain...

I have learnt the hard way not to push my luck too much when the weather forecast is rubbish.

So with only a very limited dry spell available I started by sorting out the bulkhead "join" brackets.

I did have to move the frame first, as there was very little room to manoeuvre where it was.

I even remembered that I now have a pile of wooden blocks that I can use to rest it on.

Then I quickly tidied up the filler with my angle grinder, belt sander & some sand paper.

Obviously as I am tidying up one thing, I am making a mess of another.

Before getting some more etch primer over the top of the brackets.

I must confess I am really happy with how these brackets have turned out.

By now the sun had appeared, so I tidied up the filler on the floor edges I'd covered yesterday.

Then I gave them a quick blast of primer too.

Then I put some fibreglass filler on the remaining edges of the floor pans.

But by now my luck had run out and the first drops of rain were arriving.

So I just had time to carry the frame back out of the way and cover it all up.

Still, at least I have made another little bit of progress in the right direction.

Hope those of you with dry garages are able to have a more productive Bank Holiday weekend.

Good luck, Paul.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Seam Sealer vs. Fibreglass Resin

Thankfully today's work involved leaving the rear frame "sunny side" up.

As I am not looking forward to turning it over and seeing if the seam sealer has worked.

But what did occur to me was the resin mix I used on the rear aches would have done the same job.

Forget adding fibreglass, just paint on the resin and any gaps would be sealed.

At least that is my theory and it will be my "Plan B" is the seam sealer has not stuck.

( If the weather holds, I'm going to bite the bullet and check it tomorrow.  )

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Mac's Reading Corner:

I am always amazed at the skills other people display working on their cars.

So here is another one of my favourite build threads from Rods 'n' Sods.

From this...

To this...

Details Here.

Details Here.

This build is also really tempting me to attempt to paint my car by hand when the time comes.

Painting with rollers.

|

24th May 2014, 12:38

|

|

Senior Member

|

|

Join Date: Aug 2012

Location: Teesside

Posts: 234

|

|

|

24th May 2014, 14:35

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 113

|

|

I painted my Sammio by hand and result is not bad.The only problem I

have is that the paint is very "soft",it get,s scratches very easy...

Probably because it is on polyester?

I used a 1K industrial coat ,but i thinkthe problem with the polyester is

that i couldn,t find a""high build filling-primer"i could apply with a roller.

When i sort this problem I can imagine painting it another time  |

25th May 2014, 19:45

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mas123Mas & Jerome - It is good to know that hand painting is a real option.

I still have some more research to do, but I have found "marine" paint designed for fibreglass.

Unfortunately, I am still a long way from worrying about painting my car.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Sunday Service - Part 1

First job of the day was a family trip out to see the latest, time travelling, X-Men film.

I did get the chance to do a number of small jobs in the late afternoon sunshine...

The filler I applied to the remaining edges of the floors yesterday was "tidied up".

I just about managed to get some etch primer on these edges before running out of paint.

( More primer is on its way. )

Note:

I remembered to put a dust sheet down today after I got primer on my drive yesterday.

The "join" brackets got their first coat of black paint.

I also painted the front and inside edges of the floors as they were primed yesterday.

While the rear frame was "drying" on the drive, I switched my attention to the rear arches in the back garden...

|

25th May 2014, 19:46

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Sunday Service - Part 2

I cleaned up the excess resin and applied some fibreglass filler to the underside of the "factory" holes I'd sealed.

I also put some filler "behind" one of the corner holes I'd repaired with fibreglass on the other side.

Note: I plan to seal this in with a layer of fibreglass when I start working on the underside of the arches.

Then I had a close look at the corner where I had dislodged the fibreglass repair.

I started by simply trimming off the excess.

Then I cut a section out, but in the end I knew the whole thing had to go.

So I had another chance to practise my fibreglassing skills and I made a few changes this time.

The first was drilling some holes so I could use rivets to hold the mesh in place.

This gave me one less thing to worry about, as previously the mesh was moving, as well as the fibreglass matting.

I then used 4 smaller strips of fibreglass matting rather than one big one to cover the hole.

I also used some cardboard as a workbench to apply the resin to one side of the matting before putting it on the arches.

I used a 1.5% mix as it was quite warm out and I needed all the working time I could get.

These little changes, coupled with my experience from the first go, did seem to make a positive difference.

I will add another layer of matting over the top of this one on another day.

I know you can add extra layers at the same time, but I didn't want to push my luck while this is all new to me.

Just before I uploaded these posts I tucked the arches away for the night, taking a lot more care with the fresh fibreglass than last time!

Until next time, take care, Paul.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Mac's Reading Corner:

Another example of metal work magic...

Taking an old 4 door Cortina and turning it into a 2 door that would pass as factory.

Details Here.

|

27th May 2014, 16:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Rain stops play...

Unfortunately, Monday was a complete wash out and today hasn't been much better.

But, thankfully, I do have a tiny bit of progress to report...

I roughed up the fibreglass repairs on the rear wheel arches.

Then I set myself up for another round of messy fibreglass work.

Note: My cheap skate, disposable, resin mixing containers.

I managed to add another layer of fibreglass matting to all the areas.

That should do it for this side, but I will add fibreglass to the other side of the bigger patches.

Cheers, Paul.

|

28th May 2014, 16:30

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul,

thanks for the reading matter!

On your post about using pure resin to fill gaps...don't do it, resin on its own will be far to brittle. What you can do is make your own fibreglass filler, chop some matting up into very small pieces and mix with some resin until you get a thick gloopy mixture which will do the same job as the fibreglass filler you have been using.

HTH

Mac

|

28th May 2014, 16:40

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - I hope the links took your mind off being away from your garage and thanks for the resin tip.

I've been waiting for the sun to return before I unwrapped the rear frame and have a look at the seam sealer.

At the very least, all these rain delays will have given the stuff plenty of time to set.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Play misty for me...

It has been hard to get anything done during this run of rubbish weather, but I am trying to do something when I can.

Thankfully the tarpaulin kept most of the rain off yesterday's fibreglass repairs.

I decided to leave those areas to cure a bit longer before I tidied them up in preparation for paint.

Instead, I just turned the arches over, so I could start work on the other side.

I started by cleaning up the filler I had applied on the underside of the "factory" holes I'd sealed previously.

( Sorry the photo is a bit blurred. )

After the fibreglass work below, I managed to quickly get some primer on the two "holes".

As far as the "factory" holes are concerned, apart from some black paint, they are now complete.

Just before I started on the next round of fibreglassing, I cut off the backs of the pop rivets I'd used on the mesh.

( Another poor photo. )

I also trimmed off the excess fibreglass from the corner that I had damaged and re-done.

Not sure what happened to the "before" photo, as I was sure I had taken one?

Then I used some mesh to build up the edges on one of the inside corner repairs.

One tip I'd picked up from another build was to mask off the handles of my brush & roller.

This does speed up the cleaning process a little bit, as I only have to worry about the ends.

My plan was always to re-enforce the other side of the big gaps like this one.

The reason for doing these repairs in fibreglass, and not metal, in the first place was to get the practice.

And based on today's efforts I certainly need more practise.

I managed to successfully build up several layers of small sections of matting behind the big gap seen above.

But the mesh re-enforced corner section didn't go as smoothly, although the side doesn't look too bad.

Where I tried to fold it over the edge didn't work out as well as I hoped.

So I simply started on the other corner repair and just covered some of the filler I'd put in there.

My initial plan was to attempt to add extra layers of matting in all three of these areas before the first batch set.

But I am happy to take my time and tidy up this round of work before I come back to it and finish it off another day.

I am still a beginner and there is no point in rushing this if I then have to come back and do it all again.

So this is how the underside of the arches look now.

Just before I updated this post, the fibreglass was dry enough for me to pull the cover over the top.

( As it looks like the rain will be returning any minute. )

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Gardener's World

Whilst the rain isn't doing my build any favours, the garden has gone a bit mad in terms of stuff growing.

We have a big family bash at our house on Saturday, so I was forced to do most of the pruning in the drizzle.

At least our new vegetable patch is coming on nicely.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Without a decent run of dry weather, I'll just have to accept that progress will be slow.

So until next time, take care, Paul.

|

28th May 2014, 21:26

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

Quote:

Originally Posted by Viatron

On your post about using pure resin to fill gaps...don't do it, resin on its own will be far to brittle. What you can do is make your own fibreglass filler, chop some matting up into very small pieces and mix with some resin until you get a thick gloopy mixture which will do the same job as the fibreglass filler you have been using.

HTH

Mac

|

Always keeps those little offcuts. You can make them look like this....

|

29th May 2014, 15:44

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Oxford - I vaguely remember you mixing that up, so I'll go back and have another read of your build thread.

Talking of which, have you had the chance to make any progress on your own car?

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Tidying, fibreglassing, gardening & raining...

First job of the day was to shift all the tools and bits that were in the dining room to the Summer House.

Now, the only thing left indoors is one of the seats.

As I hope to visit a seat seller tomorrow and want to make a side by side comparison.

The only car work I had the chance to do was to add more fibreglass matting to the rear arches repairs.

But to be honest I am still struggling to "fold" the matting over edges.

So I will continue to build these areas up in smaller steps until I get the hang of it.

Finally I finished "edging" the lawn, which is seriously back breaking work using hand shears.

So the good news is that the house is now almost ready for our guests on Saturday.

Which means I might be able to spend a bit more time on the car tomorrow.

Cheers, Paul.

|

30th May 2014, 19:55

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Drizzle...

My master plan of doing waves of fibre glassing from first thing in the morning disappeared in the waves of fine mist in the air.

However, I did managed a rare piece of male multi-tasking, combining chauffeur duties for my wife & daughter with a visit to an ebay seat seller.

Now I remember Mister Towed's very valid point that certain types of bucket seat just don't belong in these cars.

Also based on Google images, I can't find a single Sammio / Ribble with this type of seat fitted.

But I really like the idea of built in guides for the shoulder straps of my racing harness arrangement.

So these are the seats I went to look at...

I had thrown my "problem" seat in the back of the car, so here is a side by side comparison.

This is how that seat looked when I test fitted the passenger side recently.

The back of bucket seat can be adjusted so that it is not reclining and this would allow it to move further back.

This in turn would allow it to sit lower in lowered floor pans, something the angle of the current seat back prevents.

The end result would be that very little of the top of the seat (apart from the head rest) would be proud of the bodywork.

( At least that is what I think / hope. )

All I did do today was take some measurements and I will need to have another look at the car when the frame and body and back on.

It is a big decision and so I will take my time and if this doesn't work I'll find something else.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

The middle of the day was another half term trip to the cinema with one of my daughters for the latest Tom Cruise blockbuster.

( Which was basically Groundhog Day, but with guns and aliens.  )

By early evening I just managed to do another round of fibre glassing on the rear arches.

I still can't do a decent job of working the matting around edges and making it stick.

So I decided to simply leave the edges "hanging" and simply join them from the other side during the next round.

The only good news is that my previous fibreglass work is setting nice and hard.

( I ground away any dodgy bits where I'd previously messed up on the edges. )

Obviously the weather has meant this has all taken much longer than I expected.

Still, any progress is good progress at the moment.

Until next time, take care, Paul.

|

|

Currently Active Users Viewing This Thread: 2 (0 members and 2 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 14:25.

|