|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

27th November 2013, 18:35

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, nothing like unpacking new shiny stuff, especially if your a bit under the weather. I went for the bare minimum with mine as im not planning to have any dash vents as

1. I couldn't find any that looked period enough

2. I have gone for a bigger heater and am hoping that having it running will fill the under dash are and foot wells with hot air which will then spill into the cockpit area.

Hope you feel better soon

Mac

PS thanks for the PM, yes I was aware but thanks for the heads up anyway.

|

28th November 2013, 18:47

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - The previous owner said that a carpenter mate of his made the dash as a one off.

However, it is a bit ropey in places, so I am prepared to "cut & shunt" it about to form the backbone of a new dash.

Whilst the plan is vague, basically when everything is in the right position, I'll put a uniform surface over the top of the dash.

So in theory, all the dials & switches will sit it their original mountings, but you won't see the relocating "joins".

Mac - As always, I wasn't very clear about my plans for the dash vents.

The heater vents will not be mounted into the dash board itself, but behind/underneath it "somehow".

Hopefully they will point at the front foot wells to heat the car in the way you described.

In this photo you can see the bracket below the dash that was originally connected vertically to the chassis.

Again, the vague plan is to use this in someway to link the front of the dash horizontally to the back of the bulkhead.

If I could bend the whole thing backwards 90 degrees, then it would largely disappear from view at the front.

Then, with a bit of luck, those two brackets currently pointed downwards could be used to help hold the vents in place.

Admittedly, the heater control & fan speed switches will stick out as modern fittings.

But I hope it will look like I've added a modern heater to an old racing car I found in a barn.

Certainly my "rough & ready" approach to finishing the bulkhead is in keeping with a barn find!

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Minor Tinkering...

I'm still under the weather, so only spend a very short time outside working on the car.

I needed to fill this hole.

So I cut out & cleaned up two repair panels.

Then welded them in.

Then I covered the area in Kurust.

This is the view from inside that corner and the hole will disappear when the filler get applied.

Rather than just patch a small hole, I made the repair panel oversize to add strength to the corner.

I've removed quite a bit of rot and some dodgy repair panels from this bottom corner.

So I have run some welds along various edges to hold it all together.

Another liberal coating of Kurust.

Now all I need to do is cover this mess in filler.

Initially I was thinking of making some sort of sill panel to cover this whole area.

But then I remembered that the fibre glass body will cover it completely.

I just need to make sure I join/seal the bodywork to the bulkhead properly.

Moon Rover Plans:

I know there will be a shed load of bodywork / fibre glassing to do once the current metal work repairs are completed.

Previously, others have suggested getting the body bonded on before worrying about restarting the engine.

However, I think getting the car to a stage where I could start and drive it again would be a big real motivator.

So my current plan is to build a working "moon rover" as seen here, driven by AndyP57.

Mind you, I'm still a long way from getting to this stage at the moment.

So I'll worry about the finer details another day.

Until next time, take care, Paul.

|

28th November 2013, 20:22

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Paul,

It seems a shame to cover such a nice dash, but I'm not looking at it from your end!

I think your plan to start the engine first is a good one. When I stripped my Spit, ( although all the dials and dash are off) the car remained, and still is, drivable.

Like you say, its mainly a mind thing, but it is practical at the same time.

I found it so useful to be able to move the car about, go for it!

|

29th November 2013, 16:16

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - The only way I think I could save any of the dash is by making the changes I need very obvious.

E.g. Put the new heater controls on a metal backing plate & bolt the whole lot over the top of the wood.

Again, this might give the impression of modern alterations to an older car, I'll certainly have a think.

I love the way that the Tribute approach to the A352 build allows the Spitfire to be kept as a runner.

Unfortunately, when the A352 was first put together for the Exeter show I was already knee deep in this build.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Still Just Tinkering...

Today's very brief venture outside allowed me to weld the final end cap to my external support structure.

I also put some filler on yesterday's bulkhead corner "hole" repair.

- Above

- Front

- Inside

As darkness fell it was time to pack up, as the cold is certainly not helping me to recover.

But at least I made a start on applying the filler on the outside of the bulkhead.

I also took the advice of Tribute "next door" and ordered some Fibral.

It is certainly cheaper than P40 and so far the squeezy tube is easy to use too.

The only other thing I managed to do was cut & shape the mesh to help seal off the A Pillar.

It will cover both the top of the pillar and the bottom of the windscreen support sections.

Hopefully one of these days I will get the chance to fibre glass this mesh into place.

Until next time, take care, Paul.

|

30th November 2013, 13:47

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Flying Visit...

I've been very busy today, unfortunately on domestic chores, not car work.

Still, I did managed to get two quick jobs done...

Added some more filler to the outside of the bulkhead.

I know it looks a complete mess, but that is all the welding / panel joins covered.

I also roughly sanded down the filler on the outside of the corner repair & got some primer on it.

By the time I've brushed on some black paint, this will look just as "good" as the rest of the bulkhead.

Anyway, I'm supposed to be doing something else, so got to go, Paul.

|

30th November 2013, 17:34

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Getting there Paul, is that all the welding done now? Put your grip tape in the post this evening first class so start looking out for it in January! :-)

Mac

|

1st December 2013, 16:49

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Unfortunately, I've only finished the welding on the driver's side of the bulkhead.

I still need to do the passenger side (see below) & the inside edges where the gearbox tunnel fits.

Thanks again for sending the grip tape, I am looking forward to fitting parts back on the bulkhead.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Slow Progress:

My wife went to visit her sister and took our girls with her, so I headed outside to see what I could do.

It was too early on a Sunday morning to start the angle grinder up, so I started looking at the passenger side of the bulkhead.

The good news is that this is in much better shape than the driver's side was.

But there is still a lot of work to do, including a number of rust holes to sort out.

Plus repairs to the "A" Pillar, that thankfully will not be as hard to do as the other side was.

I decided the "screwdriver of truth" could be used without disturbing the neighbours.

As always, some of the rusty areas are a little bigger than they first appear.

Plus the old seam sealer continues to breed rust in places.

Note: Sorting out the badly repaired battery box is also on the "to do" list.

When I could get the grinder & belt sander working I roughly cleaned up the filler on the driver's side.

Once I'd brushed away all the filler dust, it became clear that I had missed filling a couple of spots.

( I blame working in the dark, under the influence of cough mixture.  )

So I simply masked these two areas off & then put a coat of primer over the top of the rest.

( You can see the bits I missed, the box section at the back and a little area at the side. )

This is how the front edge of the repair panel I'd previously welded into place now looks.

Then I put some filler over the two sections I missed.

I then switched back to the passenger side and cleaned up some more of the inside.

I am going to start the repairs from the inside of the bulkhead this time.

So I cut up and cleaned up the first three repair panels that I cover some of the "factory" holes.

I also gave the "inside" faces a coat of weldable primer.

I also coated the inside of the "A" Pillar with anti-rust treatment.

But I ran out of time to start welding, hopefully I'll get a chance to do that tomorrow.

Cheers, Paul.

|

2nd December 2013, 16:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Monday - Part 1

This was one of those days were all your good intentions go out of the window.

I did manage to get a few of my planned jobs done, but the build had its own ideas.

The following is not in chronological order, but hopefully it is easier to follow this way.

Driver's Side:

I roughly sanded down the two areas of filler I put on yesterday and put some primer on.

I also remembered to finish off the inside of the front corner repair I did the other day.

( Note that is dust/rubbish sitting on top of the grey paint in places, not more rust. )

Passenger Side:

I set about welding panels over the factory holes in the bulkhead I no longer need.

"A" Pillar

"A" Pillar

Side Wall

So far, so good...

I'd prepared a panel for this hole yesterday.

Although I was planning to trim the "holey" bottom right corner out before I welded it into palce.

However, the more I looked at that bottom section, the more suspicious I got about the state of the metal.

Even though I knew I was making more work for myself, I knew I wanted to do a proper repair job.

So I started to cut & peel away the whole bottom section...

Which revealed the way that rust had developed & eaten away the driver's side.

The area to the right of this was also pretty rotten.

Although this seems to be linked to a previous repair when you look from the outside.

( Sorry the photo isn't great. )

My approach of starting from the inside and working out was beginning to back fire a bit.

I couldn't cut all the rot out as there would be nothing left to hold the bulkhead in position.

So I decide to make a repair panel in two parts and get the first part in before final cutting.

Although I started with my previous repair panel, which was now too big.

After cutting it back a bit, it was welded in.

And this is what the "A" Pillar was looking like now.

Then after welding in the first part of my repair panel it looked like this.

As before, just this small section of metal really made a difference in the stiffness of the bulkhead.

So next time I will start cutting out the rot and putting more repair panels in.

I'll be back in a minute with Part 2...

|

2nd December 2013, 17:00

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Monday - Part 2

The other area when it all went wrong were these two holes used for the original bonnet catch.

I knew there were a few pin holes to sort out, but wasn't too worried.

However, after a complete nightmare of blowing holes everywhere I had to admit defeat.

The area on the left side of this photo was just too thin to weld properly.

( Well for me anyway.  )

By this point I was getting pretty fed up with rust damage so I took some drastic action.

I cut the whole mess out and cleaned up the area ready for a much bigger repair panel.

By now it was also getting dark & as I am still not 100%, it was time to call it a day.

So I simply tacked the repair panel into place and will hopefully finish it off tomorrow.

These bulkhead repairs have certainly been more extensive than I was expecting.

But I am determined not to take short cuts that that would only "look good".

Whilst I know my filler work is rough, it is all over solid metal, so I am happy.

Seam Sealer Question:

Obviously I have been digging the old stuff out and fixing all the mess underneath it.

What are people's views on the correct sequence for using the new stuff I have bought?

So far, I have repaired & applied anti-rust treatment to the old metal seams.

Then I have then put a coat of primer over the top of that.

Does the new seam sealer go on next, with the black paint over the top of that?

Or do you put the first layer of paint on, then the sealer, then more paint?

Any "answers on a postcard to the usual address" would be most welcome.

Cheers, Paul.

|

2nd December 2013, 17:12

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 159

|

|

Hey Paul,

Keep it up, you're getting there eventually. Normally these sealers can be painted, which suggest that you use it first. In my case the metal was all ready prepped and had a primer. And I think this is the best way. First use treatment and primer (which can penetrate all the little gaps and holes. Then the sealant and on top of that a top coat of paint.

Not sure though, but it looks like a logical method.

Michiel

|

2nd December 2013, 18:26

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Yep, primer first then seam sealer then final colour over the lot, keep going Paul youre getting there and at this rate you can always take up welding instead of bean counting !  |

3rd December 2013, 16:26

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Michiel & Mac - Thanks for the replies chaps, that is a big help.

I will wait until all the repair work is finished & then apply the sealer in one go.

Thanks also to Scottie who sent me a few welding tips via a PM last night.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Inching Forward...

There was another simple thing I could do to improve my welding...

Yes, a stool/step which made it easier for me to reach the side of the bulkhead.

First job of the day was to weld in the panel I had tacked on (badly) last night.

I think that looks like a slightly better job even before I cleaned up the welds.

Late in the day I also put some anti-rust treatment on this.

The top of the "A" Pillar is in a much better condition than the driver's side.

So I simply cleaned it up a bit...

Treated it...

Left that for a few hours to dry, then covered it in filler, after putting a small metal circle over the hole.

There was a bit of filler left over which I use to cover one of the welded up "holes".

I also welded up two more of the factory holes in the "A" Pillar.

( These really are very difficult to get any sort of decent access to. )

Then I cut a section of the rust / rot out.

Whilst Midas could turn everything he touched into gold...

Everything I touch on this bulkhead seems to turning into a rusty mess.

In an attempt to sort this out once and for all, I need to cut even more out.

But, as before, I don't want to keep cutting without putting some strength back in first.

So I decided to make the next repair panel in two sections, rather than a single piece as originally planned.

I am very conscious this "A" Pillar will be a patchwork quilt by the time I'm finished.

Even so, welding this panel in now will support the next round of cutting.

Although I may actually sort out an external support structure similar to the driver's side first.

As once again there is wholesale rot along the bottom edge here.

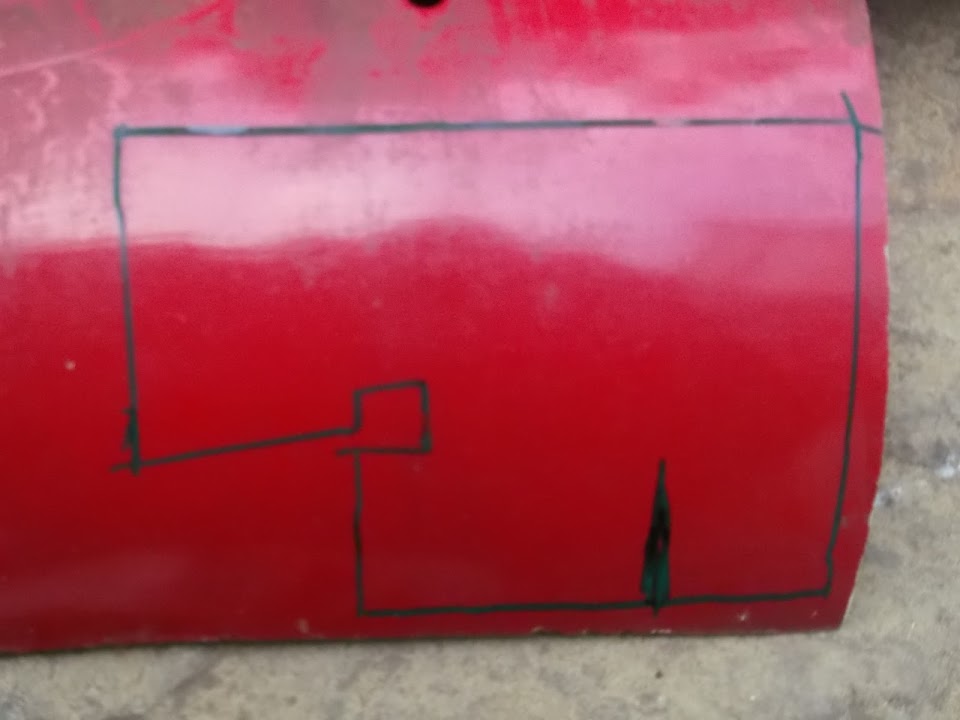

Whilst I had considered a simple patch like this...

It might still be worth going back to a more over engineered solution, so I will have a think.

Until next time, take care, Paul.

|

4th December 2013, 19:06

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

I just cannot believe there is that much surface area on a Spit body!

You must have constructed almost a complete car out of patches and bits Paul!

It makes me realise how lucky I was to get a 42 year old rust-free Spitfire.

I needed just two or three tin lid size patches which took no time at all.

You must surely run out of welding jobs soon?

|

5th December 2013, 07:34

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

I feel what you're going through with the welding, but at least it's "fun"  |

5th December 2013, 09:39

|

|

Senior Member

|

|

Join Date: Aug 2012

Location: Surrey/Sussex border

Posts: 169

|

|

Good work. Glad I splashed out a fair wedge on my 1966 Herald. So far not had to do any welding.

Slarti

|

5th December 2013, 16:09

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie, Dave & Slarti - Cheers gentlemen, I think I'm over the half way point on welding the bulkhead.

The irony of all this is that I too paid over the odds for a rust free Spitfire donor.

I sold that tub because I had nowhere to store it & I was not supposed to need it anyway.

If I knew then, what I know now, this build would have been done in a completely different way.

( That is assuming I would still have touched the original Cordite kit with a barge pole. )

As always, please remember that the new Ribble Navigator does not have these problems.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Before I start my update, I want to say of thanks to Mac ( Viatron) for sending me this...

It is some of the skate board grip tape that he used on his pedals, which I will use on the Spitfire accelerator pedal.

( Plus some jelly tots too. )

There is already a long list of people I need to buy a beer when this build is done.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Christmas Count Down...

My time available to play with the car is now being cut short by the requirements of Christmas.

I seriously need to get my act together in the next week to break the back of festive things to do.

So nothing at all yesterday, but a little bit of work done today (despite the high winds).

The more I look at the passenger side of the bulkhead, the worse it gets.

( Note: I've turned the photo "upside down" so the bulkhead is the right way up. )

There have been a number of previous repairs which haven't helped.

So to do the job properly, all this dodgy metal work had to go.

( Note: I will remove the bottom edge when the top edge has been sorted out / welded. )

I then cleaned it up with the grinder & got some anti rust treatment on it.

I am going to build an external support structure like the one I used on the driver's side.

So I needed to cut a selection of box section to do the job.

Which left my Cordite bulkhead looking a little more "compact".

I hope to recycle more of this framework to build the "join" from rear frame to bulkhead.

Using the welding glove on my left hand as a wind break I got to work.

( Think how a smoker lights up on a windy day. )

Note: The box is not square, as the space it fits into isn't either.

The rain came before I could get any further on the welding, but I had finished a few other little jobs by this point.

The factory hole on this edge had a lip on the inside that would foul the external support box section.

Which just needed a little trim / grind to flatten it out at the bottom.

I will weld the "fill in" panel from the other side this time around.

I also got some filler onto the welds around the repair patch where the bonnet catch used to mount.

I used the last bit of filler I'd mixed over some of the repairs around the "A" Pillar.

Until next time, take care, Paul.

|

6th December 2013, 15:32

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

A bit of prep. work...

If this bulkhead had been a horse, it would have been put down by now, to save it from further suffering.

I grabbed the little time I had available to continue building my external support structure.

This is the section I have already completed just resting in place.

The bulkhead metal that the box section "box" is resting on is rotten and needs to be cut out.

This will let the box section "drop" a little as you look at the photo (obviously the bulkhead is upside down).

Which, in turn, will close the gap that a repair panel will need to bridge.

I then started capping some of the ends of the box section before the final welding.

Then the next section of the external support went on.

I ground out small notches on both edges of the final joint as it needs to be at a slight angle.

Then I clamped the two parts to the bulkhead and tack welded them where they joined.

Once it was joined I could remove everything and finish off the welding.

This is what it looks like in its final position.

All I need to do now is make all the repair panels I need and weld them into place.

The "A" Pillar repair work already completed is still holding the bulkhead in place.

So it should be more straightforward this time around (touch wood).

Christmas tree goes up tomorrow, so not sure if I will get a chance to play.

Cheers, Paul.

|

6th December 2013, 18:22

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Christmas tree tomorrow!!1 had to persuade my Missus not to stay up until 1 minute past midnight on the 30th!

|

7th December 2013, 16:51

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Well my children want the tree up on the 1st, but my wife would prefer it went up just a few days before.

So I get to play UN peace keeper & pick a date in the middle, but closer to the girls' wishes (well, it is Christmas).

This year they were given full, unsupervised, control of decorating the tree, rather than just help me do it.

We are firm believers in the "more is more" approach to Christmas trees and here it is...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

With apologies to Irvine Welsh...

Bulkheadspotting

"Choose life. Choose a job. Choose a career. Choose a family. Choose a big television, Choose washing machines, cars, compact disc players, and electrical tin can openers. Choose good health, low cholesterol and dental insurance. Choose fixed-interest mortgage repayments. Choose a starter home. Choose your friends. Choose leisure wear and matching luggage. Choose a three piece suit on hire purchase in a range of fabrics. Choose DIY. Choose sitting on that couch watching mind-numbing spirit-crushing game shows, stuffing junk food into your mouth. Choose your future. Choose life . . .

But why would I want to do a thing like that? I chose not to choose life. I chose something else. And the reasons? There are no reasons.

Who needs reasons when you've got a 40 year old rusty piece of metal to repair?"

I did get a brief spell outside and a couple of small jobs under my belt.

The first was making a cardboard template for a repair panel.

Which I marked up, cut out & cleaned up.

I just need to cut out a little bit more so it will fit around the box section.

I also need to make another minor adjustment before I fix it.

I had put black tape over the holes for door hinge mountings to keep the rubbish out.

But I only remembered this when I started to clean up the metal ready for welding.

The "Trainspotting" quote above came to mind while I was trying to work out the other repair panels needed.

The hunt for good metal to weld the repair panels to was really starting to do my head in.

But, in the end, I knew I needed to cut even more rust out and just get on with it.

I can a section of metal left over from the panel I started repairing the "A" Pillar with.

So I welded that in as a brace between two sections of the bulkhead.

This allowed me to cut the entire join between these two panels out once & for all.

The external box section support will cover this hole, so I needed to remove the rot before I welded that into position.

By now, the sun had gone down and the temperature was rapidly following it.

So I called it a night and with a bit of luck I will get to start welding it all back together tomorrow.

Well that is assuming I get a whole butch of Christmas cards written tonight.

Cheers, Paul.

PS

Living in London, it is not unusual to have Police / Medical helicopters overhead.

I guess last week's tragic accident makes you a bit more aware of them than usual.

But while I was working on the bulkhead this one was circling particularly low.

Thankfully as it dropped below the roof lines it was just landing in the local park to collect & take someone to hospital.

So no matter now bad the bulkhead is, I don't confuse this with a real problem.

"Let's be careful out there."

|

7th December 2013, 20:18

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

That Trainspotting quote (ish) has made me dig my copy out thing i may have to watch it tonight after SWMBO have gonr to bed.

|

|

Currently Active Users Viewing This Thread: 4 (0 members and 4 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 18:44.

|