|

|

| Vintage and Classic Roadster Kit Car Builds For Vintage and Classic era kit cars. Post your build reports, problems and progress here |

4th June 2021, 18:29

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Not much to report over the last couple of weeks due to other priorities.

But, I've now re-fitted the rear silencer box with the new connectors. A much better fit than the previous ones and now hopefully gas tight. I just need to tidy up with a bit a paint on the exposed pipes.

New exhaust connectors New exhaust connectors by Sabrebuilder, on Flickr

I've also fitted an additional 2 way fuse box. One new fuse for the auxiliary power socket and one for the positive feed to the wiper switch which wasn't fused by the original main fuse box. The new fuse box is under the dash, just to the right of the steering column.

Aux fuse box Aux fuse box by Sabrebuilder, on Flickr

That's all for now, stay safe.........

,,,,,,,,,,,peter |

4th June 2021, 18:59

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Progress is progress nonetheless. Keep at it!

|

13th June 2021, 21:11

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by molleur

Progress is progress nonetheless. Keep at it!

|

Thanks, indeed it is.

I'm gradually nibbling my way through my list of jobs.......

This week I fitted the windscreen. I used Sikaflex 255FC Adhesive. Bit of a messy job but I got there in the end.

Windscreen Fitted Windscreen Fitted by Sabrebuilder, on Flickr

The all important marking for the IVA test.

Windscreen approval mark Windscreen approval mark by Sabrebuilder, on Flickr

A few days later I fitted the 'plastic chrome' trim surround. A very time consuming job to get the mitres and lengths correct.

Windscreen surround Windscreen surround by Sabrebuilder, on Flickr

I've also fitted the Interior Light door switches. It's practically impossible to get to the rear of the switches due to the 'A' pillar support structure so I soldered on the wires. The wire loops are to allow movement of the plunger.

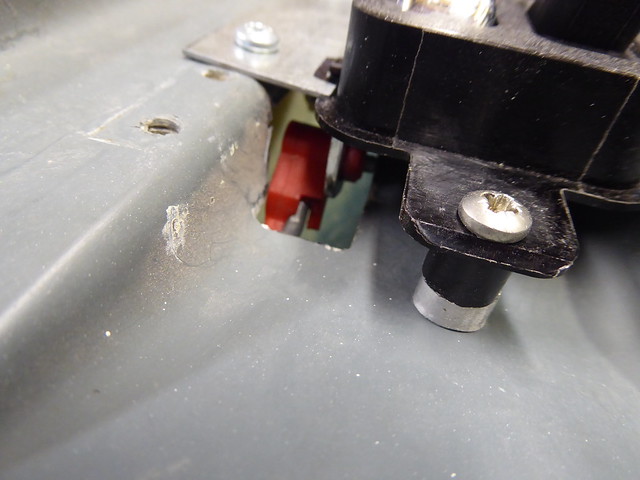

Interior Light Door switches Interior Light Door switches by Sabrebuilder, on Flickr

And here's one fitted....

Interior Light Door switches Interior Light Door switches by Sabrebuilder, on Flickr

The lens on my phone camera has made the length of the plunger look much longer than it really is. The plungers will be trimmed to size once the doors are fitted.

So that's another two jobs done!

Stay safe.........Peter

|

13th June 2021, 23:21

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

a bit like eating the elephant. One bite at a time.

Looking good, especially the plastic chrome trim. Well done.

|

14th June 2021, 09:10

|

|

Senior Member

|

|

Join Date: Nov 2017

Posts: 109

|

|

Quote:

Originally Posted by molleur

Looking good, especially the plastic chrome trim. Well done.

|

Agreed! That screen looks ace  I bet that feels like a pretty big milestone. |

19th June 2021, 20:11

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by kon

Agreed! That screen looks ace  I bet that feels like a pretty big milestone. |

Thanks Jack and Kon. Some steps make a dramatic impact but others like this week when I have been doing some more mundane but equally important tasks.

I've been doing some more wiring before refitting the dashboard surround. Hopefully this will be the end of the wiring which can take a surprisingly long time for very little to show.

I been running in some extra cables like a supply to the boot for a boot light, some speaker cables and an aerial cable to the boot. The aerial will be fitted after the IVA test.

I've also been connecting up the interior light cables and running supply and illumination cables for the heater control. Plus a lot tidying up to make all the cables secure and IVA compliant.

All the unused wires to the ECU have been terminated in insulated closed end connectors and then encased in some conduit.

Unused ECU cables Unused ECU cables by Sabrebuilder, on Flickr

And then tied up under the dash.

Under dash wiring (passenger side) Under dash wiring (passenger side) by Sabrebuilder, on Flickr

This required the 'head in the footwell' pose

Then taking a break from wiring, I made up a mounting panel for the intermittent wiper control unit. This will be later fixed at a convenient point along the lower edge of the dashboard surround.

Wiper delay panel Wiper delay panel by Sabrebuilder, on Flickr

So a few more nibbles out of the elephant and edging slowly towards the finish line

Stay safe.............peter

|

19th June 2021, 21:08

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Your little wiper delay panel turn out nicely!

Another small bite.

|

20th June 2021, 04:59

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Quote:

Originally Posted by peterux

This required the 'head in the footwell' pose  |

I feel your pain!

Quote:

Originally Posted by peterux

Then taking a break from wiring, I made up a mounting panel for the intermittent wiper control unit. This will be later fixed at a convenient point along the lower edge of the dashboard surround.

Wiper delay panel Wiper delay panel by Sabrebuilder, on Flickr

So a few more nibbles out of the elephant and edging slowly towards the finish line

Stay safe.............peter |

Very neat work! Small steps maybe, but you're getting there

Regards, Mick |

25th June 2021, 19:22

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

You never stop learning things...

You never stop learning things...

A little lesson on the Ford Sierra steering column that might be useful to other builders.

After what seemed like hours of sitting in the drivers seat fiddly about with wiring to make it all neat and secure I noticed that I had a small amount of play in my steering column around the lower of the two upper column bearings (labelled C).

I know the IVA inspectors are hot on any play in steering components so decided that I had better investigate now before I refitted all the dashboard. I had theorised in my head that the lower bearing might be worn or the thrust washer might be missing.

Here's a useful Ford diagram I found on line....

Ford Sierra Steering column Ford Sierra Steering column by Sabrebuilder, on Flickr

So I removed the upper outer column which is just two bolts and I immediately saw the problem. The lower thrust washer (labelled B) was the wrong way round.

I swapped it over, bolted it back up and fitted the steering wheel. Problem gone completely with no perceptual play. I must have assembled it incorrectly about 8 years ago when I cleaned and painted the column.

I feel a bit of a dummy for doing this but really glad I found it now before the IVA test!!

More progress to report tomorrow....

Stay safe, Peter

|

26th June 2021, 20:19

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Sometime the simplest jobs....

Sometime the simplest jobs....

Thanks to Jack and Mick for your kind comments on last weeks update.

-----------------------------------------------------------------------

I'm trying to complete two tasks per week and this weeks tasks looked like some easy wins.

My list simply said "recover windscreen trim and fit Interior light and mirror" what could be simpler?

First, I had to push the car out of my garage to access the loft above and the car is certainly getting heavier with so much now fitted. Luckily, the windscreen trim pieces were in the box that I packed them in 8 years ago! And on first sight didn't look to bad.....

Windscreen trim Windscreen trim by Sabrebuilder, on Flickr

Windscreen trim Windscreen trim by Sabrebuilder, on Flickr

But when I started to strip of the old covering I found the rain had soaked into the foam backing and rusted the metal former.....

Windscreen trim Windscreen trim by Sabrebuilder, on Flickr

Windscreen trim Windscreen trim by Sabrebuilder, on Flickr

So I first stripped of any remaining paint and glue with some paint stripper. I then coated it in some de-rust gel to remove most of the rust and after that sanded it smooth. A coat of rust converter and then some new black paint restored it back to almost new condition.

Then it was recovered with some new foam and cream vinyl. I then trail fitted the interior light and mirror before refitting to the car.

Windscreen trim Windscreen trim by Sabrebuilder, on Flickr

Having connected up the interior light I decided to test it by connecting the battery. As I reconnected the battery there was a spark and a small pop sound. Hmmmmmmm

I checked the main fuse panel and sure enough Fuse 2 had blown which is the supply to the courtesy lights. The interior light has three connections Earth, Perm supply and switch supply. The colours of the wires match the Sabre loom so I just connected them up.

Interior light Interior light by Sabrebuilder, on Flickr

It has three wires because like most interior lights it has a little slide switch which over rides the door switches. After a bit of head scratching and studying the switch I realised it was designed for a 'switched earth' circuit but the Sabre loom is a 'switched live' circuit. (This was my scribble on the bench)

Interior light connections Interior light connections by Sabrebuilder, on Flickr

The simple solution was to swap to 'switched live' by swapping the purple (permeant supply) and the black (earth) wires. The wires are soldered to the light fitting so quite easy to de-solder and swap the wires over.

Finally, I could screw it all back in position....

Interior light and mirror Interior light and mirror by Sabrebuilder, on Flickr

So I got my tasks done this week but it took much more time than expected but it's all part of the fun

Until next week, stay safe, Peter

Last edited by peterux; 26th June 2021 at 20:23..

Reason: typo

|

13th July 2021, 21:01

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Doors, locks and latches.....

Doors, locks and latches.....

For once my lack of updates is because I've been very busy in my garage. I finally decided to tackle the re-assembly of the doors. The original builder had made a start on the doors but I don't think they were ever finished as the locks didn't work and the electric windows weren't wired up.

For those of you not familiar with the Royale Sabre, the doors are a complex GRP moulding with an internal steel support frame. Working on the door locks is like key hole surgery and a pair of very long nose pliers are essential.

Drivers door Drivers door by Sabrebuilder, on Flickr

One of the benefits of my build being over an extended period  , I've been able to accumulate new latches, exterior handles and internal handles. The doors are designed to use either Ford Sierra or Ford Granada locks and handles. I'm using Sierra latches and Granada handles as these are nice chrome versions of the cheaper black plastic Sierra ones. It's a bit of an adventure as the build manual leaves little detail on how the latches and handles should be assembled.

The locks are fiendishly complicated to understand how they operate and I hoped it would become clearer once they are connected.

Drivers door lock1 Drivers door lock1 by Sabrebuilder, on Flickr

The tab on the left with the red clip is for the external key lock. The other left tab with the yellow clip is for the external handle. The tabs on the right are for the internal handle and lock. Ford designed them with a primitive central locking system but I have decided not to use this for a number of reasons and I figured that on a two door car it wasn't really a problem.

I manged to source new locks from Germany.

Drivers door lock2 Drivers door lock2 by Sabrebuilder, on Flickr

The Royale build manual advises that it's not possible to use the original Ford lock barrels as the GRP doors are thicker than the Sierra steel door skins. The ones that came fitted to the car are very rusty so I bought these off a stall at Stoneleigh. The tab is far too large and had to be modified.

Lock barrel 2 Lock barrel 2 by Sabrebuilder, on Flickr

The Ford lock 'red tab' has a total travel of only18mm so I had to create something that translates 180 degree rotation to a 18mm travel. This is the third option that I came up with and seems to work. The small bush in the centre is welded to the tab but is a bit rough as I had the welder turned up too high. The washers at the base are Araldited on just to hold them in place while the 5mm countersunk screw is tightened.

Drivers door lock adapter Drivers door lock adapter by Sabrebuilder, on Flickr

With the key lock and adapter in place I then had to bend up an operating rod to connect the two. Here it is shown in the locked and unlocked position.

Drivers door lock rod 2 Drivers door lock rod 2 by Sabrebuilder, on Flickr  Drivers door lock rod 1 Drivers door lock rod 1 by Sabrebuilder, on Flickr

Rotate the key and it is in the locked position. The metal bar in the middle is part of the steel internal door frame. Bending and shaping the rods is a very tedious and frustrating job with much cursing.

Next, I fitted the exterior handle....

Exterior Locks Exterior Locks by Sabrebuilder, on Flickr

And then bend up another rod to connect the extrior handle to the latch mechanism. The original Ford rod turned out to be the right length but the wrong shape so with more bending and more cursing...

Outside handle actuator rod 1 Outside handle actuator rod 1 by Sabrebuilder, on Flickr

Outside handle actuator rod 2 Outside handle actuator rod 2 by Sabrebuilder, on Flickr

So now I had an external key barrel lock and handle that seemed to work so I moved on the fit the interior handle....

The original builder had used the Sierra handles but I wanted to use Granada chrome handles.

Interior door handles Interior door handles by Sabrebuilder, on Flickr

It soon became obvious that I need to fit the door card to get the position and height of these handles correct. Here's the GRP door card being fitted to align the interior door handle.

Door card Door card by Sabrebuilder, on Flickr

I've fixed the interior door handle with these two strips of galvanised steel.

Interior handle fixing 1 Interior handle fixing 1 by Sabrebuilder, on Flickr

And then make up another actuating rod from the handle to the latch....

NOTE: the following fitting is incorrect. Please see Post #538 below for the correct fitting.

Interior handle actuator rod Interior handle actuator rod by Sabrebuilder, on Flickr

Which had to be supported half way along with one of the original Ford clips.

Interior handle actuator rod Interior handle actuator rod by Sabrebuilder, on Flickr

At this point I decided not to fit the actuator rod for the internal lock as with a soft top car this would be a security risk. It would be easy to put a wire or stick between the top and window and flick the lock off.

But now I was stuck as the logic of the Ford latch mechanism didn't work.

To cut a long story short I found adding a spring in place of the interior lock appears to work.

Interior handle actuator rod Interior handle actuator rod by Sabrebuilder, on Flickr

The spring allows the fourth operating leaver on the latch to be moved when unlocking with the key and pulls it back to the locked position when the key is moved to the locked position.

Difficult to put it into words but it appears to work.

This has to have been the most frustrating part of the build but I feel I'm nearly there.

Of course, I've still got to tackle the electric windows but I may do the locks on the passenger door while I can remember how I did it!

So until the next update, stay safe........

Peter

Last edited by peterux; 28th September 2021 at 16:57..

Reason: Incorrect interior handle control rod fitting

|

14th July 2021, 08:33

|

|

Senior Member

Enthusiast

|

|

Join Date: Sep 2004

Posts: 1,892

|

|

That must be the most complicated door of any kit car! And the fibreglass mouldings are amazing. I wonder if they were made from a mould taken from a "real" steel door? If not they must have taken many many many hours to design and make.

Looking forward to seeing the end result!

Cheers Robin

|

15th July 2021, 19:49

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Quote:

Originally Posted by MartinClan

That must be the most complicated door of any kit car! And the fibreglass mouldings are amazing. I wonder if they were made from a mould taken from a "real" steel door? If not they must have taken many many many hours to design and make.

Looking forward to seeing the end result!

Cheers Robin

|

Yes, it surely is. It doesn't look exactly like any Sierra doors I've seen on line but I'm guessing that this must have been the starting point. Perhaps they modified a steel door and then took a mould?

As you say, the amount of work creating all the drawings, jigs, tooling and moulds for the Sabre must have been a huge project. John Barlow (the designer) must have envisaged selling a much higher number of kits than the 150 that were made. Even the door cards are a custom moulded GRP part. |

25th July 2021, 19:51

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Not a huge amount of progress since my last update but I have now fitted the grab handle to the drivers door.

The grab handles are screwed to a threaded plate that sits behind the door's inner skin. But the grab handles and securing plates were missing from my car, presumably lost somewhere along the way?

As the grab handle support plates were missing , I made some up from 4x35mm bar simply because this is what I had in my stash. The outer two holes are threaded to take 5mm fixing screws and the two inner holes are to fix the plate to the door inner door skin.

Grab handle and support bar Grab handle and support bar by Sabrebuilder, on Flickr

You then fix the door trim panel in place and drill the holes through the trim panel and inner door skin to get the holes aligned.

The support plate is then pop rivetted to the inside of the inner door panel. The pop rivets are just to hold the plate in place until the fixing screws are done up. A very neat solution.

Grab handle fixing Grab handle fixing by Sabrebuilder, on Flickr

The keen eyed might notice that the self tapping screws I used to fix the inner handle have now been replaced with M4 nuts and bolts. The original builder had used self tappers but the RMC build manual says to use nuts and bolts and who am I to argue with John Barlow!

I've started fitting the locks to the passenger door now, so no updates for a while...

Until then, stay safe,

Peter

|

31st July 2021, 21:09

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Taking a break from working on the door locks and latches I decided to refit the dashboard surround which I haven't done since recovering it.

I then discovered that the heater demist pipes fouled against the body tub just below the windscreen. A quick check in the build manual confirmed that these should have been fixed at 45 degrees.

I had to remove them and refit correctly like this...

Demister vent connection hose Demister vent connection hose by Sabrebuilder, on Flickr

Then I was able to refit the surround and dashboard....

Dashboard and surround Dashboard and surround by Sabrebuilder, on Flickr

And just for future reference this is the surround's centre mounting fixing.

Dashboard surround support fixing Dashboard surround support fixing by Sabrebuilder, on Flickr

Once the steering column controls wiring is securred I can then test it all again

Until then, stay safe.........

Peter |

23rd August 2021, 08:43

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Not much progress in August due to grandchildren school holidays, days out and a short holiday.

But I did have some garage time yesterday and fitted and tested the windscreen wipers. The dashboard and steering column switches are all back in so I was able to give the engine a good run and I was pleased to find it started first try.

When I first installed the wiper system I had no windscreen so was not able to fit and test the arms and blades.

I started with the usual safe test with drinking straws to check the sweep angles looked ok.

(You will have to click on the picture to see the video clip)

Windscreen wipers 2 Windscreen wipers 2 by Sabrebuilder, on Flickr

That looked okay so I proceeded to fit the arms and blades. The arms need to be shortened and the crank angle tweaked to get the blades close to the windscreen lower edge. I started with the far left wiper arm and worked my way across.

Wndscreen wipers 1 Wndscreen wipers 1 by Sabrebuilder, on Flickr

Despite all the rain yesterday I was testing inside with a bottle spray so the real test will be in the real rain :-)

Progress will be slow over the next few weeks so that's all for now,

stay safe,

Peter

|

12th September 2021, 20:53

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Okay, so here's a quick update of what I've been up to in my garage....

Apart from the pull handle fixing, I've finished the locks on the passenger door.

(Glad that's over as it's the fiddliest of jobs)

Passenger door Passenger door by Sabrebuilder, on Flickr

The cut out for the passenger door latch had been poorly cut so I had to fill it, reshape it and paint it before installing the Ford latch. I had sourced some brand new Ford fixing screws but they were too short due to the thickness of the GRP. But I found some yellow passivated Torx screws on ebay that look professional. I also bought some matching yellow passivated bolts for the door crash protection bars fixing.

Door latch Door latch by Sabrebuilder, on Flickr

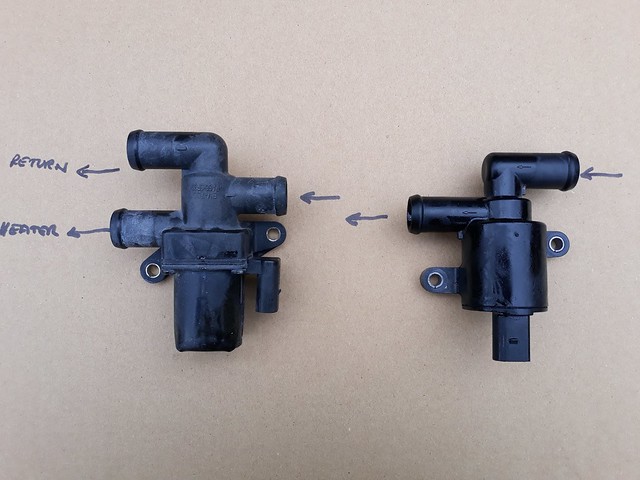

When I first installed the engine I used a two port heater valve between the engine and the Sierra heater matrix.

It dawned on me one day that this was a potentially a big mistake as it means the coolant doesn't circulate through the BMW M52 cylinder head when the heater valve is closed. Whilst looking for a solution on ebay I came across a VW/Audi three port valve that was similar to the two port valve I used initially.

Heater valve comparison Heater valve comparison by Sabrebuilder, on Flickr

Luckily, the new three port valve is almost identical in size to the original, the same mounting hole dimensions and has the same electrical connector, making it a relative easy swap.

New heater two way valve New heater two way valve by Sabrebuilder, on Flickr

Here's the new valve installed. The main work was re-routing the hoses and adding an additional return flow hose for when the valve is shut.

New two way valve installed New two way valve installed by Sabrebuilder, on Flickr

Hose work complete. The air vent had to be repositioned due to lack of space.

New heater valve installation New heater valve installation by Sabrebuilder, on Flickr

I've wired up this temporary switch to control the heater control valve. Testing confirmed that I can now switch the coolant on and off through the heater matrix.

Temporary heater control switch Temporary heater control switch by Sabrebuilder, on Flickr

That's all for now........

....peter

|

28th September 2021, 16:54

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

I'm now back working on the doors again......

The next job on the list is to refit the door windows and their electric winding mechanisms.

I started by refitting the window channels and some new velvet covered rubber channel runners. I then trial fitted the window glass and quickly discovered that it clashed with interior handle control rod. It was then that I realised the control rod has to be fitted above the inner door skin (i.e. between the inner door skin and the door trim panel). At first this looked like a lot of re-work but I manged to rebend the existing rod and cut a new slot for the supporting clip.

This is how it is supposed to be fitted....

Internal handle control rod Internal handle control rod by Sabrebuilder, on Flickr

A couple of hours of knuckle scrapping and it was re-fitted correctly.

Also, potentially fouling on the window glass was the nut and bolt I fitted to stop the lateral movement of the handle. The new arrangement consists of an aluminium strip bolted to the handle and then fixed to the inner skin well away from the window glass.

Internal handle fixing Internal handle fixing by Sabrebuilder, on Flickr

The window glass now slides up and down smoothly, without any issues.

I'm now working on fitting the weather strip but I also need to fit the chrome strip and the wing mirror as you can't get to the fixing nuts of these once the glass is in place.

Until next time, stay safe..........

............peter

|

8th October 2021, 19:03

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

Work continues on my the doors for my Royale Sabre.....

The original chrome decorative trims are badly corroded and didn't shine up when polished with chrome polish.

When I bought the unfinished Sabre it came with an incomplete set of new trims. I have decided to use the new trims on the doors but they had the remains of the welded on connections for the chrome plating process. It took me a good few hours with a 'dremel' type grinding wheel and a set of needle files to remove all the debris.

Door Chrome decorative trim Door Chrome decorative trim by Sabrebuilder, on Flickr

Door Chrome decorative trim Door Chrome decorative trim by Sabrebuilder, on Flickr

The original chrome strips had fixing studs welded or maybe braised to the strip.

The new strips have a slot but no fixings in the box.

Whilst looking for a solution, I found that if I shaved the top off a m4 button head screw it would slide into the slot but would rotate when you tried to tighten them. So I got some flange head stainless steel screws and by shaving the head and then grinding off two parallel edges these homemade fixings slide into the slot but don't rotate when tightened. It took me about an hour to make 8 fixings.

Chrome trim fixing Chrome trim fixing by Sabrebuilder, on Flickr

Here's the first chrome strip now fixed in place.....

Door Chrome decorative trim Door Chrome decorative trim by Sabrebuilder, on Flickr

Moving on, I next tackled the mounting of the 'wing' mirrors.

I'm using Tex 'e' approved wing mirrors to avoid any issues at the IVA test. I had to profile the back of plinth to match the curvature of the door.

Nothing seems simple on these doors!

Wing mirror mounting plinth Wing mirror mounting plinth by Sabrebuilder, on Flickr

I refitted the window channels and trimmed the new flocked rubber window channels to the door top profile. Filing out the top of the doors to match the shape of the channels is another tedious time consuming process.

I then moved on to fitting the window glass weather strip....

The weatherstrip was cut to size, trimmed at the ends to fit over the channels and then fixed to the door with small self tapping screws along it's edge. (poor photo warning..)

Door window weatherstrip Door window weatherstrip by Sabrebuilder, on Flickr

I'm now moving on to re-installing the electric lift mechanism and windows....

Until next update, stay safe........

...peter

|

15th October 2021, 19:36

|

|

Senior Member

Enthusiast

|

|

Join Date: Mar 2005

Posts: 3,077

|

|

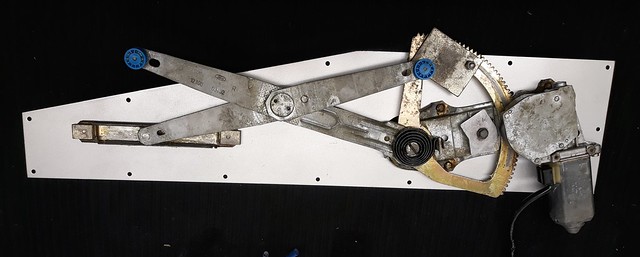

So, next up is the re-installation of the window lift mechanisms and windows.

First, I washed out all the old grease and generally cleaned up the mechanisms. I then re-greased all bearings and gears. The original builder had already modified the mechanisms with the new upper stop plate and removed the lower stop plastic insert as per the build manual. I then fitted new plastic wheels (thanks, Mike) and liberally coated the wheels and the runners with new grease.

Window winder mechanism installation Window winder mechanism installation by Sabrebuilder, on Flickr

Then, following the build manual instructions I fitted them to the door and windows. The instructions worked fine for the drivers door but for the passenger door I couldn't get the wheels on to the window runners. I ended up dismantling the mechanism from the plate, fitted its wheels to the window runners and then installed the plate afterwards. Not easy but it is just possible to install it this way.

Window down.......

Window fitted - down Window fitted - down by Sabrebuilder, on Flickr

Window up............

Window fitted - up Window fitted - up by Sabrebuilder, on Flickr

Both mechanisms work fine and appear to stop at the right places although I won't know that for certain until the doors are re-hung on the car.

All was fine until I realised that I had forgotten to fit the chrome strip to the passenger door

All I can say is it's quicker when you've done it before

Until next time, stay safe........

.......peter

|

|

Currently Active Users Viewing This Thread: 20 (0 members and 20 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 17:11.

|