|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

30th October 2015, 06:25

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

Long time since I've been on so it's brilliant to see that the shell is finally getting bonded on!

It's the homeward stretch now, so based on the build so-far, what's that, another 2, poss 3 years? ;-)

Just kidding matey, it's looking really good and fingers crossed you'll be on the road come the spring just in time for the next round of shows and run-outs  |

30th October 2015, 06:53

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Ed, Roadster, Mike, Pops & Dave - Thanks chaps.

I am sure there will be a few bumps along the road to the finish line, but this is still a real turning point.

The simple fact is that my body shell will always be a bit "wonky", so I just need to embrace this and carry on.

Finally, my wife was certainly happy to hear that she would never have to help me lift the body shell again.

Cheers, Paul.

|

30th October 2015, 18:46

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Just a little bit ...

Well it looks like I got the timing just right yesterday, as it has been wet ever since I put the covers on.

Thankfully, the weather finally cleared up this afternoon, so I could make a bit more progress...

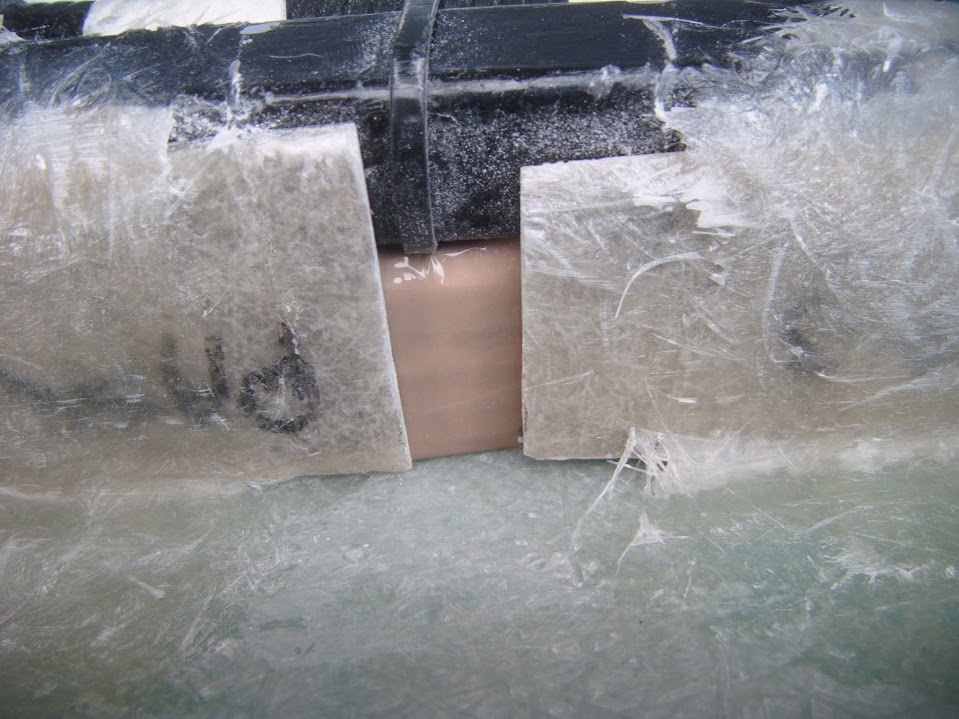

I clamped the sides of the body shell to the lowest part of the framework to hold it in place.

( The areas in front of the rear wheel arches have a tendency to flare out a bit. )

Whilst the clamps did a great job of pulling the sides of the body shell in, this meant my "bridges" were now too deep.

So what I should have done was clamp the side in before I made the templates.

Still, nothing a quick session with the angle grinder couldn't sort out.

I also cut out two small sections of fibreglass to match templates I made to bridge the gap between the Spitfire arches and the body shell.

I also cut out two sections of plywood to start the process of sealing the boot floor to the body shell.

( I think this will be easier to do in smaller sections, rather than one big piece. )

Then I quickly painted/treated the freshly cut edges, so they will be ready to fit tomorrow.

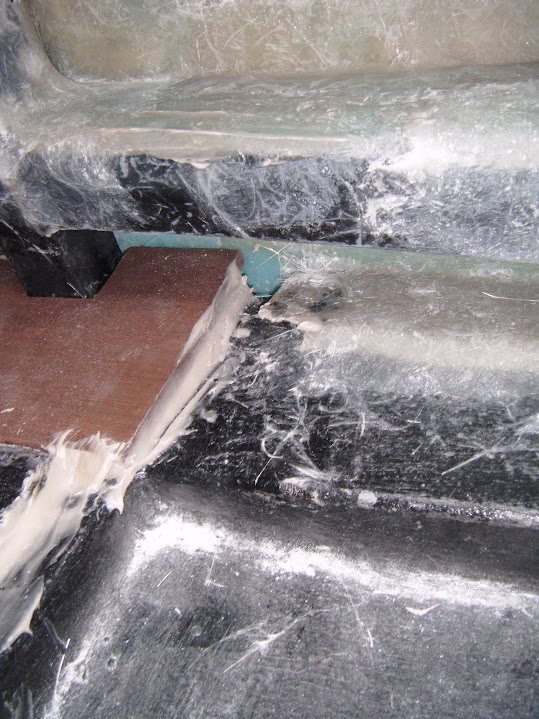

Then I taped the adjusted bridges to both the floor join and the "top" join on both sides.

( The tie down straps are currently connected to the "middle" section of framework. )

Finally I taped the bridges to the wheel arches.

Note:

I haven't decided the best way to completely seal off this gap, but these small pieces should hold the body shell in position.

I then added the first few layers of fibreglass matting to all the pieces on the passenger side.

I was just cleaning the brush in preparation for starting on the driver's side when it started raining.

Luckily, I was able to tidy everything up and get the covers on before it came down too hard, but no photos.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

The early end to car work, meant a change of plans and I took one of my daughters to the latest Bond film.

You really can't beat seeing a Bond film on the big screen and I'll be humming the theme tune for the rest of the day.

Until next time, take care, Paul.

|

30th October 2015, 19:10

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Nice to see that body get bonded on, it really is a milestone and marks a turning point in a Sammio build as it means the majority of the time consuming work is now finished. From memory, the car will seem to come together and finish itself really fast now, so long as you put the work in...

Oh, and don't get hung up on the wonky bodyshell thing, all Sammios have some wonk to them, it's called character and nobody but you will ever even notice.

Now lets have yours finished by next spring so we can go out for an Easter drive together.  |

31st October 2015, 15:13

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mr T - Cheers.

As always, I know you are right about the "wonky" nature of Sammios being part of their character / charm.

Thankfully, I can now see enough of the finished car to know it will still look like an old racing car with a bit of "history".

Finally, the thought of going for a drive with you (+ Phil & Barry) "sometime" in 2016 will keep me going through the Winter.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Happy Halloween!

Started the day by taking a deep breath before removing all the tie down straps holding the body shell in place.

( Note: The rear end is still sitting "high" on blocks.)

Thankfully, I then resisted the temptation to apply a HUGE level of brute force and ignorance to "test" the bond.

Instead, I merely gave the body shell a few gentle nudges to confirm is it definitely stuck to the Moon Rover.

Then I rearranged the tie down straps to hold down the rear passenger corner.

I also replaced the clamps on the driver's side, as yesterday's fibreglass session was enough to hold the passenger side in place.

I made templates for the first of the support panels to go inside the boot area.

Which were then cut out of plywood and the fresh edges were painted / treated.

I added some support under the gaps on the passenger side's "top" bridge.

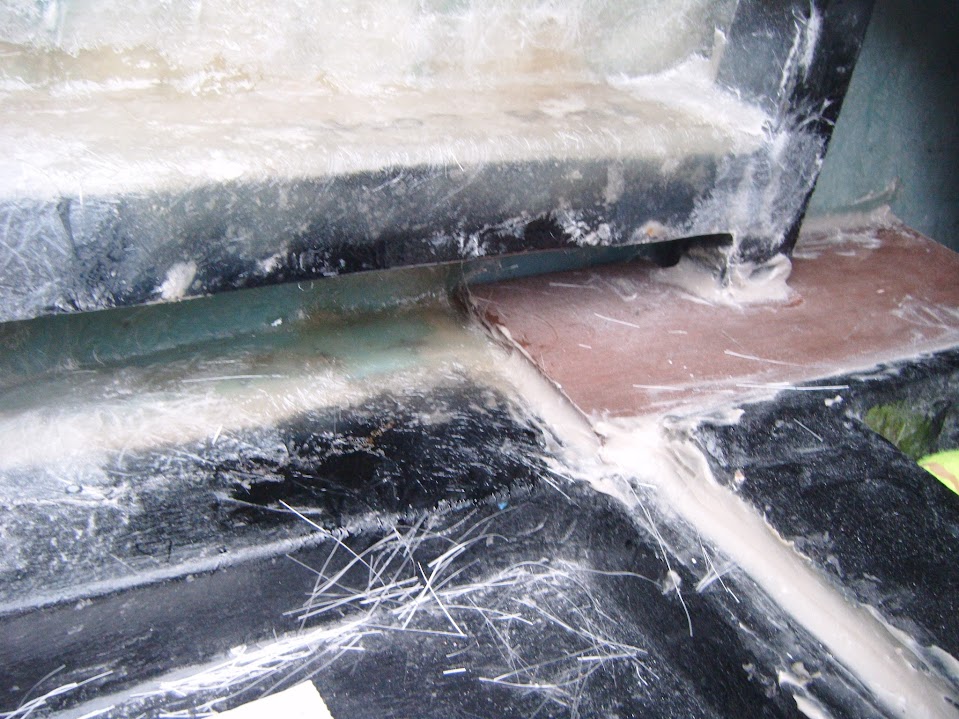

The first fibreglass session added the first round of matting to the driver's side.

The second session added the second round of matting to the "top" & "floor" bridges on the passenger side.

Plus the first round of matting on the "middle" bridge, which could be fixed in place now the tie down straps were removed.

I then put the cockpit cover on and left that all to set.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

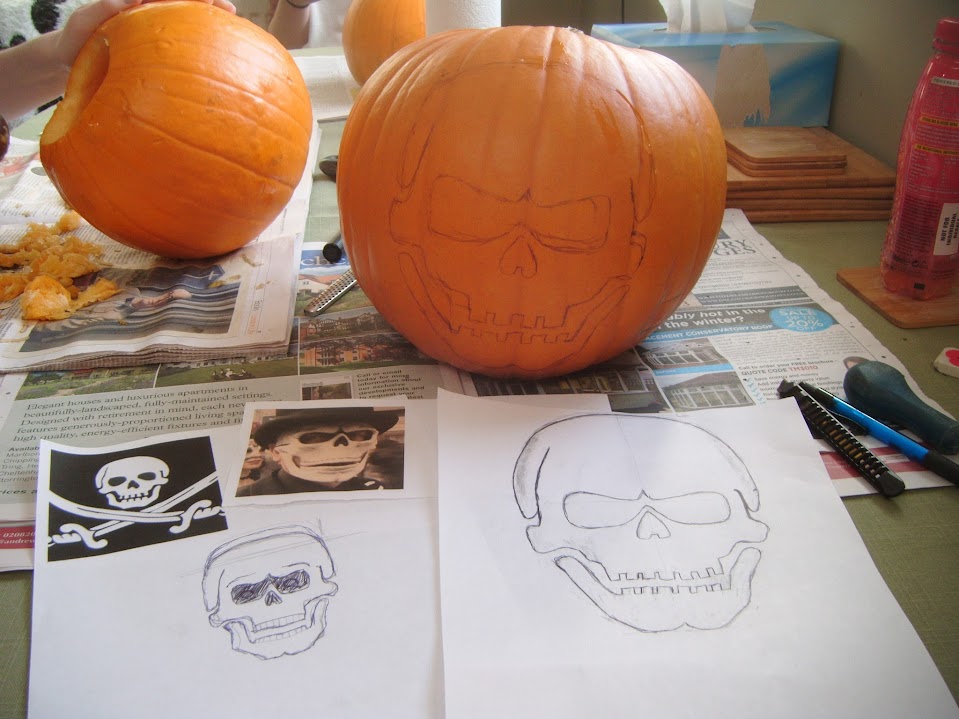

As it was now time to turn my attentions to the most important job of the day...

Carving pumpkins with my daughters.

This year I attempted to cross the death mask from the latest Bond film with a Pirate skull.

Obviously this was easier said than done, but I got there in the end.

And the complete family line up.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I've now packed the car up for the night and even though there is more fibreglass matting to add, it all feels very solid.

Until next time, take care, Paul.

|

1st November 2015, 15:50

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Sunday Service:

After the morning fog had finally cleared, I cut out another section of left over fibreglass.

Which will form part of the join between the boot floor and the body shell here.

( Passenger side. )

Note:

At this point I just want to ensure the rear passenger corner is supported/held in place.

Then mixed up some more bonding paste and tackled a number of small jobs.

Fitted the plywood panels inside the boot.

Fitted the panels between the boot floor and the rear body shell at the back.

Not great photos, but added paste where the boot lid rain channel meets the framework.

And finally the section I had cut out earlier.

Boy was this messy work and not helped by the need to crawl around on my back to reach some of these areas.

The only other thing I had time for today was to add more fibreglass matting to all three "bridges" on the driver's side.

I will be adding at least one more layer of matting along all the joins at some point, but it already feels very strong.

Until next time, take care, Paul.

|

3rd November 2015, 16:50

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Busy Bee:

Unfortunately, I've been very busy with non car stuff recently, but I did manage a little bit today before it got dark...

Checked the panels that were bonded in at the weekend and they all feel pretty solid.

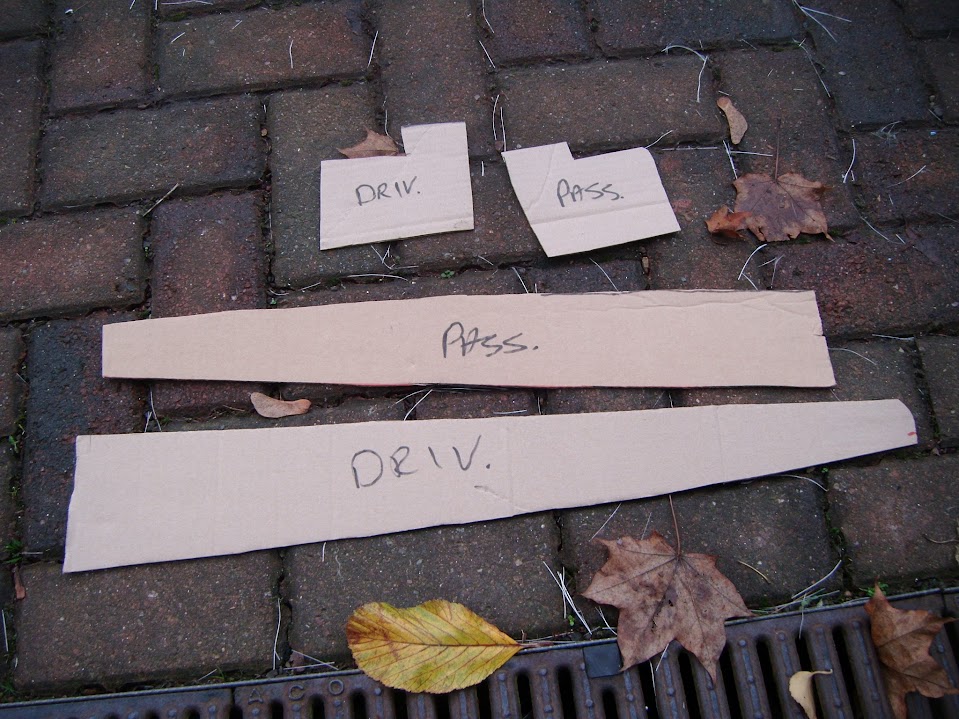

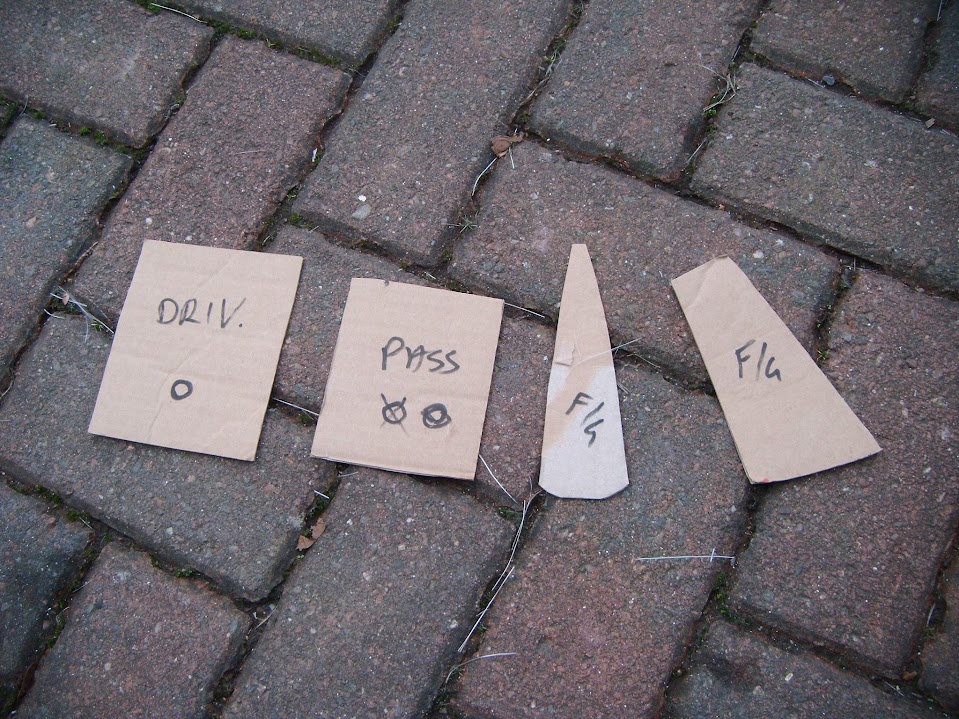

Then made some more templates for the next series of panels I need to fit.

( I had made the passenger floor one before, but it needed a trim to match the "pulled in" body shell sides. )

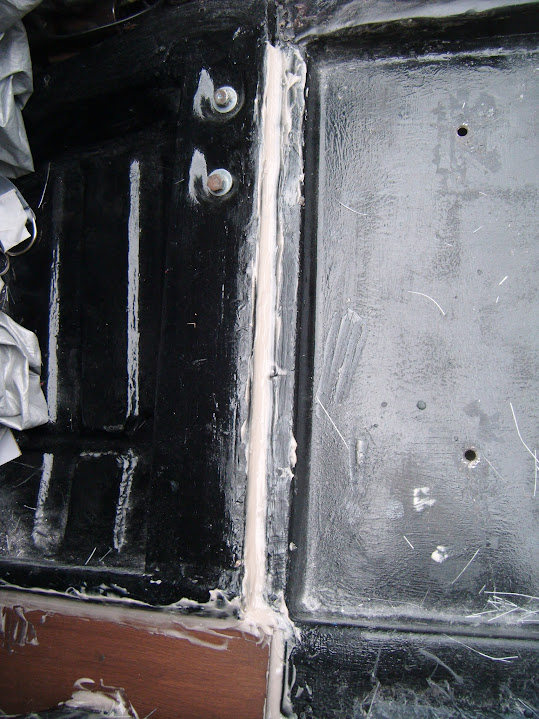

I thought a simple (and quick) job would be to use some Tiger Seal at the front end of the body shell.

These photos are not great, but there is a thin gap between the bulkhead and the body shell on the engine bay side.

As well as along the dash board side.

Unfortunately, the cheap and cheerful sealant gun I bought, turned out to be cheap and nasty.

Once the handle collapsed/imploded, it was just not possible to push the sealant out.

So I've ordered a "proper" heavy duty one and will have to come back to that job another day.

I just had time to cut out the next batch of panels from plywood and fibreglass.

But I want to test fit both of the cockpit floor panels before I paint/treat the edges.

( As they may need a fit of fine tuning to get a good fit. )

So that is another job that will have to wait.

Until next time, take care, Paul.

|

4th November 2015, 17:40

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Wet Wednesday:

Typical, I had some car time available this morning and it was chucking it down outside.

However, I must remember that now is the time for a "seasonal" adjustment to my expectations.

As the simple reality is that the weather plays a much bigger role during the Winter months.

I did spend a bit of time tidying up the Summer House, as I also needed to look for something for my daughter.

Then in my second "typical" moment of the day, I didn't find what I was looking for, but I did find this in an old box.

Yes, a sealant gun, just like the one I ordered yesterday, that I had clearly forgotten I even had.

Eventually it stopped raining, so I took the covers off and started to test fit the cockpit floor panels.

But no sooner had I started, when the rain returned.

So I quickly threw the tarpaulin over the top.

Then carried on adjusting the panels in the porch.

And getting a bit wet every time I went out to check the fit.

By the time the rain had finished, the panels were ready.

Passenger side (before & after):

Driver's side:

I did use the sealant gun to apply the Tiger Seal into the gaps on either side of the bulkhead join.

Unfortunately, it was just too grey outside to get any decent photos, so I'll try again another day.

Then it was back to making cardboard templates for more plywood panels to support the body shell.

The area between the two humps is very secure, but there is "thin air" under the rear cockpit corners.

So I will be adding two panels between the frame and the body shell here:

I will also add a small panel between the top of the Spitfire wheel arches and the underside of the body shell arch.

I couldn't get a decent photo of the panel in position, but it will be somewhere around here.

The next thing I looked at was how the cockpit sides will work as there isn't much room to play with.

On the passenger side, a panel starting from the "middle" framework would reach.

But if I started the panel at the floor, the plywood would stick out beyond the edge of the cockpit.

Which is what would happen no matter where I start on the driver's side.

So on this side, I will add a panel along the top frame rail underneath the sides.

( I may actually do something similar to this on the passenger side. )

Note:

My current concern is how to support the sides of the cockpit, not the whole cockpit panelling.

( Which will still need to be done for the "look" of the car, rather than its internal strength. )

At some point I will need to add the cockpit "return" edge along both sides of the cockpit too.

But for now I cut out the pieces needed to support the rear of the cockpit.

I also cut out another section of fibreglass to extend the "top" bridge on the driver's side.

Finally, I painted/treated all the edges of the plywood panels in preparation for bonding them into place.

This panelling work is quite time consuming, but it is worth spending the time to ensure I have a solid car.

So it still feels like I am moving forwards with the build, albeit quite slowly.

Until next time, take care, Paul.

|

5th November 2015, 12:57

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

I fought the rain, and the rain won.

The forecast gave me hope that I could get a few hours on the car this morning, but it was not to be...

Although while it was still raining I gave the plywood panels another coat of paint inside the Summer House.

When it stopped, I moved everything I needed to the porch, but the rain kept returning when I stepped outside.

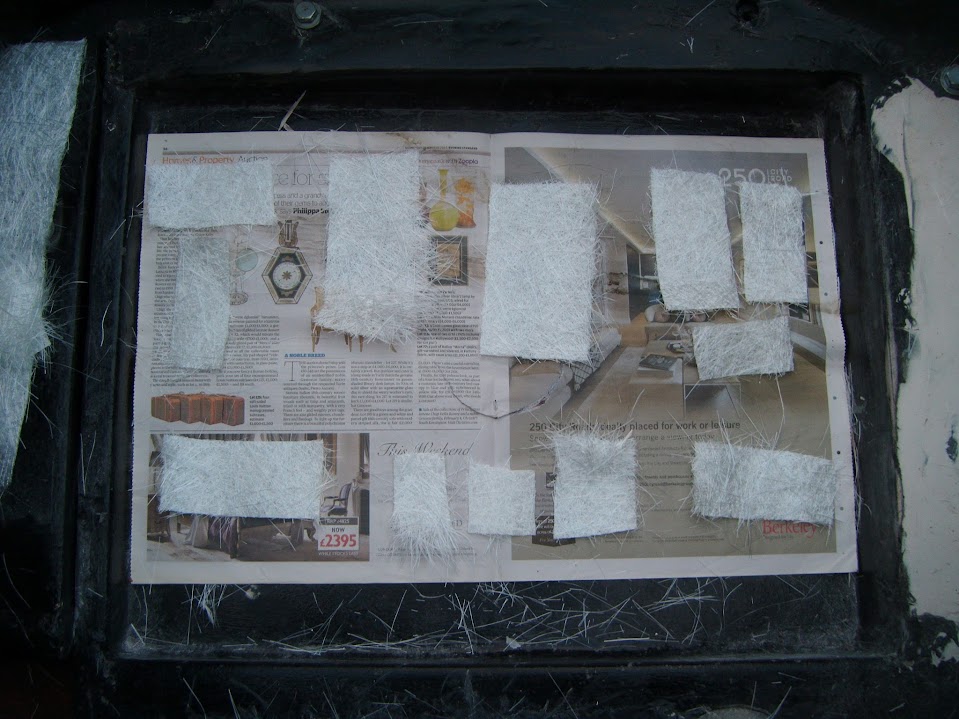

Eventually it was dry enough to make a start and I cut out all the fibreglass matting I needed.

But by the time I'd finished working on the driver's side the rain had returned again.

Still, at least I managed to get the "top" bridge extension piece in place, plus some extra layers on the other levels too.

Unfortunately, it looks like it will continue raining for a couple of days.

So until next time, whenever that is, take care, Paul.

|

5th November 2015, 20:13

|

|

Senior Member

|

|

Join Date: Apr 2014

Posts: 198

|

|

Hi Paul, Can't you adopt the gazebo up on the front while there are no ladies in the house then hide it in the summer house before they return approach, shhhhhh its s secret. Ed.

|

6th November 2015, 06:57

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Ed - Unfortunately, my "Circus Tent" needs at least 2 people (& ideally 4) to put up.

Although my main concern with using it during the Winter is the wind.

The weird thing is that even though the rain is stopping play at the moment, I generally get a lot done over the Winter.

Thankfully, I can do the internal panelling work in small stages and it still feels like progress.

Cheers, Paul.

|

7th November 2015, 16:54

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

You know a few of us may have mentioned once or twice that you do tend to over-think solutions.....

Even if we do say that, I must admit that I do like how you solve these build problems and your panelling is progressing really nicely  |

7th November 2015, 17:24

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Dave - Guilty as charged m'lud.

Funnily enough, I was actually think along those lines very recently.

As it dawned on me that I might be the only Sammio with a 3 level horizontal join at the sides.

Reading other builds, most people join the floors to the side and then go straight to the internal panels.

Although in my defence, I really can't align the internal panels in the traditional way due to a combination of "wonky" factors.

Still, despite the over engineering, I must confess that I really like how solid the body work feels.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Wet & Windy:

There was just brief chance to work outside late this afternoon.

I tried to take some more photos of the Tiger Seal joins on either side of the bulkhead, but they are still not great.

I had to use the lowered floor pans to lay out the fibreglass matting to keep it out of the wind.

Just before I started putting this lot in place the street lights came on.

So it was pretty dark by the time I'd finished, so the flash was required.

With a bit of luck, I will be able to bond the next round of panels in tomorrow.

Until then, take care, Paul.

|

8th November 2015, 14:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Remembrance Sunday:

Hard to believe we were actually at the Tower of London poppy field this time last year.

Anyway, I didn't want to be doing any car work during the 2 minute silence this year.

So I mixed up another batch of bonding paste and got to work early.

The cockpit floor panels went it.

I had to use a rock to hold the driver's side in place due to the angles involved.

Next I added the two small panels between the frame and the body shell on either side of the rear cockpit corners.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

After watching a bit of the Cenotaph service on TV, I went back out and did another round of bonding.

I added both the fibreglass panel and the plywood one to the passenger side at the rear of the body shell.

Before adding the plywood one to the driver's side.

Notes:

- At this point I've added more support to the passenger side as it is still held down by a tie down strap.

- The drain hoses for the boot lid rain channel will exit through the next panels to be fitted in between these two.

I also did the panels between the Spitfire rear arches and the body shell arches.

It was not easy to get a camera into this space, let alone get a decent photo, but hopefully this gives you the general idea.

( More paste will be added after this has initially set in position. )

I then used the last of the paste to start filling in the gaps between the bulkhead and rear framework.

Before:

After:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Later I returned outside expecting to add some more bonding paste, but there was a fine mist developing.

So it was back on with the covers and creating just a small area to work in.

But that was enough to cut out the next round of templates.

( 2 x cockpit side supports + 2 cockpit floor vertical panels )

Then with the car now covered up completely, I cut the panels out at the bottom of the garden.

Before giving them an extra coat of paint/wood preserve paint.

It is still misty here, so I am going to call that a day.

Until next time, take care, Paul.

|

9th November 2015, 18:42

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Close Enough:

Took another deep breath this morning and removed the strap holding the rear passenger corner down.

Thankfully even the small amount of panelling work I have done is still strong enough to hold everything in place.

However, the real scary moment was still to come as I decided to take the car off the blocks and see what it looked like.

But first I had to wash down the mess I'd made of the house wall.

One of the biggest benefits of bonding the body shell on is that I no longer need to leave enough space for it along the side of the Moon Rover.

As previously, this was all the space I had to work in along the driver's side.

Now that I've "pulled in" the sides of the body shell, you can really see how the bottom edges of the bonnet flare out.

Thankfully, nothing a Tek screw can't fix in the short term.

Obviously, in the long term, this section is being cut out and re-attached to the body shell.

Then I jacked the car up, removed the blocks of wood and then slowly lowered it back to the ground.

As I started to slowly push it forwards, I though the steering was very heavy.

Then it dawned on me that the steering lock was engaged.

So with the key in the ignition, I could steer it to the far side of my driveway to take some photos.

Normally, the front wall stops me getting any decent view of the driver's side.

So here are a few more.

Although it looks a bit more "slammed" at the back than I was expected, this is entirely my own fault.

As it recently dawned on me that I was meant to lift the driver's side at the back to keep things level.

( And NOT pull down the passenger side, which is what I actually did. )

Having said that, there is now the slightest hint of an Austin Healey about it.

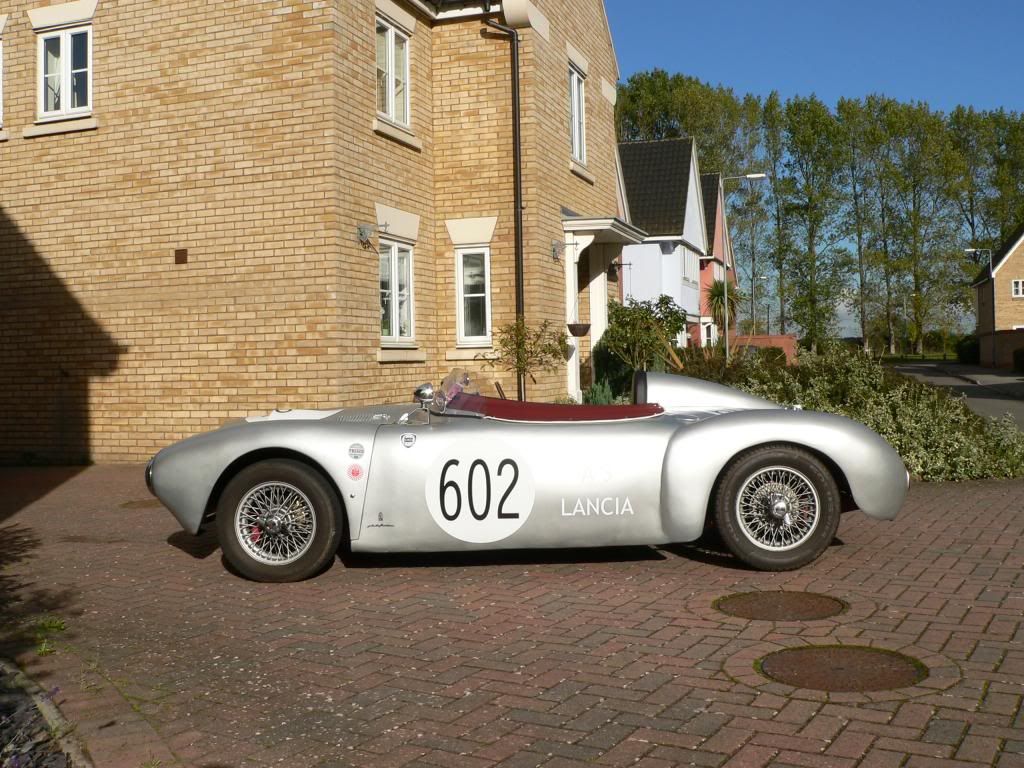

This is a photo Mister Towed posted on Mac's thread after seeing his two tone paint.

Which means, dare I say it, I might need to raise the driver's side rear arch profile a tad.

The passenger side needs a bit of work too, mainly around the leading edge.

In the absence of a drone to play with, I had to stick my head out of a first floor window to take this photo.

Make no mistake, I love the way this car is finally shaping up.

But the main reason I wanted to push the car forward was to check the real alignment "on the road".

( Although the angle of my sloping drive still causes me visual problems. )

I quickly put the rear lighting in place, to see if it lined up.

And this is the final view, and as the title of this post suggests, it is close enough.

End of Part 1...

|

9th November 2015, 18:43

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Monday - Part 2:

Well, after a lot of time spent cleaning the driveway & taking photos, it was time to do some work on it....

I cleaned up all the fibreglass along the sides of the body shell.

Because, with the cockpit floor panels in place, I needed to finish off the ends sections next to them.

A few layers of matting later.

It is also worth mentioning a "hole" I still have to fill in this area, due to the "angle iron" section of framework.

So I have made templates for small in-fill panels on both sides.

Next I mixed up some fibreglass filler to apply to the under side of the "bridges".

Although it is not easy to get a decent photo of the underside, but this is a section of the top bridge on the driver's side.

( Left of the photo is the side of the body shell & the right is where the bridge sits on the frame rail. )

Then it was time to bond in the plywood panels I cut the other day, starting with the vertical cockpit floor pieces.

Before:

After:

Then the supports for the cockpit sides went in.

I also made more templates for the next round of panelling between the boot floor and the rear body shell.

Finally, I loosened the rear wheel nuts to just finger tight.

Because at some point with the car jacked up, I will need to remove the wheels to get better access to the arches.

That was as far as I managed to get, due to other domestic chores, but a good day none the less.

So until next time, take care, Paul.

|

9th November 2015, 19:04

|

|

Senior Member

|

|

Join Date: Jun 2011

Posts: 935

|

|

Small amount of panelling??

Paul your car is super strong with the reinforcement going in.

It might even weigh the same as the donor.

Its looking good and it feels as if it transformed quite quickly after the hours of modding the bodywork.

By the time spring comes she will be ready for a cheeky run down the road.

|

9th November 2015, 19:17

|

|

Senior Member

Enthusiast

|

|

Join Date: Dec 2006

Posts: 1,130

|

|

Paul L, The car's looking good but, I wonder who will be the first person to bash their shins on the exhaust pipes sticking out the rear

|

10th November 2015, 07:06

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Roadster - Sorry, my poor choice of words, what I meant to say was ...

"Small amount of panelling in the rear passenger corner."

Given that I had to strap that corner down, I am genuinely surprised at how well the panel bonding works.

Which reminds me of this great quote about this phase of the build.

Quote:

Originally Posted by Mister Towed

...transforms the shell from wobbly blancmange to rigid structure...

|

It really does feel like each step I take now is a positive one, heading in the right direction.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Micky1Mo - Hopefully the fact the tail pipes are "shiny" will make them easier to spot.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Family Resemblance:

I spent a bit of last night looking back at yesterday's photos of the car & this one in particular.

Clearly my Frankenstein build approach means that my bulkhead is much higher than anyone else's.

Which in turn means the rear end will look much lower by comparison for that reason, regardless of how I bonded it on.

So I've trawled through the forum for some comparison photos of various Cordites/Navigators.

DonnySoutherner

Nellieb

Nellieb

AndyP57

AndyP57

Mac

Mac

Swifty

Swifty

Plus any excuse to post a photo of Mister Towed's Spyder.

( Note: He has fitted bigger tyres and tweaked the suspension since this was taken. )

Overall, once all my wheel arches have been re-profiled, I think the car will still be "part of the family".

Cheers, Paul.

|

10th November 2015, 17:14

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Access All Areas:

Had to do a bit of juggling to manage some time on the car today, but made a bit of progress.

I spent some time this morning thinking about the correct sequence required to seal off the cockpit.

As it is clear that some jobs need to be completed before other ones can be started.

E.g. I can't add the main panel for the cockpit sides, until the cockpit wall has been completed.

So I started by looking at the options for fitting the rear cockpit wall underneath the body shell.

Unfortunately, the end of one piece of box section is in the way a bit, but not the end of the world.

You may recall that there would be no room for the seats if I added the panel in front of the framework.

So my plan is to panel within the framework instead, as the body shell is already supported here.

After a lot of trial and error, this was the final template I ended up with.

If you look at the one for the driver's side, you will see it reaches out to the sides of the bodyshell.

Which is why I want these pieces in place before I butt the cockpit side panels up against them.

I think I will end up stealing another idea from Mr T's build for the curved corners.

Which will hopefully allow me to cover up any bits missed by the panel work.

But before the rear side panels can go in, I need to finish the cockpit floor underneath the seat belt mounts.

Looking in from above, you can see this is effectively another section of the bridge already added.

At this stage I'm also going to sort out the small in fill panels required for rear cockpit wall here.

Note:

The main rear cockpit panel will fit into the framework "triangle" above this section.

Which left me with a collection of templates to play with.

Some were cut out of fibreglass, including some pieces I made templates for the other day.

With the rear cockpit panels cut out of plywood.

Note:

You can just see the first rain drops appearing in this photo, so I couldn't test fit them.

Thankfully, I had already put the covers on the car before heading to the bottom of the garden.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

There wasn't much daylight left by the time the rain had eventually moved on.

I pulled out the spare wheel I rescued from a skip.

It has a higher profile tyre fitted compared to my wheel, so I plan to use as a guide for my arch profiles.

Note:

The wheel arches will be bigger than the outside of the tyre.

As it also dawned on me that I need to sort out these out before I can finish sealing off the rear cockpit area.

Next I wanted to check that all the panels fitted.

The fibreglass ones were OK (after a minor tweak here and there), but the plywood ones would not fit.

Unfortunately, there was just no way to angle them into position without one edge, or another, catching.

So I grabbed my jig saw and got to work.

Even after this drastic action, they both needed more minor adjustments before finally fitting.

Even though these will not be fitted for a while yet, I did paint/treat them.

There are still a lot of gaps to fill, I just need to double check to make sure I am not missing any.

Until next time, take care, Paul.

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 19:04.

|