|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

18th March 2015, 11:00

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

You made a good job of the rear lights Paul, it looks good and simple,

definitely a KISS effort!!

|

18th March 2015, 18:04

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - Thanks.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Another Odd Day - Part 1:

Spent quite a bit of time this morning looking at the boot lid in the vain hope a simple solution would present itself.

In the absence of any divine intervention, I started checking how much space I had to play with around the lid & bases.

As I will need to do some work to level both of these areas if the locking pins are ever going to work.

Next I made two cardboard templates for the bolt fixing areas.

As I want to use these to get the correct "level" at the base with some fibreglass filler underneath.

So I cut these out of metal and gave them a coat of etch primer.

While I had the primer out, I gave a quick coat to parts of the rear lighting area.

This rear view does give me a small glimmer of hope that one day this car will actually get finished one day.

However, this feel good factor quickly evaporated when I decided to add primer to a few spots on the boot lid while I was at it.

( As these re-shaped areas made the whole boot look at lot worse that it is. )

No sooner was the paint on when I remembered why I hadn't painted them before now, I clearly hadn't finished all the sanding down work.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

It was at this point I remembered I had a hospital appointment to get a mole checked out.

Thankfully I was given the all clear, but, just to be on the safe side, the mole was "zapped" with liquid nitrogen to kill it.

The mole was under my armpit, so whilst the first blast "smarted" a bit, the second blast made my eyes water!

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Eventually I was able to resume my battle with the boot lid.

I ground away the areas "above" the holes along the top edge of the lid.

This was to reduce the amount of "building up" I would need to do "below" the holes.

But no matter what I did, I still had problems trying to get everything to line up.

This work involves a lot of crawling underneath the body shell on a cold driveway & now I had a sore armpit too.

At which point, a mild burst of "boot rage" descended and I extended the holes in the mounting plates.

Thankfully I was able to calm myself down before I decided to take my angle grinder to the whole area.

End of Part 1...

|

18th March 2015, 18:07

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Another Odd Day - Part 2:

Not sure if it was the frustration, the cold, or the throbbing pain from the mole, but....

I finally had a idea about how to get everything to lie up, once & for all.

I dug out a length of old box section & drilled a hole in it.

Then after some careful alignment & measurement compared to the boot lid, I drilled a second hole & fitted my extra long bolts.

As if by magic I now had something that keeps the bolts parallel and correctly spaced.

My small spirit level suggested that the scuttle area between the aero screens was level(ish).

So this gave me something to compare both the lid and the bolt mounting areas to.

Clearly, the fact that the body shell slopes all over the places has not helped me find a straight line to work with.

Plus by initially trying to keep the bolts perpendicular to the boot lid, my design was always doomed to failure.

Still, at least now I really think this tool will allow me to set this up in stages, starting with getting the locking pins in level.

However, I definitely need a clear head before I start any of that work!

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

So I'll end with another couple of comparison photos.

I found this old photo of my very first attempt at mocking up the rear lighting layout.

( This was taken over 2 years & 4 months ago!  )

It was after all my "cut & shut" work that Oxford1360 called my car a "Wide Boy" Cordite.

And you can really see how much wider the car is now if you compare the photo above, with the latest view.

( Even after allowing for the narrower grouping of the lights. )

Only the reflectors have changed slightly, all the other lights & the number plate are the same size.

Note:

Since the first photo, the rear end has also picked up an extra aero hump, a boot opening & twin tail pipe cut outs.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I really hope that after another play with my new "bolt spacer" I will be able to sort the top locking pins out.

So until next time, take care, Paul.

|

18th March 2015, 18:12

|

|

Senior Member

Enthusiast

|

|

Join Date: Dec 2006

Posts: 1,130

|

|

Sorry Paul, but after following this thread for weeks I have only just realizes it was the actual boot hinges that was the problem

I have a spare set of 2CV door hinges. The same as I used on the G-46 doors.

If they were mounted on or under the rear edge of the body and boot lid, they would allow the lid to be opened past 90%, and you could put the locking handle between the humps.

They would also work on one side of the boot lid.

Any good to you as there are FOC.

Lights looking good!!! |

19th March 2015, 14:43

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Micky1Mo - Don't worry, I am sure a lot of what I write only makes sense to me.

Thanks for the offer of the hinges, but I'll hang on for now and give my "lift off" panel design one last chance.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Family First:

My eldest daughter was off school ill today, so she was my main priority and that is always OK by me.

Thankfully I was able to make good use of my time indoors by doing some Ebay shopping:

- All the stainless nuts & bolts required to fix all the lighting (front & rear) & rear number plate into position.

- More filler (normal, fibreglass & "stopper").

- More etch primer & some smooth black Hammerite.

- Some self adhesive heat shield matting to line the gearbox tunnel & protect the bonnet over the radiator cap.

However, my last bit of shopping took ages to find, because I was looking for the wrong thing.

I knew Mister Towed used small washers around his bonnet locking pins.

So I carefully measured the internal diameter of the BIG washers than my locking pins were supplied with.

The ID was 19 mm, so I "logically" looked for M19 washers, but without success.

It was only when I decided that I would have to get some M18 ones and file them out to the right size that I realised my error.

Yes, as I am sure everyone else knows, the ID of an M18 washer is actually 19mm.

In fact, the more I think about it, I am sure I have made this same mistake at least once before.

Anyway, at least this means that I now have some smaller 34mm wide washers on their way.

As a rough guide, the big ones in the photo above are around 65mm wide & the penny washers in the same photo are 40mm.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I did actually get a few chances to sneak out and play, but they were brief.

Still, something is always better than nothing, so here goes...

I put the rubber seal back on the boot rain channel to check the area I'd previously built up with filler.

This is my blurry "Before" photo:

And this is how it looks now, much better.

But I realised that I need to do the next round of work in the correct order to avoid messing it up.

I went back and had a look at the gap Swifty had around his boot lit.

Then compared that with what I have today.

So the first job is to get the boot lid at the right level, before I try to fix the locks in place.

Before I started cutting any more off the rain channel edge I did a quick test.

I ran a pen along the bottom edge of the rubber seal and then removed it.

This showed that the seal was sitting higher in some areas than others.

It seems that when I added some filler to the fibreglass to "smooth" it out a bit, I left the edges too thick in places.

After a few stop/start sanding sessions I had "narrowed" the rain channel edge all the way around.

Then I put the rubber seal back on and there has been only a marginal improvement to the gap along the top edge.

But the bottom edge is almost perfect, which makes sense as I started working on this end & spent more time on it.

Well, apart from the bottom corner on the driver's side which is "curling" up a bit.

This is due to the fact the fibreglass is much thinner in this corner than the other side.

So I need to add fixing this to the list of things I need to sort out before tacking the locks.

Although hopefully one more session on the rain channel will at least set the boot lid at the right level.

The only other thing I managed to do today was think about how I would set the level at the top of the lid.

As I need the washers & locking pins to sit "level" in order for me to line everything else up.

So I quickly taped some washers to my bolt spacer like so.

The extra washer on the right hand bolt will allow me to get both sides parallel to each other.

Although I might super glue the washers to the bolts when I am doing the filler work.

Right. I've got to go, cheers, Paul.

PS

I was flicking through Swifty's build in order to find the boot lid "gap" photo I posted above.

This reminded me of the huge number of bespoke parts he has machined/made for his car.

E.g. He has rear lights similar to my Land Rover ones, but his trim rings will make them really stand out.

I can't wait to see the finished car, which will set a new quality bench mark.

|

20th March 2015, 18:26

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Slowly Inching Forward:

Whilst my daughter is much better, she spent another day off school today, so just a bit of car work for me.

Although I thought I'd start with the Wembley view of the partial Solar Eclipse.

I managed to carry on sanding down the rain channel edge so the boot lid rubber seal can sit lower.

I think this is as good as I am going to get the top edge.

As there is a little bit of distortion around both sides of the driver's hump.

( No doubt due to cutting the lid out in the first place. )

So this is something I will come back and sort out with some filler when the lid is fixed into position.

In order to get a best fit of the lid, I needed to make one adjustment along this panel gap.

You can also see that I've rubbed down some of the filler previously used to build up the around the top holes.

Actually I spent a bit of time making very small adjustments to other gaps around the lid.

Whilst any photo seems to distort the angles / gaps, this is the best view I can get of how the lid sits now.

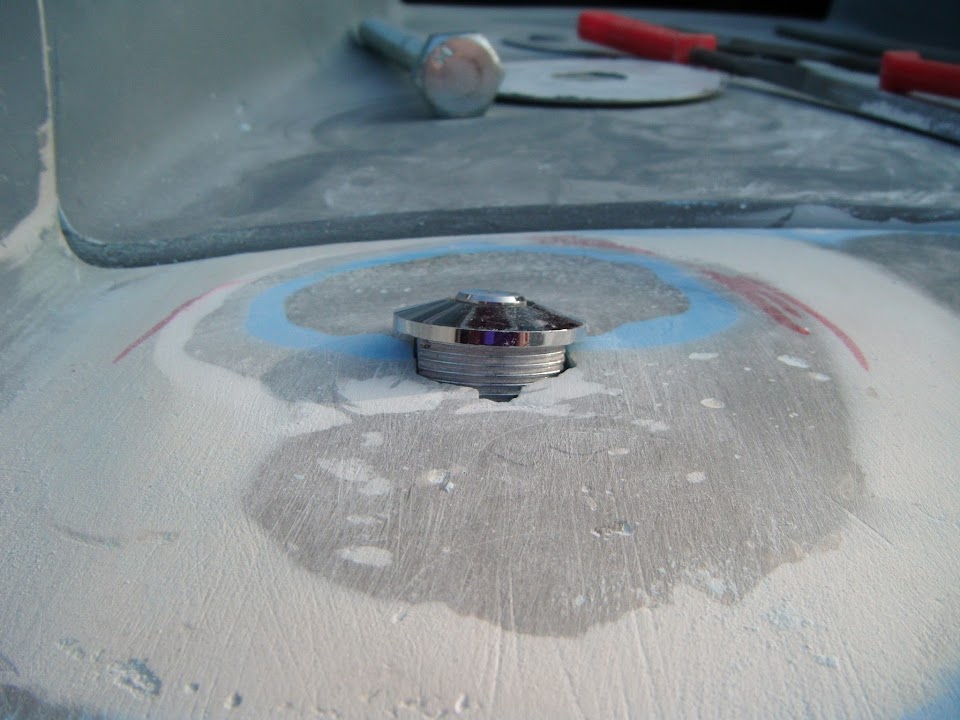

I also managed to add some fibreglass filler around the top two holes.

Although my master plan of using my bolt separator to help me get a nice level failed miserably.

Thankfully I also got the chance to sand that down.

Then I decided to pop the locks in and have a bit of a play, despite the fact I still need to tidy this area up a bit more.

I could get the fixing bolts to hang freely below the locking pins.

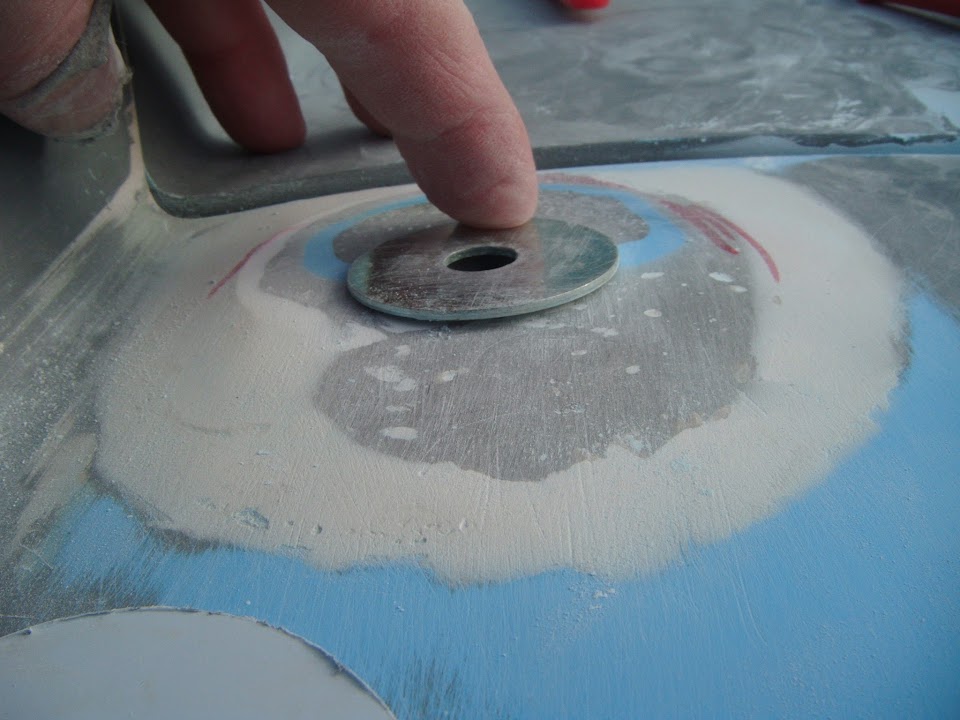

So I used a couple of washers to mark the position underneath.

Which could then be viewed from above like so.

The spreader washers I made the other day just needed a minor trim to match these new holes.

Unfortunately my attempts to level these on a bed of fibreglass filler also failed.

So I will have to put a thin layer of filler over the top if I want these two surfaces to be level.

But I want to fix the locking pins to the boot lid before I go any further.

However, I need the new washers to arrive so I can double check the level of the top surface of the lid.

Then I can make sure the underside of the lid is parallel to that too.

I know this is a lot of work for something that should not be this difficult.

But I think I am slowly getting to the point where the top two locks will eventually work. < Touch Wood >

So until next time, take care, Paul.

|

20th March 2015, 22:16

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Paul, the way your boot lid is at present, its begging for two hinges at the rear and the T shaped handle in place of the ring.

That would be an easy fix, and an end to your problems?

|

21st March 2015, 08:29

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Quote:

Originally Posted by Scottie22

Paul, the way your boot lid is at present, its begging for two hinges at the rear and the T shaped handle in place of the ring.

That would be an easy fix, and an end to your problems?

|

Or an even simpler solution: don't bother with the hinges, add a couple of dowels at the forward edge to mate with matching holes, put the T handle lock at the back and just unlock, lift and pull the panel out to access the boot.

Dare I say it but with all the fasteners, handles and loops, at the moment it's perhaps in danger of looking a bit fussy.  |

21st March 2015, 13:32

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie & Mister Towed - Thanks for the replies chaps, as this boot lid is seriously getting me down.

Although with a bit of luck, I may just have stumbled upon a KISS solution...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Last Chance Saloon:

In one last desperate roll of the dice I have gone back to the other type of lock I have, which thankfully slots into the same size hole.

After the filler work I did around the holes the other day, this is the 180 degree sweep of the "open" & "locked" positions.

So if I made a simple metal bracket like this.

I could bolt it to the mounting plate like so.

( Excuse the blurry photo. )

I could also add a small side brace to help fix the two horizontal sides.

The locks come with a washer with four spikes, which I assume are for fitting on the inside of the body work.

Although I'd be tempted to drill four small holes to the depth of the spikes and fit them on the "sunny side".

I could still add a washer on the inside surface so it is supported on both sides.

Before I waste any more time on this, is this solution likely to work?

Thankfully I have other family stuff to do now, as it is bloody cold outside.

Take care, Paul.

|

21st March 2015, 16:38

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Thank **** For That!

I did get another chance to play outside, so when I found an off cut almost the right size it was a race against time.

A quick trim and a bit of hammering later and I had this.

Note:

I put a slight bend on the leading edge to guide the latch home.

But before I could test this, I needed to sort out the lid first.

Thankfully my M18 washers arrived after my last post and saved me from myself...

"I'd be tempted to drill four small holes to the depth of the spikes"

Really?

When using the washers I bought for this purpose would clearly be a better idea.

So that was the sunny side taken care of, now I needed to sort out the underside.

A quick sand down later...

And I had a much better fit.

Note:

I will add some fibreglass matting around the sanded down hole, to increase the depth, but still keep it level.

Then I drilled a hole in the bracket and bolted it into position.

Then I put the lid on and tried the lock, it just needed a bit of downward pressure to squash the rubber seal, but it bloody worked!

So here is the boot lid with one working lock.

You have no idea how happy this makes me, as this has been a complete nightmare from start to finish.

I will add an extra bolt to the bracket to prevent twisting, but I will use the same approach for the other top lock.

Although the bracket will be a bit smaller to take account of the curve in the lid.

I know I still have to form a master plan for the two bottom locks, but one step at a time.

Cheers, Paul.

|

21st March 2015, 17:17

|

|

Senior Member

|

|

Join Date: Jan 2015

Posts: 168

|

|

Looks o.k. to me.

I would weld a piece of flat at the far end(on the picture)of the bracket to secure it from bending up when in use,otherwise you can get a lot of play in the lock as the bracket is only a piece of bend flat.Just connect the up and downside together will prevent disforming

René

|

22nd March 2015, 10:23

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Rene - Cheers, I will definitely weld in an extra piece of metal to brace the "catch".

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Sunday Morning...

... is not the best time to be working on the car, as making noise is not very neighbourly.

Unfortunately, the first "catch" bracket I made yesterday required an angle grinder, a lump hammer & an electric drill.

So I started with some cardboard and scissors to make the template for catch #2.

( Which is not the same size as #1 due to the curves in the lid. )

I also marked up where the rubber seal ended near the first catch, as I want to build that up with fibreglass.

( Sorry it is not easy to get decent photos from inside the body shell. )

I ordered another pair of this type of lock last night, as this approach looks simple enough for me to make work.

Although I will need to relocate the fixing holes along the bottom edge of the boot lid.

As in their current position, there is no enough room to turn the "cam lock" through 180 degrees.

By chance, it looks like I will be able to get away with fitting them in line with the "pointy end" of the aero humps.

Unfortunately, the "catch" design will not be quite as simple as those along the top edge.

But at least I still think I can make it work, which is a big step forward from where I was a few days ago.

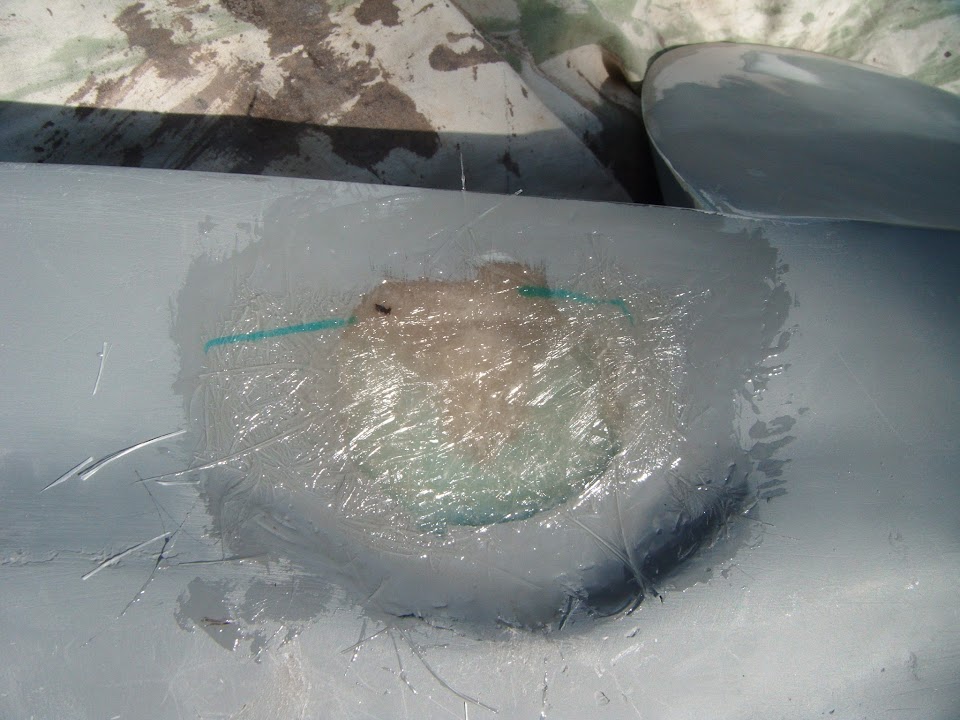

I then took the lid to the back garden where I did some fibreglass work.

I taped up one side of the two holes on the bottom edge of the lid & roughed up the corner that is currently "lifting" a little.

I mixed up a small amount of "home brew" fibreglass filler for the lock holes.

Then added some matting to the corner, over the top of the "filled in" hole.

I also added some matting to the area below the first lock hole that I fitted yesterday.

( I will re-open the hole for the lock when this has set. )

Don't let the rays of sunshine in these last photos fool you, I was wearing a jacket and woolly hat doing this work.

Although at some point I am going to have to cut the grass, but that means sorting out the shed to reach the mower!

As you can see, there are a few car building related products in the way.

At this point I have got to down tools and get one with some domestic chores.

With a bit of luck I will get a chance to make the second catch later on this afternoon.

So until then, take care, Paul.

|

22nd March 2015, 16:33

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Sunday Afternoon - Part 1:

I was only expecting to get a brief car session this afternoon, as I was due to take my daughters to the cinema.

However, they now want to go another day, so I was able to "crack on" with the build.

First job was to tidy up the fibreglass work I did in the morning.

Note:

I will also add some filler from the "sunny side" to leave just enough space for the lock.

( Whereas the locking pins needed extra "slots" cut into the top & bottom of the hole. )

Then I made the second "catch".

Which bolted into place like so.

And looks like this "in action" when viewed from below.

Which means, subject to a bit of fine tuning & bracing, the two top edge locks are now done.

After so much messing about with the locking pin option, this is a huge relief.

I can't start work on the bottom edge locks yet, as they are not an exact match for the top ones.

So rather than guess where everything will go, I'll simply wait until they arrive.

Instead I turned my attention to issue of fitting some locating pins.

( The "cam locks" will only stop the lid from coming out, they will not fix it into position. )

I spent a bit of time beard scratching trying to work out ways of doing this.

Initially I was planning to re-use the plates at the bottom corners.

But they will be used to fix the catches for the bottom locks.

So rather than add anything to the existing brackets, I decided to add something new to the sides, around here.

The next step was to work out what I was going to use on both the body shell and the boot lid.

So after a rummage through the piles of stuff in the shed, I dragged out these two off cuts.

One piece was used to make two mounting plates for the locating pins.

Note:

These are currently too long, but I will only trim them to side when the boot lid is side is sorted out.

But it was the 90 degree bend in the other piece that had really caught my eye.

As this gave me the idea for what to fit to the boot lid.

The plan is that the locating pin will slot into this & be adjusted so it will not reach the lid itself.

I am sure there are easier ways to do this, but at this stage, if it works, then that will do for me.

End of Part 1...

|

22nd March 2015, 16:35

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Sunday Afternoon - Part 2:

The "V" section will be attached to the boot lid around here.

And when the mounting plate is 'glassed to the rain channel, the locating pin will look something like this.

( As I said before, I will trim the plate once everything else is lined up. )

There was just time to start fibre glassing these brackets to the lid, so I headed back to the garden.

Well I did when I remembered that I now needed to unlock the boot lid first.

Eventually I will also build up the area around the hole to give a "cone" shape to guide the pin into place.

But for now the lid looks like this.

Note:

I had a slight "mishap" with the bracket on the left of the photo, but it should set nicely even if it doesn't look pretty.

With a bit of luck, these brackets will also help to protect the locks when the lid is left on the ground.

Given how fed up I was with this lid on Friday evening, this has been a great weekend's work.

I'll certainly be glad when I no longer have to crawl underneath the body shell to check things.

So until next time, take care, Paul.

|

22nd March 2015, 17:18

|

|

Senior Member

Enthusiast

|

|

Join Date: Dec 2006

Posts: 1,130

|

|

Paul, it's great when a plan comes together :

Well done, it's looking good  |

23rd March 2015, 16:49

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Micky1Mo - Thanks.

I just wish I could come up with a simple plan when I start a job, rather than go round in circles first.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Boot Lid Locating Pins - Take 2:

I've reached another "Ying & Yang" point, where good progress on the car has left me behind on other stuff.

So despite feeling very positive about the boot lid after the weekend, I only spent a bit of time on it today.

Also, whilst the following work may look like a step backwards, I actually see it as a positive move forwards.

You see I spent some time yesterday looking back at the photos of the "V" brackets I'd 'glassed to the lid.

I was trying to think of the easiest way to "guide" the locating pin home when the lid is in use.

My initial thoughts involved "building up" the area on top of the hole with some sort of internal "cone" shape.

But this was getting complicated/messy and rapidly moving away from KISS principles.

So I've decided the best thing to do would be to "fill in" the "V", so that it was effectively a solid, not a void.

The only problem was that this was going to be a pain to do with the brackets already in place.

So the "simple" solution was to cut them off and start again!

But first I trimmed the "open" sides to an angle like this.

Which should make it easier to attach this bracket to the lid on all four sides.

Then I carefully cut the brackets off & tidied up the lid surface.

Note:

I also marked the centre point of the hole "externally", so I could line things up when 'glassing the brackets into position.

( This is where I went wrong yesterday when I lost sight of my guide "mark".  )

The extra matting I put "over the top" yesterday, allowed me to remove the gel coat from the inside today.

And this is what the insides of the brackets look like after seven layers of matting have been added.

That was as thick as I was prepared to go in one session & I was very careful to ensure each layer was soaked in properly.

Anyway, I left that to dry & got on with other things...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

The good news was that the first layers of matting had set "tightly".

The bad news was this meant there was still room for another seven layers.

Note:

To do this work takes no more than 50ml of resin, which is less than half of this pot.

Yet all the time consuming setting up before, and cleaning up afterwards, remains the same.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

My last quick session of the day saw all the rough edges tidied up.

Then I fibre glassed the brackets back onto the boot lid, although this time I could use all four sides.

Note:

I have completely "filled in" the original locating hole.

The plan being that I will now drill the locating hole and the "guidance cone" in situ.

That way it should be easier to ensure that everything lines up correctly.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

So whilst I appear to have ended the day in pretty much the same position as I ended yesterday...

I am still happy that this will give me a better result in the long run.

Until next time, take care, Paul.

|

24th March 2015, 14:11

|

|

Senior Member

|

|

Join Date: Jan 2012

Location: france

Posts: 308

|

|

thank you rattler

|

24th March 2015, 15:40

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Rattler - No worries, I've just added a few more photos to both threads.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Fine Tuning - Part 1:

I was hoping that the fibreglass "mounds" I fixed to the boot lid yesterday could also act as "feet" for the lid to rest on when removed.

Unfortunately, a quick test this morning showed that the curve of the lid is just too great.

I had loosened the eye bolt, in case I needed to cut it to a particular height to act as another "foot".

But now it was clear I will just need to pack a dust sheet in the boot to protect the lid, so I quickly trimmed the eye bolt down to size.

Before I did any more work on the lid, I thought I'd better double check that it still fitted into the opening.

So there is plenty of room to mount the locating pins somewhere around here.

In terms of timing, I am still waiting for the bottom edge locks to arrive.

But I want to have all four locks in place and working, then set the panel gaps, then fix the locating pins.

Well at least that is today's plan.

Next I did some filing to fine tuned the position on the lock in the left of this photo.

From this:

To this:

It only needed to move a few mm, but now the two locks are the same distance from the edge.

( Even if it doesn't look like that in the photo. )

Next I fixed how that lock sat in the lid.

From this.

Via a bit of sanding / levelling out.

To this.

Then I roughly sanded down the underside of the lid.

Note:

I know this side is not on view, but I want to practise my painting on this side before I start on the car itself.

That way I will have a better idea of how much preparation is required to set a smooth finish.

Then I felt a slight drop of rain & looked up to see this.

But by the time I'd quickly brought all my stuff into the porch, the rain had stopped.

So I decided to take a chance and do some filler work.

First up was some fibreglass filler that I used to "tighten up" the top edge lock holes, after putting some tape underneath.

I then gave a quick skim to a few sections of the rain channel edge.

As there were a few rough spots following the sanding down work I did the other day to re-fit the rubber seal.

End of Part 1....

|

24th March 2015, 15:41

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Fine Tuning - Part 2:

There was just enough filler left to add a bit around the rear light holes on the passenger side.

Then I mixed up some normal body filler to do the underside of the boot lid.

Unfortunately, before I could finish putting the filler on, the rain returned.

So I quickly covered the body shell (for the rain channel) & then carried the lid into the porch.

Now this caused two problems:

- The first is that in my haste to get out of the rain I forgot to finish off the smoothing of the filler.

- The filler absolutely stank the house out.

Now given that my wife's niece is coming around for dinner later, this meant I had to "air" the house once I could move the lid outside.

Still I had the house fully sorted out and the dinner table laid before I headed out to start sanding.

It was bloody hard work, but I have now finished the underside of the lid.

But no sooner had I taken the last photo when the rain returned.

I packed everything away and was just debating whether I'd get a chance to get some etch primer on later, when the hail & sleet arrived!

So I took that as a sign to call it a day.

Until next time, take care, Paul.

|

25th March 2015, 04:01

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

While there is no knocking the cracking results you are achieving, I do think that your version of keep-it-' simple' may need reviewing at some point

Keep up the good work matey  |

|

Currently Active Users Viewing This Thread: 3 (0 members and 3 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 13:28.

|