|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

26th July 2014, 19:47

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

A Long Day - Part 4:

Matching Spitfire Arches to Body Shell:

My plan is to join the Spitfire arch to the side of the body shell.

But it occurred to me that these arches could give me a reference point for the body shell arch openings.

So I jacked the car up, put it on axle stands and removed the wheels.

Made a "low tech" guide rail for my marker pen.

And after going over the black line with a thicker red marker, this was the result.

Driver's side:

Passenger side:

I will come back at look at this a bit more closely another day.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Other Odd Jobs:

I sanded down the filler on the inside of the scuttle.

And the filler on the inside of the body shell repair.

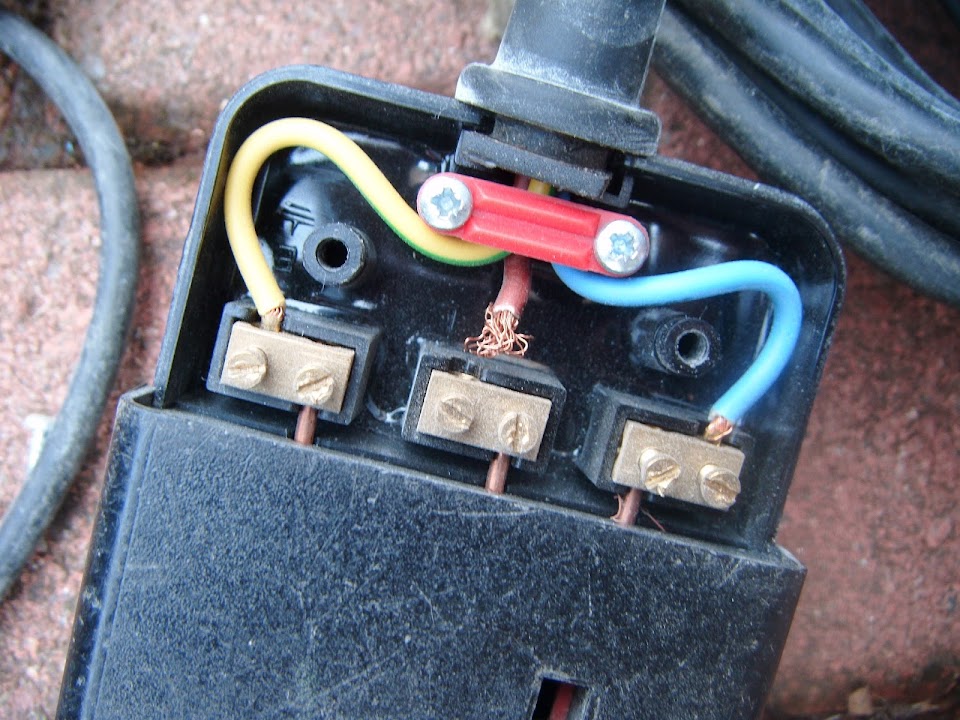

That was after I had re-wired my extension lead, as a wire had come loose.

I have marked up a straight line across the back of the cockpit.

Which means I will have something to aim for when I try to build a new edge here.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Right, I need to have a rest now, so I will catch up later, Paul.

PS

I must end with some praise for my wife who helped me move the body shell multiple times today.

|

26th July 2014, 21:05

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Good work Paul, good work.

|

27th July 2014, 17:38

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - Cheers.

I know there is still a long way to go, but it does feel good to keeping ticking the jobs off.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

A Short Day:

Too many other things to do today to repeat yesterday's long car session.

But I did make a bit of progress, so at least I am still heading in the right direction.

I decided to give the bottom edge a bit of a trim / tidy up.

Although there is no point in drawing a straight line, if I then cut a slightly wonky one.

With the back edges of the tail pipe exits trimmed, I used a cutting disc to roughly get the shape at the front.

Before using a grinding wheel to finalise the shape and get rid of any flaky fibreglass.

Then I stuffed fibreglass filler into all the small voids around the edges.

While that was setting I added more matting to the inside of both the tail pipe exits.

Later on, the filler was given a rough sanding down.

I am currently debating whether to build up the edge of the cut out, or keep it flush.

With the body shell back in position, you can get a good idea of how this will finally look.

I must confess that I am very happy with how this has worked out, not perfect by any means, but good enough.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I also added a second layer of matting on the driver's side.

A quick check of the rear cockpit framework showed that it was not strictly square.

So I will stick to the line I drew on the body shell rather than take any measurements from the frame.

As I've said before, I need to pick my battles if I am ever going to finish this build.

Until next time, take care, Paul.

PS

Not sure if it is the good weather, but the number of people stopping for a chat while I work these days is unbelievable.

The most common question remains "Is it a AC Cobra / D Type Jag ?"

Whilst two different groups of "yoof" have confirmed that my car is " sick".

Which I believe is as complimentary as it gets these days.

But my favourite conversation to date remains an elderly couple passing by...

Husband to me - Is that an MG?

Wife to husband - Don't be silly, can't you see it's a E type.

|

27th July 2014, 18:38

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

Looking good, Paul. I like the exhaust contouring - very neat.

|

28th July 2014, 16:10

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Oxford - Thanks, I am still amazed that they have worked out as well as they did.

Fibreglass work is still pretty new to me, so I am picking up ideas & tips from you, Mac, Mr T, etc.

Can I ask where you got the foam strip you used before cutting the back end of your body shell off?

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Bonnet Pin Support Brackets:

The weather has got in the way of me doing anything constructive outside today.

However, I did managed to sneak a quick trip to my local Wickes to have a look at some bracket options.

At this point, all I know is that I need to support the pins anywhere from 3" to 6" away from the Spitfire bulkhead.

Unfortunately, the brackets I could find that that reached out 6", also went down 6", making them rather large overall.

Still, this wouldn't be the first over-engineered solution to find its way into my build.

I will test fit them as they are, but they will probably be trimmed down before they are finally fitted.

Either way, using something ready made will certainly save me the time & touble of making something from scratch.

Until next time, take care, Paul.

|

29th July 2014, 20:24

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

A Slow Grind - Part 1:

I decided to sort out the rear cockpit "line" before I move the body shell into my back garden.

But first I need to decided how the rear panel was going to fit.

So I cut out a shape in plywood that would fit in front of the rear frame.

I know this is the traditional approach taken by Spyder builders.

But there is no little room for my seats, that this will not really work for me.

A quick trim later and the panel was able to sit inside the rear frame work.

I will need to make some holes for access to the fuel gauge wiring and the seat belt anchor points.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

The other part of the rear cockpit I wanted to look at was an extra support panel in the middle, between the two humps.

Not a great photo, but this is the area I have to play in.

So I lifted the body shell a bit, to get access to frame work underneath.

An off cut of plywood from making the cockpit panel seems to be about the right size.

But the more I looked at it, I realised I would need to add extra frame rails to support the plywood.

In which case, I might as well just weld a metal panel on top of these extra frame rails.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

I did some careful checking on the way the scuttle was fitting over the Spitfire bulkhead.

At which point the edge of the cockpit on the passenger side shifted slightly behind the frame work.

So I could actually shift the edge back a little bit further than my initial mark.

I still have a problem with the way the face of the driver's hump sits.

Part of this problem is due to a "dip" in the face itself.

( It actually gets worse the lower down the face you go. )

By now, I knew I would just have to do some more "cutting & shutting".

So the body shell came off and the angle grinder & jig saw came out.

I cut away the rear lip, both cockpit corners and trimmed the sides of the cockpit while I was at it.

Note:

After doing a bit of playing around with plywood, I think the cockpit sides need to follow the angle of the frame.

Otherwise, the internal walls will appear to be going in a different direction to the external ones.

I will come back and fine tune the corners and sides after I have sorted out the centre of the cockpit first.

End of Part 1...

|

29th July 2014, 20:25

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

A Slow Grind - Part 2:

This is the effect of my handiwork with the body shell in position

Before:

After:

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Then it was time to start rebuilding the lip I had just removed.

I dug out the cardboard that was initially going to form my aero screen wind deflector.

Then I chopped it into sections, added some parcel tape and clamped it into position.

I added an extra bit of tape to the top edges of the "gapping wound" in the rear body shell.

So after turning the body shell over, this was the first area I could work on.

Multiple layers of matting later and the new cockpit lip was starting to form.

By now it was getting rather late, so I decided to leave the body shell on the drive with the clamps still in place.

( You will notice I had to do my cleaning of the drive around it. )

I just threw a tarpaulin over the top to tidy the whole thing up a bit.

This was one of those days when I had to take some steps backwards to move forwards.

But at least I am still moving forwards.

Until next time, take care, Paul.

|

29th July 2014, 20:57

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Nice work Paul.

At the stage you are at now, have you thought about access to the rear transverse spring?

When I put my rear seat backs in my car, I used self tappers rather than rivets, in case I ever busted the spring, or needed to remove it for any reason.

Just a thought..........

I'd hate you to weld it all in then, think Oh sh*t!

|

30th July 2014, 07:03

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

You could always cut the back off.........

|

30th July 2014, 07:30

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Quote:

Originally Posted by oxford1360

You could always cut the back off.........

|

That's not a bad idea and will be duly stolen if I ever build another.

I have been wondering how the builders who're fitting Spitfire rear floor/inner arches are going to access the rear spring/diff bolts.

Both Phil J and I have had the odd issue with the diff bolts coming loose (especially when we had lowering blocks fitted). With no inner arches access is 'not bad' but it's not what you'd call easy. A flip rear would give you much better access and would look really cool too. |

30th July 2014, 09:05

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie, Oxford & Mr T - Cheers chaps.

There is a " cunning plan" to provide access to those bolts that isn't 100% finalised yet.

If I quickly bring up this photo from the other day...

Access to the fuel gauge and the fuel line itself will be via a removable panel in the rear cockpit wall.

Access to the bolts and the fuel tank filler hose will be from the rear.

I was actually looking at this yesterday, although I didn't want to mention a half baked plan just yet.

But as you've asked....

I have looked at various boot openings in numerous build threads and think an access panel will be best for me.

( As I will not need to use the boot for most short trips in the car. )

Some sort of cross between Tribute's Kobra...

And something like this, that cuts across the twin humps...

Although I am still not sure where I am going to make the various cuts required.

In fact, there is so much work involved I've been trying not to think about it too much at this stage.

But I do need to do something, so I'll just add it to the "To Do" list.

Right, I'm off to check how my new cockpit lip is getting on.

Cheers, Paul.

|

30th July 2014, 19:59

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Struggling - Part 1:

Today's top tip is build up a cockpit edge the way Mac did, like this.

Whatever you do, don't copy my little bit at a time approach.

It started off well enough as the work I did yesterday was revealed.

Even the join along the top edge worked well.

So I added some fibreglass filler to the top edge of the "gapping wound" like so.

The new lips even cleared the frame when the body shell was put back on.

Even without the corners being 100% finalised, there is already much better clearance for the seats on both sides.

Then I started on the next round of lip building and had my first issue with the hump.

As you look at the photo, the body shell on the right of the hump is significantly higher than the body shell on the left of the hump.

So without anything with an edge and a curve to play with I was going to have to do this in stages.

I also roughly sanded down the filler so I could work in this area too.

I forgot to mention yesterday, that unlike Scottie I only have 4 clamps to play with, which is not helping either.

So this was the set up for Round 2.

Note:

I needed to 'glass behind the hump in order to support the lip I was building along the bottom.

And this was the view just before the work began.

Two sessions and multiple layers of matting later and it looked like this.

I also added a second layer of matting to another part of the driver's side of the body shell.

Between the twin tail pipe recesses.

And behind the corner crack I repaired the other day.

With the formers removed and a light tidy with the grinder it looked like this.

End of Part 1.

|

30th July 2014, 20:00

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Struggling - Part 2:

Then I set things up for Round 3.

Another two fibre glassing sessions and multiple layers of matting gave me this.

After formers removed & a quick tidy.

Everything was actually looking good until I re-fitted the body shell...

Obviously, there was still a bit of work to do, but the foundations of the rear cockpit lip appeared to be in place.

But all was not well, as I needed to weigh the scuttle down to stop it wobbling all over the place.

Unfortunately, when I was adding extra fibreglass to re-enforce the new lip, I was also building a clearance problem.

So I marked up the offending areas on either side of the hump.

In order to save time testing, I did the grinding with the body shell propped up.

Although I needed some "steps" so that I could actually climb over the body.

After:

The net result of this work was to simply move the problem to a different area.

However, I added some cardboard under the centre of the rear cockpit frame work.

This seems to have done the trick, so I will definitely be building the support panel in this area.

However, I might need to re-draw the lines for the Spitfire wheel arches now I know where the body will sit.

So another one of those days where new jobs are added to my list, quicker than I can tick off the ones already there.

Until next time, take care, Paul.

|

30th July 2014, 21:59

|

|

Senior Member

|

|

Join Date: Apr 2012

Posts: 1,163

|

|

Paul, there is no wrong way or right way, just your way, sure you may do it differently next time but it will still be your way :-)

Keep at it

Mac

|

1st August 2014, 19:40

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Mac - Cheers.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Making Brunel Proud...

Lots of family stuff going on at the moment, but I did get a chance to do some car work this afternoon.

Here is the area where I want to build my support structure.

Note:

The mess is one of the reasons I want to get quite a bit more of the body work done at this stage.

All of the dusty stuff still needs to be removed so I can do the final round of work on the underside.

But it would be a pain trying to keep the "Moon Rover" clean if I had to keep attacking the body shell.

Anyway, I cut a length of box section and clamped it into place.

It made a nice change to be welding, rather than doing messy fibreglass work.

In true "Belt & Braces" style I wanted to add a couple of cross sections.

They just needed a slight trim due to the angles of the framework.

With those welded it, this is what it looked like.

So the next step was to cut out, clean up & clamp a section of fresh metal over the top.

Again you can see the impact of the angle of the framework here.

So I simply welded one side first, before clamping the other side down and doing some more welding.

This is as far as I managed to get today.

So I will have to come back and finish the welding another day.

Although, to be honest, it is already rock solid now and it can take some serious weight without flexing.

Based on Mister Towed's feedback, this is an area where your hand instinctively reaches to lift yourself in & out.

So I'd rather over-engineer a solution, than under support the area.

I even made sure there was enough room for me to rotate the fuel pipe through 180 degrees.

This is on the "To Do" list, I even have a new olive in a box ( somewhere  ) ready for the job.

Thankfully the body shell still fits over this and the scuttle wobble had gone too.

So a big blob of bonding paste, when the time comes, should support the rear bodywork very well.

The rear of the body shell will also get supported in the following places:

- By joining the sides of the body shell to the Spitfire rear wheel arches.

- By joining what is left of the Spitfire boot floor to the back of the body shell.

- I might also add some extra support when I put the boot opening in place.

As I've starting playing around with the cockpit panelling, it is slowly becoming much clearer to me how the body shell becomes "fixed".

Until next time, take care, Paul.

|

8th August 2014, 13:13

|

|

Senior Member

|

|

Join Date: May 2013

Posts: 2,161

|

|

Hi Paul, when you put your boot opening in, if you put in a rain channel, that strengthens things a lot, it did for mine anyway!

Gives the whole boot area rigidity

Good luck with it.

|

9th August 2014, 18:56

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

Scottie - I do plan to build a rain channel for the boot lid / access panel.

I will also be adding some extra cross bracing in that area and to the lid itself.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Family Holiday:

Just back from a week away with the family, which explains the lack of progress on the car.

Although I did use some of the time away to work on various car related "To Do" lists.

Obviously, as soon as you write things down, you realise there is still a very long way to go.

But I do find that these lists are a big help to me when it comes to figuring out the order I need to tackle the work.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

DVLA:

Just before we left, I received a reply from the DVLA, following my latest attempt to check the re-body rules.

The bad news is that they didn't answer my bumper bracket questions at all, just sent me forms and a booklet.

But the good news is that I now have a contact name, so I have also drafted a reply letter while I was away.

However, the really good news is that the V5C changes to go from a Spitfire to a Cordite seem less than for a Herald to a Spyder.

Based on other builders' experience, these days the "Make" must remain as "Triumph".

I have no problem with that and as I've said before I will probably copy AndyP57's use of the new Triumph Motorcycles logo.

So the only V5C change I need to make is to the "Model", which must change from "Spitfire 1500" to a new name.

I have picked a new name ( not Cordite), but want to wait until the paperwork is sorted out before revealing it.

The "Body Type" is already listed as "Sports", so apart from colour, there are no other changes required to my current V5C.

So I will keep you posted if the DVLA provide the clarification I am now seeking in my reply letter.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Looks like tomorrow will be a wash out, so it may be next week before I get back working on the car.

Take care, Paul.

|

9th August 2014, 20:03

|

|

Senior Member

|

|

Join Date: Dec 2013

Posts: 839

|

|

Hi Paul did DVLA mention anything about a visual inspection in the reply or is it a case of sending the forms off and waiting to see what their response is, i did read some were that you have to provide invoices and build diary to back up a re-body case, is this mentioned in the DVLA info.

Which forms and booklet did they send as i will have a look to see if an online copy is available.

|

10th August 2014, 11:19

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,056

|

|

DVLA Info:

It seems my last post has generated a bit of interest, so I have just done some digging on the 'net.

This is the stuff I was sent:

DVLA Booklet INF26

http://www.direct.gov.uk/prod_consum.../dg_180218.pdf

Form V627/1

https://www.gov.uk/government/upload...7X1_270913.pdf

V894 Reply Slip

Apparently this is not available on line.

What is not clear to me, is if the "re-body" rules used by previous Sammio builders are still around.

Based on INF26, I think Section 2 (Vehicles that have been rebuilt using a mix of new and/or used parts) applies.

Because Section 5 (Kit conversions) refers to " a kit of new parts" and IVA.

So I am about to check that my build falls under Section 2, as that seems closest to the old "re-body" rules.

In my case, the chassis VIN matches the V5C, so counts as original.

Plus I am re-using the suspension, axles, transmission, steering & engine from my donor.

However, the risks are that the "Kit Conversions" section also mentions " the general appearance of the vehicle will change".

Hopefully this means a significant change in appearance.

E.g. A 4 door, 5 seater Ford Sierra saloon into a 2 door, 2 seater Pilgrim Cobra replica.

As previously mentioned, my Spitfire "Body Type" is listed as "Sports" and I would argue that the general appearance will still be "Sports".

The DVLA did want photos of "before" and "after", including one with the registration number on it.

Plus information on the changes that were carried out, but supporting invoices.

For me, the main invoices required would be:

- Original donor car

- Sammio Cordite kit

- Second hand body shell from Ebay used for my bulkhead & rear arches

Another area I want to check is the application timing as the DVLA talks about the completion of the build.

Whereas, I want to apply for the V5C changes as soon as the body shell is bonded into place, complete with internal panelling.

My argument will be that I need the revised V5C in order to MOT, Tax & insure the car for the road when it is complete.

So I'd rather get the paperwork sorted out in advance, rather than start the process when everything else is done.

Obviously this whole area is a can of worms, so I will see what their next reply says.

Cheers, Paul.

|

10th August 2014, 16:30

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

Paul,

I did some reading up on all of this malarky the the other week and we're more than covered by one of the new schemes, i just can't remember which off the top of my head.

I made some notes in work, so i'll dig them up in the week as i'm nearly at the stage where i'm about to sort my V5 out anyway.

|

|

Currently Active Users Viewing This Thread: 2 (0 members and 2 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 13:40.

|