|

|

| Sammio Builds and discussions Sammio bodied car builds and specials |

11th December 2012, 09:25

|

|

Senior Member

|

|

Join Date: Mar 2012

Location: Doncaster

Posts: 116

|

|

well done with the engine mate! With my broken leg I expect you to overtake me so I can start learning from you!

|

11th December 2012, 10:45

|

|

Senior Member

|

|

Join Date: May 2011

Location: Somerset

Posts: 1,671

|

|

If you're doing some welding practice then there is a good supplier on e-bay (might even be metals 4 u?) who do variety bundles of box section and sheet.

I bought a few packs so that i could practice with the different settings on my welder and also so that i had odds-n-sods lying around in the garage in case little jobs cropped up!

|

11th December 2012, 11:24

|

|

Senior Member

|

|

Join Date: Mar 2012

Posts: 1,152

|

|

Quote:

Originally Posted by davecymru

If you're doing some welding practice then there is a good supplier on e-bay (might even be metals 4 u?) who do variety bundles of box section and sheet.

I bought a few packs so that i could practice with the different settings on my welder and also so that i had odds-n-sods lying around in the garage in case little jobs cropped up!

|

I did the same and made some wonderfully bizarre sculptures........

However, a far cheaper way is to track down a local engineering firm that keeps box, tube and sheet. I am fortunate to have a very friendly one just a mile from The Glade and they will sell off-cuts or full lengths/sheets much much cheaper than eBay and without the postage. I have had to get out of the habit of questioning them when they say the price.

I had no contact with them before I started building e.g. I don't have a mate that works there. I just rang them.

Best of luck!

PS The oddments - big and small angle, tube, rod etc. - that I got from eBay are really useful. For example, my special-bush-removal-tool was made with them.

Last edited by oxford1360; 11th December 2012 at 11:27..

|

12th December 2012, 15:15

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Box Section Delivery:

Very happy to say my box section arrived as promised, all wrapped up neatly.

( Note that isn't "real" snow on the cover, but the effects of the freezing fog we had last night! )

Day off passes me by...

Day off passes me by...

Domestic chores, the gas board & my neighbour's flat battery conspired against me today.

So the small little jobs I have lined up between now & Christmas will have to wait until the weekend.

Cheers, Paul.  Replies:

DonnySoutherner

Replies:

DonnySoutherner - I've still got quite a bit to do to catch you up, but I'll try my best.

DaveCyrmu - Thanks, my mate has promised me his metal "left overs" when I see him.

Oxford - Cheers, I'm hoping this & my mate's odds and ends will be more than enough.

Last edited by Paul L; 10th September 2019 at 11:25..

|

15th December 2012, 15:28

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Bonnet Holes:

Cutting the holes out of the bonnet for the headlights was hardly a top priority in my build plan.

But it was a job that didn't involve dragging lots of stuff around which made it ideal at this time.

Having said that, there was still a pile of stuff required...

( Although in fairness, some of this was required for job number two of the day, see below. )

So here is the before:

A headlight outer rim helped me establish a "best fit" position to tape my cardboard template on.

I then marked the two headlight adjustment holes (9 & 12 O'Clock), plus the main shell hole.

I'd left small sections of masking tape under the template so I could drill straight through.

I drilled a couple of holes inside the main shell area to provide access for a hacksaw blade.

However, it was proving difficult to change the direction of the blade to cut a circle.

So whilst I initially thought it would be tricky to use my jigsaw, I had no choice.

In the end I don't know what I was worried about as it was very straight forward.

I just needed to run a rasp file around the hole edges and it was job done.

And here is a headlight I restored earlier...

Note:

There is enough space in the hole to move the headlight up a bit to match the body.

This was just pushed into place to give a rough idea of what it would look like.

Then it was a case of repeating the process on the other side to give this...

I will leave cutting the big hole out for my beer crate grill until it arrives.

Engine Cooling:

This photo Mister Towed posted of his blocked cooling pipe left me wondering a bit.

As I posted on his thread, I'd found some "crud" blocking my heater value when I removed it.

So I reconnected my wiring loom to the car & re-started the engine.

The plan was to leave the engine running & check the cooling pipes were warming up.

But I seemed to be having a lot of trouble trying to balance the choke / throttle levers.

In the end i just couldn't get it to tick over by itself (probably as I was in a rush  ).

What I did notice was that the end of my throttle cable retaining clip is missing.

I'll have to go back & check old photos to see if it was there before & has simply fallen off.

Or I might just order a replacement if it is not likely to re-surface quickly.

The main reason I was in a rush is I could sense the rain was coming.

And sure enough I was forced to abandon all work and cover the car for the day.

This means a temporary dump of everything inside the porch.

( Can you tell my wife has taken the children to visit her sister?  )

I can then put everything away properly without it getting any wetter.

Next Steps:

Sunday will be a "get everything to do with the car" out of the house before Christmas activity.

I will just leave enough bits for one small job next weekend that I can do indoors (touch wood).

So until next time, take care, Paul.

Last edited by Paul L; 10th September 2019 at 11:31..

|

15th December 2012, 16:11

|

|

Senior Member

|

|

Join Date: Jan 2012

Location: Poole, Dorset

Posts: 615

|

|

these are good for cleaning up edges for lights and any other holes you have to cut in fibreglass

Put them in a drill and away you go..

flapwheel.jpg

|

23rd December 2012, 16:35

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Christmas Tidy Up:

The good news is I cleared the house of car parts & tools ready for our final Christmas day preparations.

( Although I did tuck a few things away in a utility room cupboard for one small "indoor" job, see below. )

The bad news is while re-arranging the garden shed I discovered one of my resin containers is leaking.

Thankfully everything is still in the sealed bag it was delivered in, so I'll sort that out after Christmas.

Welding Lessons - Delayed:

Met my mate after work during the week for a quick Christmas drink & to exchange pressies for our children.

Unfortunately, he has a lot on his plate, so my first welding lesson needs to be put back until early January.

Don't get me wrong, I'm not complaining, as he is till doing me a HUGE favour & it will be worth the wait.

I just need to cut one of my 3 metre lengths of box section tube into more "bite size" lengths to practise on.

Missing Throttle Cable Parts:

I went back through my photos and it looks like there was some sort of a clip holding this in place originally.

However, when I cross checked this with the Rimmer Bros. diagram this was the wrong part anyway.

So I now need to order some new bits to bring this all back up to the correct spec. which I hope will stay in place!

Car Alarm:

I posted a question about car alarms here & got some great replies.

So another little bit of shopping required to sort that out too.

Last job planned, but I ran out of time...

I'd planned to make a template for my rear lights, reflectors & number plate before Christmas.

As this was a little job that I hoped to squeeze in which wouldn't make a mess of the house.

But I've spent hours today washing mud off the road, pavement, & driveway following the gas works.

( We didn't want our guests on Christmas day getting mud over their nice clothes. )

That, together with all the traditional Christmas chores means I have to call time on the car for now.

I'm working half day tomorrow, then it is family time until at least the 27th of December.

But as I'd already prepared the following links in advance, here is what I want to do...

It all started out with my computer mock up based on possible dimensions (top row).

This had then became a full scale mock up with everything taped to the body work.

But it was clear I would need a way of evenly spacing everything out, both vertically & horizontally.

So I will lay everything out again on a template & then fine tune this initial rough spacing with a ruler.

I can then mark up all the centre holes for drilling on a single piece of paper / card.

So much for the best laid plans, and all that. But with a bit of luck, that will be my next job.

Until then, I hope you all have a very Merry Christmas & here's to more cars on the road in the New Year.

Ho! Ho! Ho! Paul.  Replies:

TriTone

Replies:

TriTone - Thanks for the tip Tony, I've already learnt a lot from your build thread.

Last edited by Paul L; 10th September 2019 at 11:34..

|

27th December 2012, 18:20

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

I've been a little bit slow getting back into things after Christmas.

So this is more of a "thinking" update, rather than a "doing" one.  Front Indicators:

Front Indicators:

After cutting out the holes for my headlights, I started to think about my front indicators.

I'd bought some side repeaters for the job ages ago as there are no size limits.

This was based on Trevor Bennett's build, one of the first finished cars I saw.

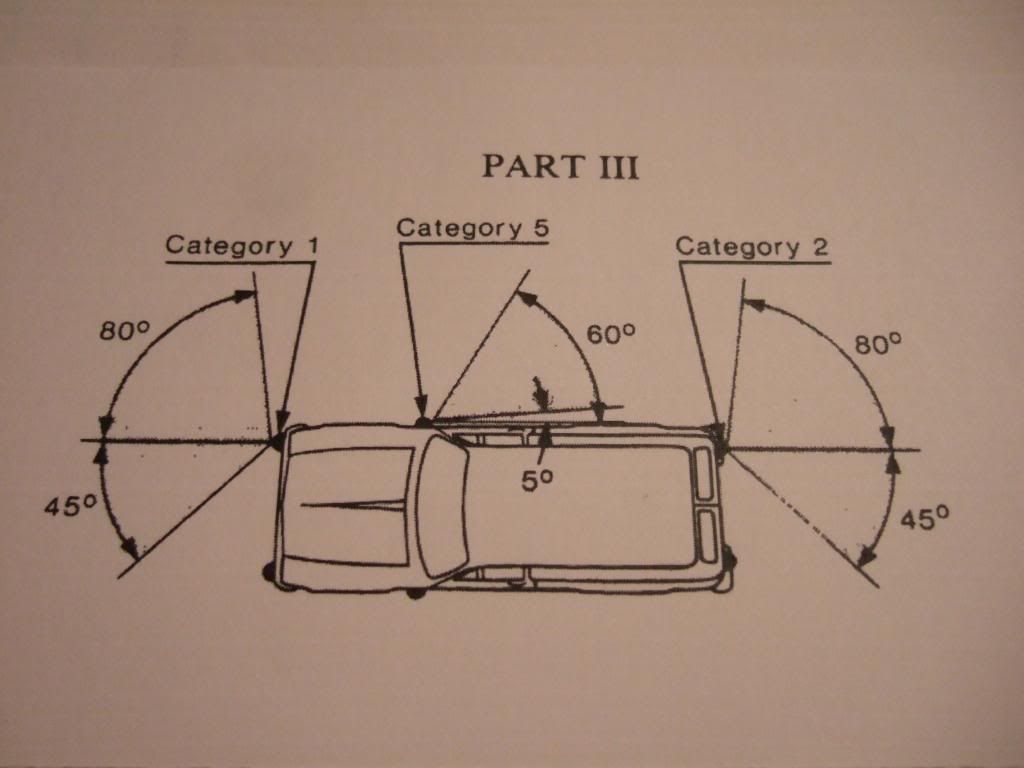

I've since found this diagram which is a guide to the rules about visibility angles.

So I need to extend a 45 degree line back from the front edge of the bonnet's "nose".

This will then give me the furthest inside position on the body work that the indicator can go.

Unfortunately, the original Cordite demonstrator didn't have indicators fitted.

So when it finally stops raining long enough for me to work outside I will mock that up & see.

While I am at it, I will also try my rear indicator for size to see what that looks like too.

Here are a few Spyder examples & I love the fact there is such a variety of indicators used.

So as always, lots to think about.

Hopefully, I might actually get a few small jobs done in the next few days.

Cheers, Paul.

|

28th December 2012, 09:04

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Hi Paul, the viewing angle chart only applies to vehicles registered on or after 1st April 1986.

As even the youngest Spitfires rolled off the production line in 1980 and Vitesse and Herald production ceased almost a decade earlier it's safe to say that no Triumph based Sammio will need to comply with that diagram.

For our purposes Schedule 7 of The Road Vehicles Lighting Regulations 1989 have the following to say about the arrangement of indicators -

(b) A motor vehicle first used before 1st April 1986, a trailer manufactured before 1st October 1985, a pedal cycle, a horse-drawn vehicle and a vehicle drawn or propelled by hand:

Such that at least one (but not necessarily the same) indicator on each side is plainly visible to the rear in the case of a trailer and both to the front and rear in the case of any other vehicle.

Full details about lighting are available here -

http://www.legislation.gov.uk/uksi/1989/1796/made

It's worth trawling through and reading the small print as some of the regulations will affect some donors more than others. As an example, I can have a single rear brake light on my '68 based car, but you'd need a matched pair on the back of a Spitfire, Herald or Vitesse based car if the donor was built on or after 1st January 1971 (Schedule 12, part 1).

Happy reading!

|

28th December 2012, 08:52

|

|

Senior Member

|

|

Join Date: Sep 2012

Posts: 192

|

|

thats one big scoop

|

28th December 2012, 10:18

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Quote:

Originally Posted by CarNoob

thats one big scoop

|

Yes it is, although it doesn't look quite so big from normal viewing angles.

I had to make it that size to clear the thermostat housing in front of the rocker cover with the bonnet sitting where I wanted it. With the unmodified bonnet positioned to clear the top of the engine, the wheels looked completely wrong in the arches.

Before

After

A number of tolerances seem to have worked against me having a low profile bonnet - my engine seems to sit higher than most (wrong engine mounts?) and I fitted my body very low to try to get it to wrap under the off-side chassis rail, which it never quite did, meaning the back edge of the bonnet starts about an inch lower than it could've done.

The good thing about the Sammio design is that it can have various scoops, bulges etc added without ruining the looks (imho). After all, fifties race cars had scoops and bulges in the oddest places, just take a look at all the scoops and vents on this Lancia D24 -

Nice.

|

28th December 2012, 10:31

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Mister Towed - Thanks, that is another great answer.

So all I need to do now is mock up possible locations.

That is if it every stops raining long enough!

Cheers, Paul.

|

1st January 2013, 14:23

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Whilst I thought I might have some free time after Christmas to work on my car, I was mistaken.

My time disappeared due to a combination of family time, my wife's birthday and the rain. *

But mainly I have been feeling pretty rough & under the weather with no energy at all.

* Not my imagination, 2012 now officially the wettest year on record in England.

So just a little bit of tinkering around the edges to report...

Rear Lighting Layout - Take 2:

I'd already taken a measurement between the rear seams when the kit first arrived.

So I knew the biggest area I would have to work with would be around 101 cm.

But I noticed something else when I was double checking this distance the other day.

The body work actually rolls inwards quite a bit at the outer edges like so...

Don't ask me how I missed this before when taping the lights onto the body.

I think I was checking the lenses from above to see that sat squarely on the body itself.

The fact that there were not square to each other seems to have missed me for some reason.

The good news is Mr T's research (see above) shows they don't need to be in a set position.

So I will carry on regardless and the indicators will simply follow the lines of the body "roll".

However, I will bring the lights & reflectors a bit closer together than in the previous mock up.

Thus reducing how far out the indicators will be & so reducing the angle they will sit at.

I also went back to my previous research and re-discovered this Sammio layout.

Clearly if this managed to get an MOT, then I will have no problems with my lights.

I simply used some brown paper to mark up some alternative "bunched up" layouts.

Note: The lights are supplied with a rubber edge that adds a few mm each side.

The thick blue lines represent the seams on the body work.

These photos show the following:

- 30mm between number plate & reflector, then remaining gaps at 20mm

- 20mm gaps throughout

- 20mm between number plate & reflector, then remaining gaps at 15mm

- 15mm gaps throughout

I'll have a think about which of these I think works best & then make a template for drilling holes.

Next Steps:

With a bit of luck I'll feel like going outside at the weekend if I get the chance.

Until then, "Happy New Year!", Paul.

Last edited by Paul L; 11th September 2019 at 08:44..

|

1st January 2013, 16:30

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Yep, the indicators just need to be visible from directly behind to comply with the vehicle lighting reg's for this age of car. I'll be taking a print out of the reg's with me to the MOT testing station come the day, just in case

There's just one more thing though Paul (in a Columbo stylee) - it's probably best not to assume that the rear wing seams are equidistant from the centreline of the car. I wouldn't personally use them as a datum, I would find the true centreline and work my way outwards from there. Then do the final fitting up by eye, and if it looks right, go for it.

Good luck getting the look you want and I hope you have a great start to 2013. |

12th January 2013, 20:29

|

|

Senior Member

|

|

Join Date: Jul 2011

Location: Marmande 47200

Posts: 501

|

|

If you want racing style but with inertia reel check out my thread I found full harnes fixed back to inertia single point.

Cheers pops

|

13th January 2013, 06:28

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Mr T - Outstanding reply.

Your constant support is one of the main reasons I am still chipping away at this project.

You have proved that all obstacles can be over come in the end.

I know you have worked on your own car for a long time, but it will be worth it.

Seeing you on the road will be great inspiration for the rest of us still building.

Pops - Thanks for the tip, I found the photo of your belts...

But I couldn't see one of them fitted?

Does the top buckle just stay connected behind the seat.

Also found Mr T's great link about seat belts on your build too...

http://assets.dft.gov.uk/publication...e-vehicles.pdf

Got to love this forum, cheers, Paul.

|

13th January 2013, 06:34

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Just wanted to follow up on yesterday's post, as it had a knock on impact on this...

Frame & Bodywork - Take 3

The body shell has been resting on the frame work for a while now, but it hasn't "settled" any lower.

So I still had some issues with the driver's side not lining up the way I would have liked it to.

The good news is that whilst testing the seat belts I discovered one of the reasons for this...

Yes, the seat belt mounting bracket was fouling the bodywork on the driver's side.

This quickly settled any debate about whether, or not, I would try to use this bracket.

As out came the angle grinder, I then propped up the body & was quickly left with this.

I will remove the rest of the bracket when the body is off again properly.

While the angle grinder was out, I removed the lower seat belt bracket from the driver's side too.

As I've already trimmed the passenger floor pan to fit, the bracket on that side can wait.

I love the new Ribble approach of re-using the Spitfire body shell as it makes for an easier build.

However, that is no longer an option for me, so I will just make the most of what I have got.

So taking my frustrations out on the frame with an angle grinder was very therapeutic.

As there is no escaping the fact this frame work really is a [American Slang]POS[/Cussing]!

Note:

When Andy re-launches the Ribble Navigator (son of Cordite) these issues will be fixed.

Anyway, small rant out of the system and back to where removing this bracket got me...

Instantly, I had a much better fit all round, the door cut out area was much better.

The side of the bodywork now just covered the lowest frame rail.

Before:

After:

The body also came a lot closer to the pedal mounting plate (more on this later).

This just left the lower front corner on the driver's side as the remaining problem area.

I think I will be able to reclaim a couple of mm by removing the bracket on the left of this photo.

DonnySoutherner

DonnySoutherner previously mentioned that this was surplus to requirements anyway.

It is to bolt the body shell to the frame, but it is next to the plate where the pedals are bolted on.

However, it does sit proud of the rest of the area which makes it the last point of contact.

I did have a go at getting the angle grinder in there without removing the body.

But there was just no room to play with & I just got a face full of sparks for my trouble!

Joking aside, I was grateful for the fact I did have safety glasses on.

Got some domestic stuff to do now, but hope to have more to post later today, Paul.

Last edited by Paul L; 11th September 2019 at 08:58..

|

13th January 2013, 10:36

|

|

Senior Member

|

|

Join Date: Jul 2011

Location: Marmande 47200

Posts: 501

|

|

Quote:

Originally Posted by Paul L

Mr T - Outstanding reply.  Pops

Pops - Thanks for the tip, I found the photo of your belts...

But I couldn't see one of them fitted?

Does the top buckle just stay connected behind the seat.

Got to love this forum, cheers, Paul.

|

Havent completed the fit out but can explain how it woks so far.

Inertia mounted on plates at the back of the framw, one in each corner, The drivers side one sits on top and roles within the rear of the hump.

The passengers side is underslung due to body clearance. This runs freely over the fuel tank and connects to the harness behind the rear panel of the cockpit with the two shoulder straps exiting where the body tub lips over the frame. This give me about 200mm of travel forward so can reach all the knobs etc.

tried other options such as anchoring behind the seats but the angles and lengths of belts just didnt work out.

When I am home in a couple of weeks I will post pictures which should explain a lot more clearly.

Pops |

13th January 2013, 11:29

|

|

Senior Member

|

|

Join Date: Feb 2012

Location: Wembley, London

Posts: 5,058

|

|

Just got time for another quick "copy & paste" update before heading out for a family pub lunch...

Brake Master Cylinder - More Thoughts:

You may recall, that unbeknown to me, the Cordite body was not designed for Spitfire 1500 brakes.

The more time I spend trying to work out how to keep these, the more of a pain it becomes.

All the brake pipes were refurbished by the previous owner.

The system was also tested to MOT standard (& passed) by my local garage.

So here is where my thought process has got me so far...

Option #1

Fit the master cylinder "as is" and adjust the frame, bulk head & bonnet to accommodate it.

Below is a rough sketch* of the impact of this approach on each of these areas.

( * Don't look too closely for anything resembling scale or true perspective.  )

As you can see, a shed load of work and the distinct possibility of it looking like a dog's dinner.

So whilst this is a "don't fix want ain't broken" solution for the brakes, it is a no go for everything else.

Option #2

Replace the existing brake fluid reservoir with a "remote" one mounted to the adjacent bulk head.

I would also cut out slots in the fibre glass to mount the m/c directly to the frame plate below.

( As this would lower the unit a few mm and they all count. )

The existing brake fluid "out" lines would remain unchanged and stay fixed where they are.

But new brake lines would be needed from the remote reservoir to the fluid "in" points.

Although more research is needed as I'm struggling to find out if this is actually possible.

I know the Spitfire reservoir can be removed, but think it is basically a plastic "push in" fitting.

So I need to check if you can get a hose fitting to match that isn't the normal "screw in" type.

I think this approach would allow me to make a much smaller modification to the bulk head.

The recess should sit in between the existing frame rails, so they wouldn't need any work.

Obviously the whole point of the system is to reduce the height, so the bonnet would be OK too.

Option #3

Option #3

Replace the tandem master cylinder with an upgraded "traditional" single feed set up.

The twist would be to fit a "3 way" joint to keep the rest of the dual pipe work as is.

So the single pipe out from the new master cylinder would only be a few inches to the new joint.

Option #4

Option #4

Replace the m/c as in Option 3, but re-plumb the brake lines into a traditional line feed system.

Lots of pipe work required for this approach which is something I'm keen to avoid if possible.

Conclusion

I hope Option #2 will be possible, but realistically, Option #3 may be the most practical solution.

As always, happy to get feedback from those who know more about this than me.

Cheers, Paul.  Pops

Pops - Cheers Stuart, some photos would be a big help, thanks.

Last edited by Paul L; 11th September 2019 at 09:08..

|

13th January 2013, 17:35

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

It'd be option 1 for me: Notching the frame isn't difficult, I had to modify mine to fit the instruments where I wanted them and recessing the bulkhead is also pretty straightforward; a fibreglass power bulge above the master cylinder wouldn't look out of place - a half sized American football would probably be about the right size to use as a former; and, above all, I'd want to be absolutely certain I had working brakes.

Oh, and I've even found a specialist company that sells purpose made 100mm formers to mould the power bulge from -

http://www.ebay.co.uk/itm/New-Dog-Sq...item3f1a46f215 |

|

Currently Active Users Viewing This Thread: 5 (0 members and 5 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 23:49.

|