|

|

| Vintage and Classic Roadster Kit Car Builds For Vintage and Classic era kit cars. Post your build reports, problems and progress here |

27th October 2018, 19:30

|

|

Senior Member

|

|

Join Date: May 2009

Location: POOLE , DORSET

Posts: 2,200

|

|

slotted raised countersunk fixings look cool too ....I try to use slotted fixings in visual areas as opposed to posi screws etc . when I can ...just one of my things ...

|

2nd November 2018, 06:39

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Feeling Eclipsed!

Feeling Eclipsed!

I belong to a Facebook group titled 'Homebuilt Cars, from scratch or kits', and am in awe of what some members are achieving across the pond, unhindered by SVA. Today I came across this video which features a Stateside Monaco of sorts.

Brilliant!

Regards, Mick

|

2nd November 2018, 06:57

|

|

Senior Member

|

|

Join Date: Jan 2014

Location: Egham, Surrey

Posts: 1,780

|

|

Quote:

Originally Posted by lancelot link

slotted raised countersunk fixings look cool too ....I try to use slotted fixings in visual areas as opposed to posi screws etc . when I can ...just one of my things ...

|

Just make sure all the slot heads are pointing in the same direction. Stepfather rebuilt an Austin A40 Devon pickup, the rear deck was wood and every slot head screw was in alignment, really was a finishing detail and it was amazing how many people noticed it. |

2nd November 2018, 06:55

|

|

Senior Member

|

|

Join Date: Jul 2011

Posts: 5,328

|

|

Utterly bonkers. I love it.

|

2nd November 2018, 10:51

|

|

Senior Member

|

|

Join Date: Jun 2015

Posts: 1,401

|

|

Fastidious fixings

|

6th November 2018, 07:15

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Some Progress

Some Progress

Progress has been slow over the last couple of weeks whilst I've concentrated on the back brakes. To make absolutely sure that my demon handbrake effort multiplier is mounted optimally, I realised that the rest of the linkage back to the shoes would need to be in place. I checked my mound of parts to find that I had no backplate levers, so these I ordered. I examined the four drums and decided they were too worn to use in that condition. When building the A352 I'd come to the same conclusion and had them skimmed and faced locally. I just was about to march down to the engineering workshop with them when I thought to check the price of new ones, which was considerably less than I'd paid for machining. These I ordered. Once they'd arrived I assembled my bits, jacked up the back end and removed the wheels, only to find no adjusters  . More ordering, more delay. . More ordering, more delay.

In the meantime, having noticed some de-lamination in the edges of my plywood 'floors', I purchased some superior marine ply (buy cheap, pay twice!), removed the existing which made handy templates, and cut and fitted the new ones. This time I corrected a previous omission and screwed on a vertical back for the luggage area behind the seats. Thinking that this might drum, I made a pair of angled brackets to prevent this. Excuse rubbish picture.

Yesterday, at long last, all the new brake bits were to hand, and were successfully fitted.

Another Spitfire based Monaco had come up for sale in the Moss FB group, so I gave the vendor a ring for a chat about a possible viewing for ideas, as it was dismantled after being on the road. In particular, I was interested in the windscreen from which to take a paper patten as my efforts were rubbish. He said he'd have a look for it and get back to me. However, in the interim, I'd scrolled back through this thread and decided to go down this route....

Moss (bizarrely) in Bristol only had one in stock, and this I received yesterday. I'm hoping that I can get the second at the Classic Car Show this Friday, especially if there's a 'show deal' available  . .

Regards, Mick

|

6th November 2018, 08:21

|

|

Senior Member

|

|

Join Date: Jan 2014

Location: Egham, Surrey

Posts: 1,780

|

|

If you give the edges of the plywood a coat of grp resin it will stop any water creeping in later on. In fact, it is probably worth giving all the plywood a coat.

|

8th November 2018, 07:18

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Small Steps

Small Steps

The weather hasn't been helping, but on Tuesday I trial-fitted the radiator by standing it on a wooden block, fitting the top and bottom hoses, and fabricating brackets to locate it to the U shaped support which bolts to the frame. The upright arms of this provide attachment points for the engine bay splash guards on a Spitfire, not needed on the open-wheeler Monaco, so I'll cut off the redundant portions. Not really worth a picture, I may post one once everything's in place.

Looking at the weather forecast I realised that plonking the body on the grass wasn't going to happen so I set to fitting the pedal box with the body on the chassis. The footwell side had good access through my master cylinder servicing hole, but the engine bay side was severely restricted by the rear SU which had worn holes in my forearm by the time I'd finished. This was a very fiddly job as the ¼" UNF bolts had to be the exact correct length so that they didn't interfere with the pedals. The solid part of their shanks also needed the die running down them to get them fully home in the captive nuts. After a couple of hours trial and success all was finally in place. Excuse yet another crap photo'.

Filling that lower hole will definitely have to wait until the body's off.

Regards, Mick

|

9th November 2018, 06:52

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

A Slow Day

A Slow Day

Yesterday I fettled the top radiator supports a little more, and trial fitted them: all good. The bottom supports will need to be more substantial, but a search of my metal heap failed to locate anything suitable - the 3mm steel falling into the 'overkill' bracket. Ebay will doubtless come to the rescue.

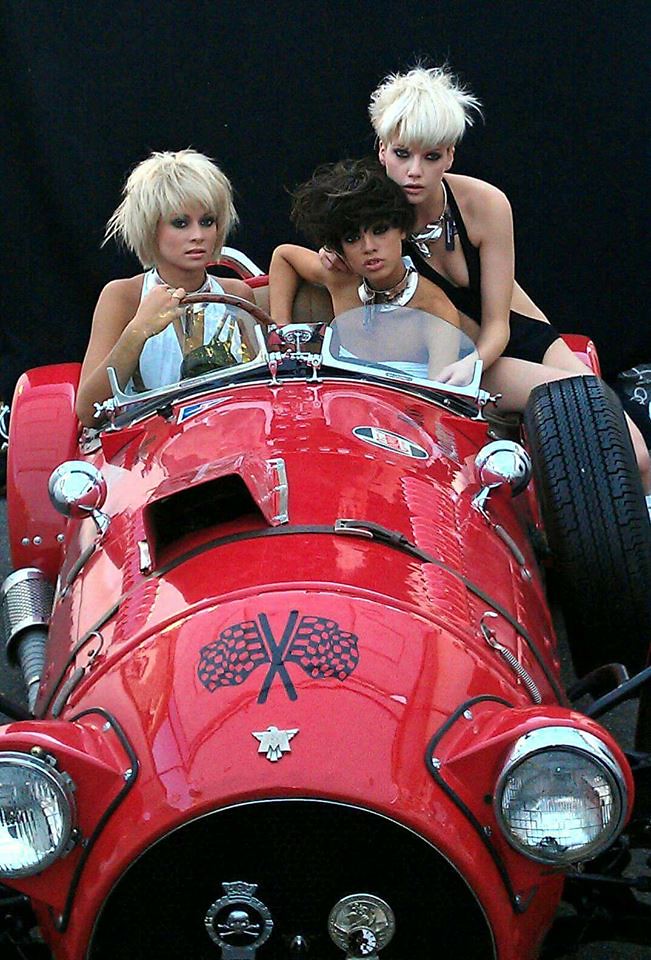

I turned my attention to the aeroscreen supports, which don't seem man enough for the job. The two holes through which each is mounted to the body were between 4 & 5mm diameter (see the 'Bananarama' picture above) and at right angles to the stresses they're supposed to resist. I ran my 5mm tap through them which removed only the chrome plating. More Ebaying will provide A2 countersunk screws which, when fitted, will perform as studs. Small pedestals, again as in the picture, will be needed for the outer mountings so I trial made one from 2" of ¾" box with 45° ends. The light was fading by then so I called it a day.

The one really bright spot was the nice man bringing this  . I hope its application will be soon! . I hope its application will be soon!

Regards, Mick

|

11th November 2018, 13:05

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Small Steps

Small Steps

Yesterday morning I wandered down to the cave through the downpour with my newly delivered A2 M5 countersunk bolts, fully intending to trial fit the first aeroscreen (I'd ordered the second on Friday using the money I saved by not going to the Classic Car Show - a whopping £33 entrance + the train fare = 60 quid. In contrast, the Motorbike Show, same venue Monday week £15 entrance). Enthusiasm at a low ebb, due to the foul weather, I decided to limit myself to something simple. Blanking off the hole in the driver's side engine bulkhead seemed to fit the bill. I'd previously thought of filling it but, on reflection, simply fitting an ally plate each side would do as good a job. I cut two 15 x 10 ally rectangles, ran a bead of Sikaflex around one edge of each and, after roughing up the GRP and wiping with acetone, gently pressed each into position. Job done. Even worse photo' alert!

Today, enthusiasm was higher, and I set to fettling my demon aeroscreen pedestals. The above mentioned bolts needed cutting to length, and the 6mm holes, through which the pedestals themselves will be mounted to the body, drilling. I then trial assembled them. I think the supports are little more than pathetic, given the job they were so say 'designed' to do, definitely form over function. They wouldn't last five minutes on a Blower Bentley clocking the ton on the Brooklands banking! Anyway, I'm stuck with them so will have to press on regardless.

You can see from this marginally less rubbish photo' that the shape of the casting prevents the bolts from sitting right down. Hex or button heads would be even uglier  . .

After paying my 1100 respects, I decided to have yet another look at the wing supports. This was about the fourth time as they were clearly intended for a different chassis frame, and I'd feebly put them back in store each time after unsatisfactorily offering them up. This time, however, I was more decisive and decided to make them fit. Two of the four each side could be used, with a little imagination, as they were. One each for the front and rear wings. A third I cold set at both ends in the vice until it also was serviceable. The fourth, however, had to be cut and will need a new body end plate welding on. They're not really worth a photo' until they're in situ. Pleased with this unexpected outcome, I called it a day.

Regards, Mick

|

12th November 2018, 07:56

|

|

Senior Member

|

|

Join Date: Sep 2011

Location: Teesdale

Posts: 238

|

|

Quote:

Originally Posted by Mick O'Malley

You can see from this marginally less rubbish photo' that the shape of the casting prevents the bolts from sitting right down. Hex or button heads would be even uglier  . .

|

Hi Mick

Would countersunk bolts such as these fit?

https://www.ebay.co.uk/itm/M4-M5-M6-....c101006.m3226 |

27th November 2018, 06:59

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

It's beginning to look like a car...

It's beginning to look like a car...

Quote:

Originally Posted by Althecate1

|

Thanks for that, but the shape of the casting precludes any stock fastening sitting nicely.

Yesterday, as planned, I finished off the front off-side mudguard mounting. It proved even fiddlier than the other three, but with plenty of swearing it eventually sat satisfactorily. Wheeling the beast, now looking the part, right out of the cave was confidence boosting. I had a brief daydream of a Christmas Day blast which reality soon popped. Maybe 2019?

The seats were next on the agenda. I used the plywood+foam+vinyl method on both my Pre-Lit Westie and Mk1 Marlin Roadster with acceptable (and inexpensive!) results. However, both those had square tops to the back which made neatly stapling the vinyl straightforward. I think I'll ask my seamstress friend, who made my A352 seat covers, for advice on a tidy solution to the curved top. I made the first rough cuts of the firm 3" foam, sat it all in place, and inserted myself. It's never going to have Rolls Royce comfort standards due to the cramped cockpit, but I found it acceptable. The newly cut foam looks very untidy but the vinyl smooths a multitude of sins.

I dug out my roll of vinyl, spray adhesive and vinyl glue as well for a quick pose, then called it a day. Looking at the weather forecast for the rest of the week, I think operations will have to be suspended.

Regard, Mick

|

27th November 2018, 07:14

|

|

Senior Member

|

|

Join Date: Jan 2014

Location: Egham, Surrey

Posts: 1,780

|

|

You can use a belt sander to smooth the foam. Very easy and quick to do and makes a big difference to the finished appearance.

|

4th December 2018, 08:25

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Tiny Steps...

Tiny Steps...

After a break of a week, during which one of my sons came to stay (and the weather was awful!), I got back down the cave yesterday. The rain meant that the long awaited body-off session was impractical, so I decided to knock off the last wing-related tasks.

Shamelessly plagiarising Maggie Shapland's rear steady bars, I cut, drilled and bent two lengths of my much-used aluminium strips to suit. As attachment with Dreadnought rivets will be post-paint I stuck one on with gaffa tape loops to show the fitment.

Turning my attention to the front ends of the rear 'guards, I decided to bolt them through the body sides using M6 button heads with rubber fuel hose spacer sleeves and small ally angle brackets 4mm rivetted to the wings. This again required a bit of removing and replacing but I was pleased with the result. Yet another crap photo' alert!

The depressing weather then had me scurrying indoors, happy to have nibbled away another tiny part of the build.

Regards, Mick

|

9th December 2018, 07:56

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Rain Stops Play - Almost

Rain Stops Play - Almost

Despite wandering down to the cave every morning since my last post, I've not achieved much, the sound of the rain beating on the corrugated iron roof being hardly inspirational. I did notice that, with the strong wind, water was finding its way into the back of the project through the holes and some even being blown into the cockpit. I first stuck small strips of gaffa tape over the holes, then bungeed a groundsheet over most of the back end.

As the dry front end was still accessible, I decided to address the problem of cutting the body and bonnet for the twin SUs and their filters. I'd replaced the chunk cut out by a previous owner to clear the DCOE which it came with, now sold. It was obvious that major surgery would be required, even if I had inlet trumpets rather than filters. I trawled through my collection of Monaco pictures, once again alighting on that of Maggie Shapland's, which is powered by an RS2000 engine with a DCD Weber, whose filter pokes neatly though the upper surface of the bonnet.

An internet search revealed that a suitable manifold is available  . I e-mailed Moss, whose web site shows a picture of this installation, but, after waiting a frustrating week without reply, sourced and bought one from a Weber factors in California. Serendipity then came to the rescue yet again, in the shape of a 28/36 DCD jetted for a pre-crossflow 1500 Ford. No bids were placed, so I contacted the owner with an offer, which was accepted, and drove the 30 miles up to Worcester and collected it from another rabid geriatric petrol head. Crap photo' alert! . I e-mailed Moss, whose web site shows a picture of this installation, but, after waiting a frustrating week without reply, sourced and bought one from a Weber factors in California. Serendipity then came to the rescue yet again, in the shape of a 28/36 DCD jetted for a pre-crossflow 1500 Ford. No bids were placed, so I contacted the owner with an offer, which was accepted, and drove the 30 miles up to Worcester and collected it from another rabid geriatric petrol head. Crap photo' alert!

Remembering that I'd neglected to make provision for a throttle cable in my transverse pedal box support. I removed it after carefully marking where the cable hole was needed, and drilled it with a 2.5mm bit. The housing for the outer will have to be from a couple of thicknesses of ally rivetted to the top of the support. Once my Ebay cable arrives, and I've measured the ferrule, I can do this.

That was it for the week. With a decent forecast, albeit cold, for the next few days, I'm hopeful of more progress  . .

Regards, Mick

Last edited by Mick O'Malley; 9th December 2018 at 11:24..

|

9th December 2018, 12:19

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Why not, if the sun's out?

Why not, if the sun's out?

I hadn't planned on doing any work today, but the sight of the blue sky and sun lured me down to the cave. What to do? I'd removed the twin SUs in the week and, on replacing the bonnet, remembered that the radiator filler pipe and cap would also necessitate bonnet surgery. I 8mm drilled the corners of the hole outline, and jigsawed them together. Replacing the bonnet showed that my measurements hadn't been too bad. This picture also shows the partially repaired DCOE butchery.

I offered up the GRP air scoop which came with the kit - way too big - and briefly considered cutting it down before deciding to make an ally cover. I remembered doing similar in '91 to the bonnet of my Dutton P1, my third kit car.

I seem to have gone a bit mad with the rivets!

Using the tried and tested CAD method, I mocked up a cover, transferred the outline and marked the fold lines on an ally sheet offcut. Having cut it out, getting the folds right proved a bit of a challenge, but perseverance paid off. I then realised that I'd made it shiny side out, which I decided would have to do. I might distress it sometime, if the mood takes me. As it won't be rivetted together and in place until after painting, I put it in the shed with its other 'to be fitted later' ally brethren.

Happy to have achieved, I called it a day.

Regards, Mick

Last edited by Mick O'Malley; 9th December 2018 at 12:23..

|

15th December 2018, 08:42

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

The list gets a little shorter.....

The list gets a little shorter.....

This last week or so I've nibbled away at the remaining tasks. I had help one day, removed the body and mounted the radius arm brackets at long last. The next day I spent a good while carefully measuring and re-measuring for the location of my handbrake multiplier bracket, and drilled its mounting holes. However, even with the car up on axle stands I couldn't fit it, access is just too limited - it'll have to wait until the body's off again. I neglected to take pictures of these operations.

Armed with a picture of a Monaco, I made the trip over to see the guys who'd sprayed the A352 and explained that I'd deliver it with the wings and bonnet etc. dismantled. We danced around a price and agreed 1st March as a start date. Cool!

I made a few on line purchases for my new Weber installation: manifold gasket; base gasket; air filter gasket. These have now all arrived, as has the throttle cable, whose locating hole in the transverse support I also drilled. Again no pictures.

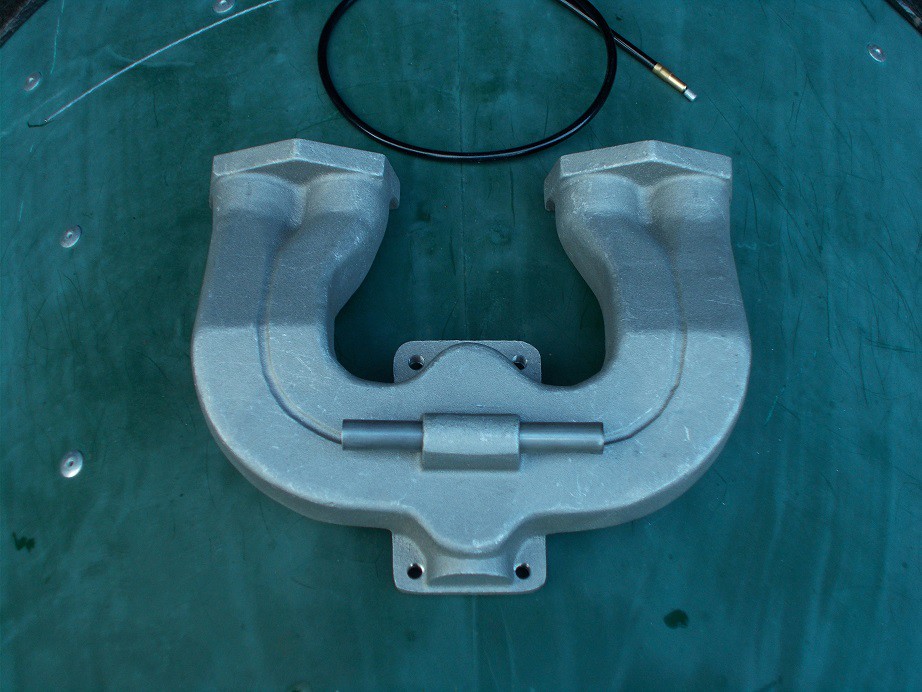

On Thursday at about 0830 the nice lady from UPS delivered my manifold, posted in California on Tuesday. Amazing service! It's a beautiful casting, I'm absolutely thrilled with it  . .

I now need an air filter so that I can trial fit it all for bonnet surgery. They're very expensive new so I'm hoping to get lucky on Ebay......

Regards, Mick

|

12th October 2021, 14:57

|

|

Senior Member

|

|

Join Date: Nov 2012

Posts: 845

|

|

Quote:

Originally Posted by Mick O'Malley

I remembered doing similar in '91 to the bonnet of my Dutton P1, my third kit car.

I seem to have gone a bit mad with the rivets!

Regards, Mick

|

I bought this P1 in late 1990 for only £80, as the owner had enthusiastically T-Boned a Chevette at the end of his road. I cut off the 1" box tubular front suspension bay, took it to my welder, and had a new one made for £120. A special builder friend welded it back on for pocket money  . I used it for six months and sold it to a club member for £600. He found he couldn't fit in it so I bought it back for the same money, used it some more and passed it on again. Fast forward 30 odd years and it's appeared, fully restored, on Ebay. A nice little sportster, just as long as you're skinny! . I used it for six months and sold it to a club member for £600. He found he couldn't fit in it so I bought it back for the same money, used it some more and passed it on again. Fast forward 30 odd years and it's appeared, fully restored, on Ebay. A nice little sportster, just as long as you're skinny!

Regards, Mick |

20th December 2018, 11:30

|

|

Senior Member

|

|

Join Date: Apr 2011

Posts: 282

|

|

Oh I do love to see the art of the true 'Special' builder is alive and well. Respect.

Last edited by Dpaz; 22nd December 2018 at 20:41..

Reason: spelling

|

|

Currently Active Users Viewing This Thread: 349 (0 members and 349 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT +0. The time now is 01:17.

|