I've spent the bulk of the weekend working in the garden & general house tidying.

Part of that involved moving Cordite parts from the back garden to the front drive.

So I have a little bit of progress to report...

Cleaning:

I gave the Rolling Chassis a quick "wash & brush up" to get the bulk of the dust & dirt off.

But I need to get some more 'Gunk' to sort out the engine, clutch housing, gearbox, etc.

I also hope going round these with a torque wrench will stop the various 'weeping' points.

At some point I will need to clean the drive itself as that has become a big drip trap. : (

However, cleaning & daylight gives a much better impression of what remains of my donor.

Don't tell

you know who that there is some

over spray to deal with on the chassis too. ; )

Internal Framework & Body Work:

Internal Framework & Body Work:

This was all done in a bit of a rush just to tidy up & will be done properly another day.

But it was still a good chance to get a better idea of what I need to do in the future.

Before I tried to fit the rear frame I needed to remove the cross brace added for transportation.

After years of borrowing angle grinders from my mate, I finally bought a small one of my own.

So whilst not strictly a true cost of the build, it is something very useful to have around.

I will keep the "off cut" as I'm sure it will come in handy later on in the build somewhere.

Now I had rested the front frame on the chassis when the body shell was removed.

In daylight it is clear that all the holes do not line up, but I think this should be an easy fix.

The rear frame only has two fixing points pre-drilled for the raised rear mounting points.

Again, I don't think it will take much work to get them bolted into place either.

Based on other builds I think you drill holes to bolt the frame to the main chassis rail.

Here is

DonnySoutherner's frame with bolts through it at the front.

( There are a matching pair at the back end of the frame on his build too. )

In the mean time, here are both my frames just resting in place:

The first question I have is does the frame re-use the original Spitfire rubber mountings?

There were a mixture of plain rubber & rubber with metal "caps" on my donor.

Whilst one was missing (probably stuck to body shell), I've found a new one in a box of bits.

The answer to this question will help me with my next issue, which is the fuel line.

If the rear frame sits directly on the chassis, the fuel line will need to be lowered.

The line currently sits on the side of the main chassis rail & the rear frame just hits it.

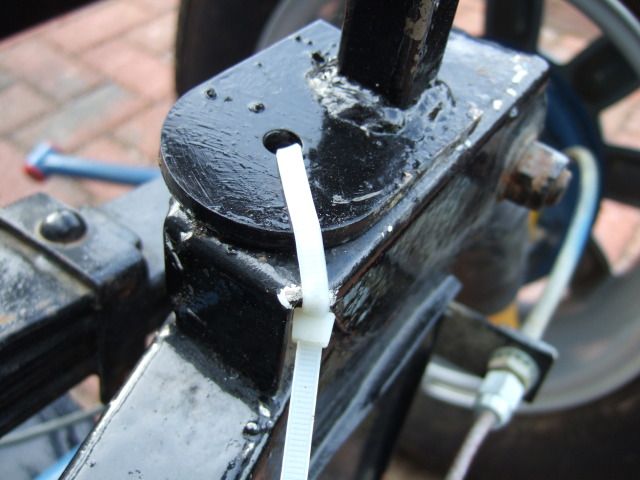

As we were in a rush I simply used zip ties to hold the front & back roughly in place.

I assume the two parts of the frame should be joined together

before final fitting.

Because my rough & ready fixing meant that I couldn't line up the top & bottom brackets.

( Something that I am sure will not be a problem when I have time to look at it. )

Although it does appear that

AndyP57 has a different bracket on his frame??

Here are my top and bottom brackets:

And here are the only photos I could find of the frames joined together.

I just need to make sure I get the two frame parts on the correct side of each other.

Even though the frame wasn't quite right, it was time to put the body on.

Unfortunately it quickly became clear the frame had a knock on impact on this.

I couldn't get the dash or the bottom of the front bulk head in place.

But wasn't going to force, or start cutting, anything at this stage.

That was as much as I had time for yesterday, but I did some more this morning.

I moved the front foot wells, gearbox cover & hand brake mount to rest in place.

As there is no where to mount the rear exhaust pipes (yet) I just left them on the ground.

This was to give me a rough idea how far they would stick out beyond the bodywork.

They are not too bad, although I still might shorten the single mid section pipe a tad.

Finally I put the bonnet on, but quickly remembered the front chassis rails are in the way.

But it couldn't stay in the garden, so I held it in place with some 'tie down' straps.

Which was good enough for me to be able to pull the cover over the top.

Even though it is only temporary, this has been a big help in 'tidying up'.

[Rolf Harris]

Can you tell what it is yet? [/Rolf Harris]

I've been updating these words & photos as I've been going along.

But I still have more domestic chores to finish today, so I'll leave it at that for now.

I'm not going to touch the car now until after our big bash next Saturday.

Until then, take care, Paul.