Tiresome Tuesday - Part 2:

Gear Box Cover:

However, I wanted to add an extra screw on the horizontal face, so the cover came off again.

And a "catch" was added to both sides.

Before the cover went on again.

And the bulkhead was propped up.

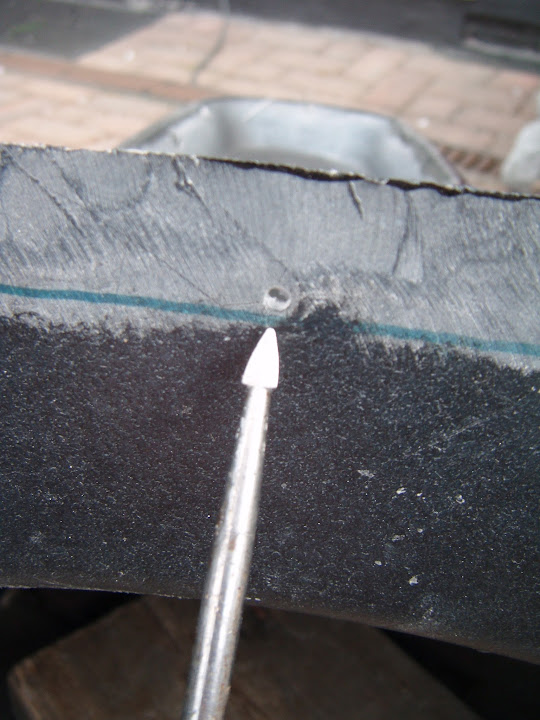

So I could drill a pilot hole through the catch and the cover.

Then it the cover had to come off again, so I could remove the catch and drill out the holes to the right size.

Then I could refit the cover yet again to test fit the extra screws.

While the bulkhead had been propped up, I also marked the position of the top edges of the bulkhead onto the cover.

The cover comes with 3 pilot holes drilled in this top area and the two outside ones were going to be no problem.

But the centre one was too low compare to the metal available to screw into.

My donor car came with this small plate for this hole, so I used that to mark up the cover.

Then the three holes were drilled out to the right size in both the cover and the bulkhead.

Then I decided to add an extra bolt in the middle of this vertical face around here as well.

( As this ties in with the number of fixings my donor car had on the cover. )

With the holes drilled out, the bolts will look like this when fitted.

So after messing about for a very long time, all the holes required to fit the cover are finally done.

Now I just need to tidy up all these new holes and touch up the surrounding paint work, plus clean up some of the old catches.

Note:

I've trawled through this build thread to find these photos of the original bulkhead holes for the cover.

( Sorry the first photo is rubbish. )

Most of this mess was simply cut out and new metal was welded in.

Which is why I had to drill every hole required for the cover at this stage.

At least this job was a lot easier to do with the bulkhead off the chassis.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Overall this was definitely another slow progress day, but at least it was still some progress.

Until next time, take care, Paul.